High exhaust check valve of critical and supercritical thermal power generating set valve

A technology for thermal power units and check valves, applied in valve details, control valves, valve devices, etc., can solve problems such as no guarantee of closing time, inability to automatically open, etc., achieving light weight, good force resistance performance, and small pipeline load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

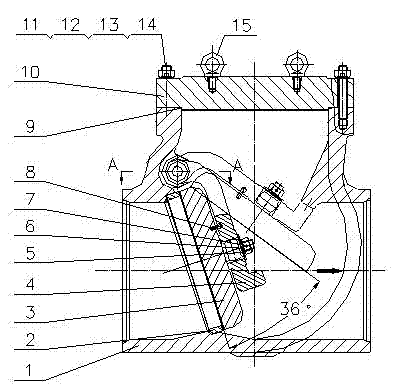

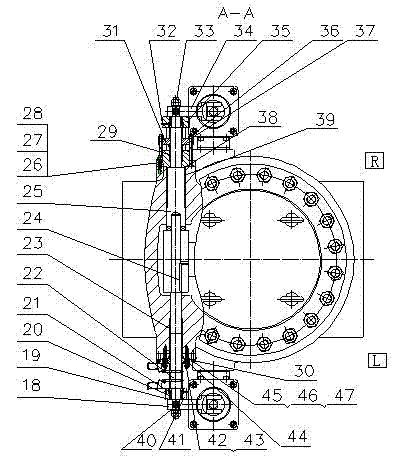

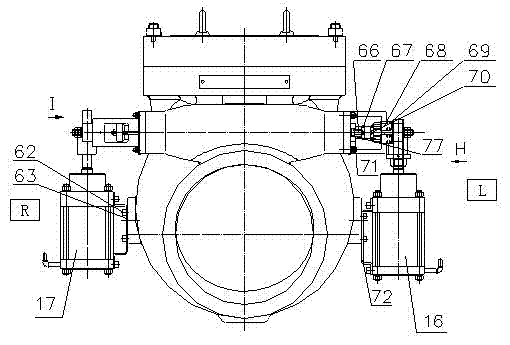

[0030] Combine Figure 1~Figure 8 , The structure of the high-discharge check valve of the present invention is further explained:

[0031] (1) The rocker arm 4, the disc 3, the split pin 7, the disc nut 6, the disc nut gasket 5, and the anti-rotation pin 8 are assembled into a component and placed in the valve body 1, and the valve seat 2 is welded to the valve body 1;

[0032] (2) Forced opening shaft 22, left sleeve 23, key 24 is installed in the left shaft pin hole of valve body 1 (see figure 2 ), connected to the rocker 4 component. Insert the forced closing shaft 25 and the right shaft sleeve 39 on the right side of the shaft pin hole of the valve body 1;

[0033] (3) Packing 29 is installed in the shaft pin holes on both sides of valve body 1, and right bracket stud 28 and left bracket stud 46 are screwed into both sides of valve body 1. Screw in the right packing pressure plate stud 36 on the right bracket 35, install the right packing pressure plate 31, the packing 29, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com