Method for performing weight injection processing on wood

A wood and airtight technology, applied in the direction of pressure impregnation, etc., can solve the problems of long processing time, slow speed, waste of raw materials, etc., and achieve the effect of reducing the impregnation time, reducing production costs, and reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings.

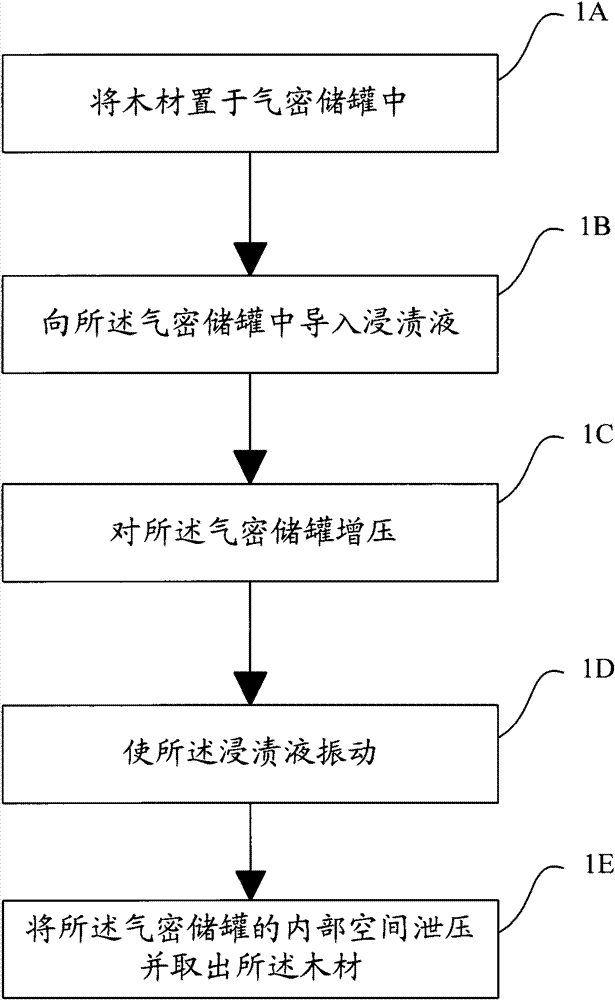

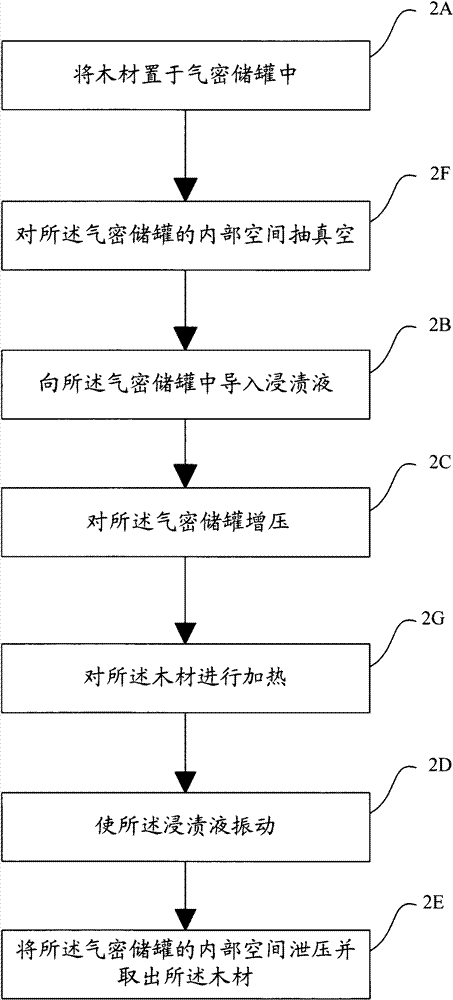

[0023] figure 1 A flow chart of an embodiment of the present invention is shown, in which the method for processing wood with emphasis includes:

[0024] Step 1A, place the wood in an airtight storage tank;

[0025] In step 1B, the impregnating liquid is introduced into the airtight storage tank. In a preferred embodiment, the total amount of the introduced impregnating liquid completely immerses the wood, so that the impregnating liquid can penetrate into the interior of the wood from all sides. The dipping liquid includes anticorrosive liquid, flame retardant liquid, dyeing liquid or other liquids.

[0026] Step 1C, pressurize the airtight storage tank. Due to the high external pressure, the impregnating liquid on the outside of the wood will be pressed into the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com