Minitype electromagnetic valve

A solenoid valve, small technology, applied in circuits, valve details, valve devices, etc., can solve the problems of coil heating and coil resistance increase, and achieve the effect of suppressing heat generation, reducing resistance value, and improving insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0063] Composition of Small Solenoid Valve

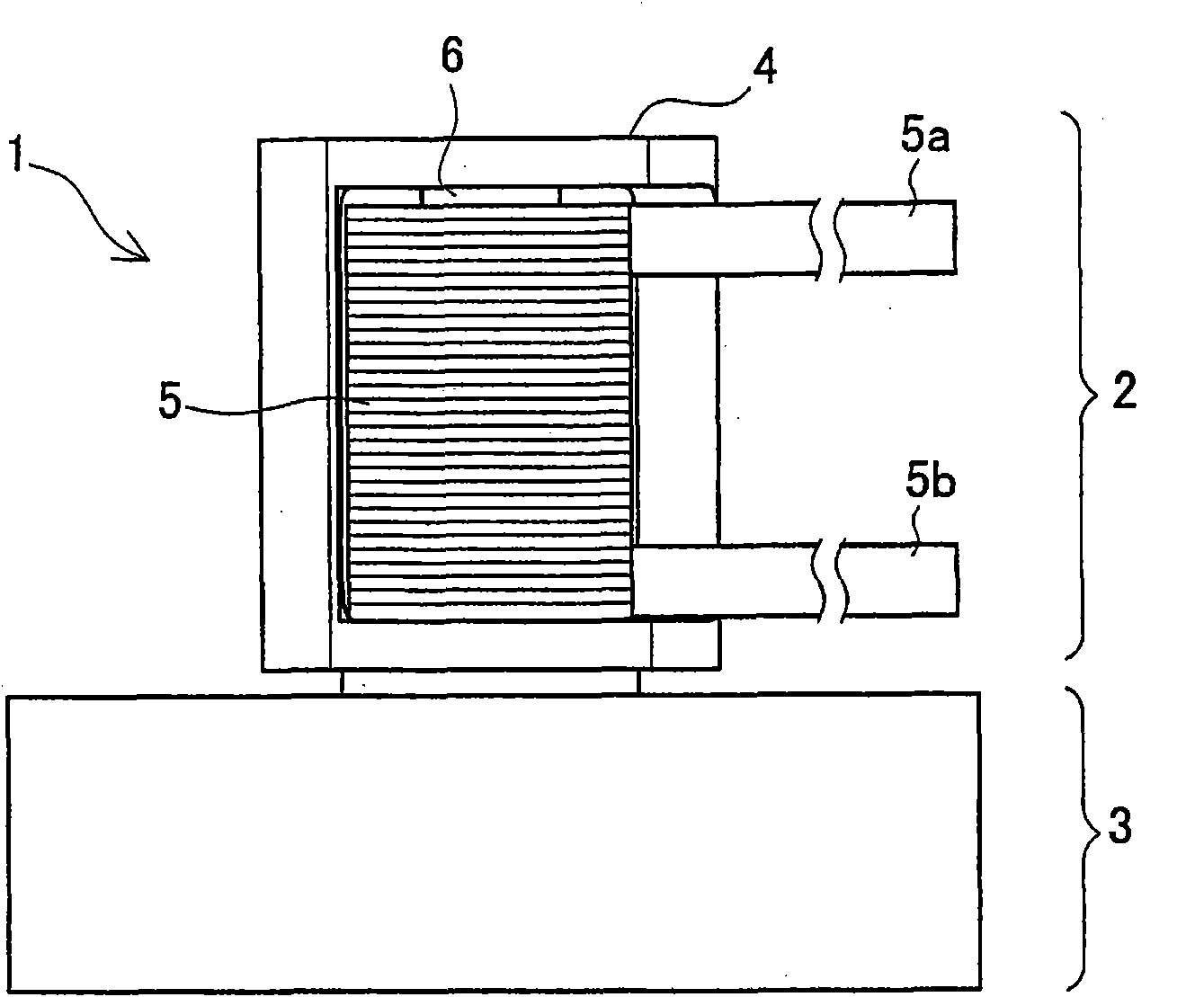

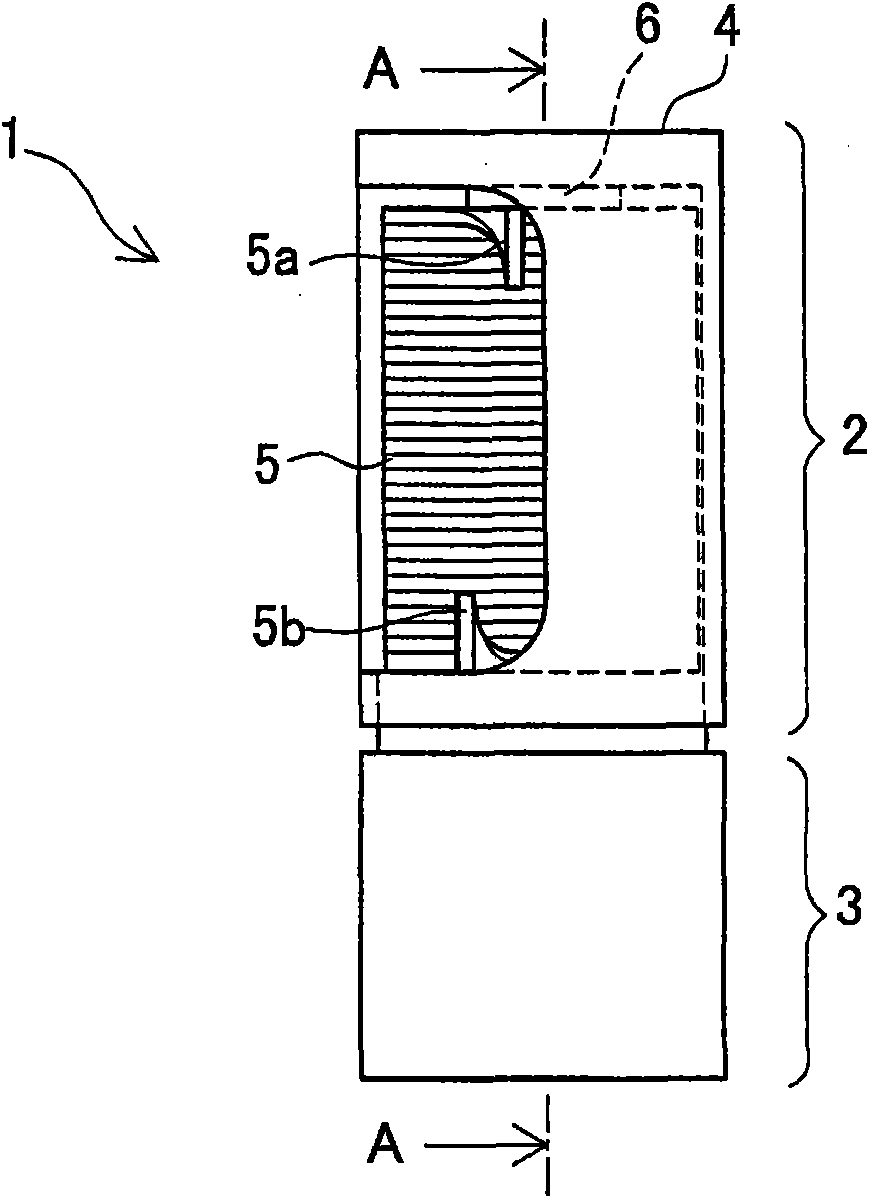

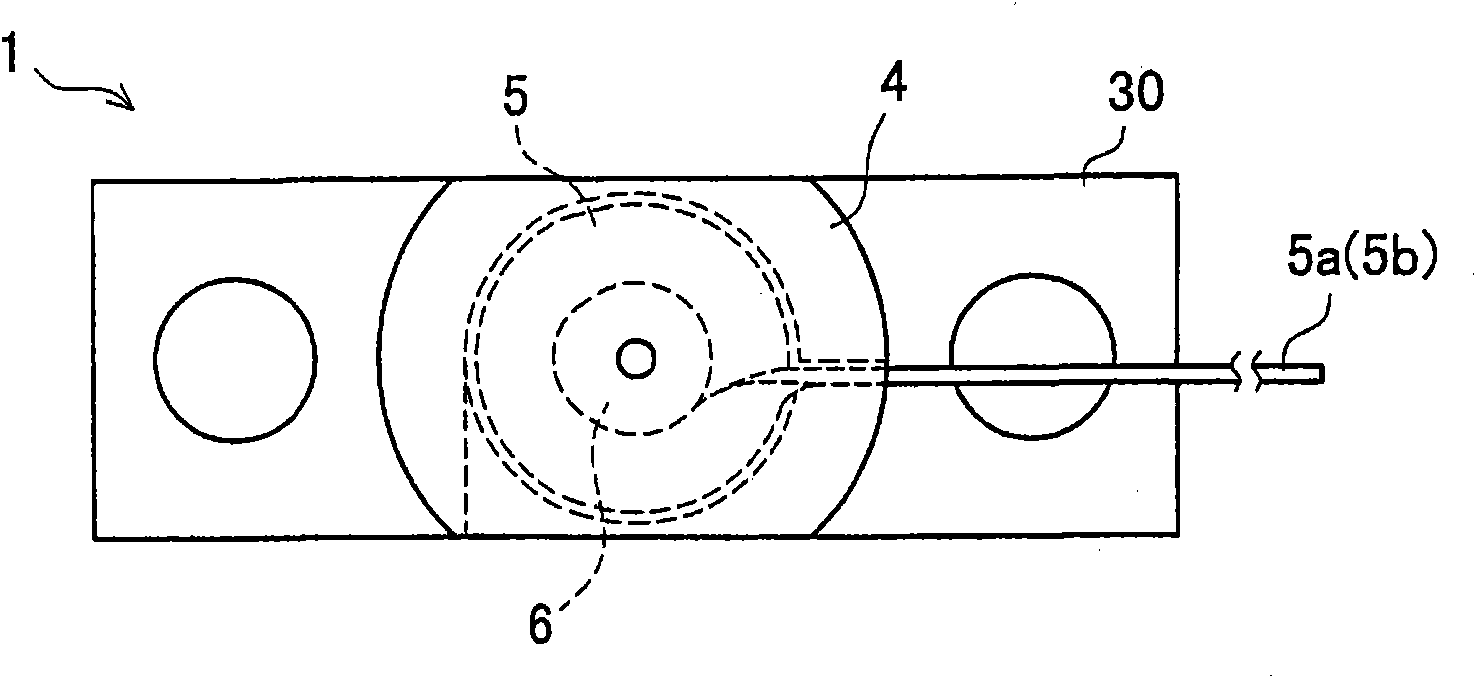

[0064] figure 1 A front view of the small solenoid valve 1 is shown. figure 2 Indicates the right view. image 3 Indicates a top view. Figure 4 Indicates the upper perspective view of the appearance. Figure 5 An exploded perspective view of the small solenoid valve 1 is shown. Figure 15 express figure 2 Cutaway view of AA.

