Heat compensation circuit and method for executing in multi-phase DC/DC converter

A technology of DC converters and converters, which is applied in the direction of output power conversion devices, conversion equipment without intermediate conversion to AC, electrical components, etc., which can solve the problems of reducing system reliability and performance. Increase ripple and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

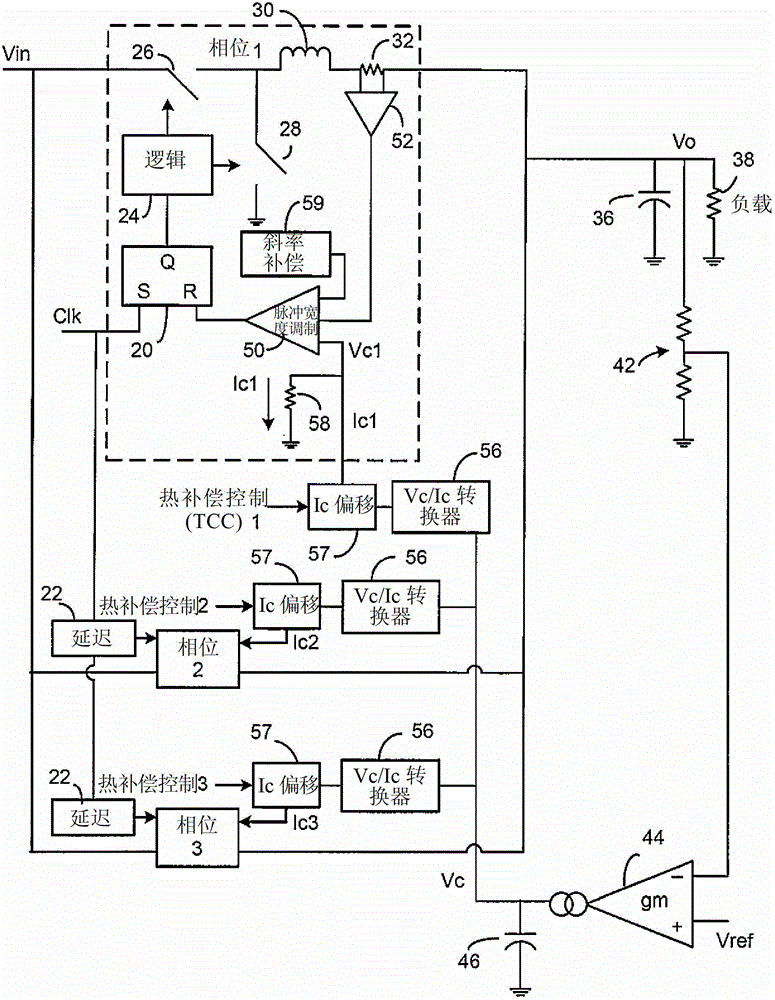

[0016] figure 1 One type of multiphase DC / DC converter using thermal compensation according to one embodiment of the invention is illustrated. Many other types of multiphase converters can also benefit from the invention. The particular type of converter shown is a peak current mode controlled converter.

[0017] figure 1 The operation of the converter section of is conventional and proceeds as follows.

[0018] figure 1 Three phases (Phase 1 to Phase 3) are shown in , but the invention is applicable to any number of phases. For simplicity, only components in Phase 1 are shown. A clock (Clk) signal of each phase is applied to a set input of the RS flip-flop 20 . Each Clk signal is phase-delayed relative to other signals by delay circuit 22 .

[0019] The setting of RS flip-flop 20 produces a high signal at its Q output. In response, logic circuit 24 turns transistor switch 26 on and synchronous rectifier switch 28 off. Both switches can be MOSFETs or other transistors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com