[0065] Such as figure 1 As shown, the small solenoid valve 1 is composed of a solenoid part 2 and a main body part 3 .

[0066] Such as Figure 15 As shown, a first flow path 31 and a second flow path 32 are formed inside the valve body 30 of the main body portion 3 , and the first flow path 31 and the second flow path 32 communicate with the valve chamber 33 . A valve hole 35 is formed in a communication portion where the second flow path 32 communicates with the valve chamber 33 , and a valve seat 34 is formed in a peripheral portion of the valve hole 35 .

[0067] Solenoid section 2 as Figu...

no. 2 approach

[0108] Compared with the small solenoid valve 1 of the first embodiment, the small electromagnetic integrated valve 80 of the second embodiment has a width of the valve body 30 of 11 mm and a width of the solenoid part 2 of 10 mm. There is no difference, therefore, the small solenoid valve 1 will not be described.

[0109] Figure 17 A perspective view showing the appearance of the small solenoid integrated valve 80 . Figure 18 It shows a side view of the small solenoid integrated valve 80 .

[0110] Such as Figure 17 and Figure 18 As shown, in the small solenoid integrated valve 80 , the small solenoid valves 1A, 1B, 1C, and 1D are arranged facing the same direction. In the small solenoid valves 1A, 1B, 1C, and 1D, the width of the valve main body is larger than the width of the solenoid portion, so the solenoid portions do not contact each other.

[0111] The small solenoid valves 1A, 1B, 1C, and 1D face the same direction, so the coil insertion hole 40B of the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com