Double-shot molding mold for forming double-face rubber coated product

A technology for two-color injection molding and rubber products, which is applied in the field of two-color injection molds for forming double-coated rubber products. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

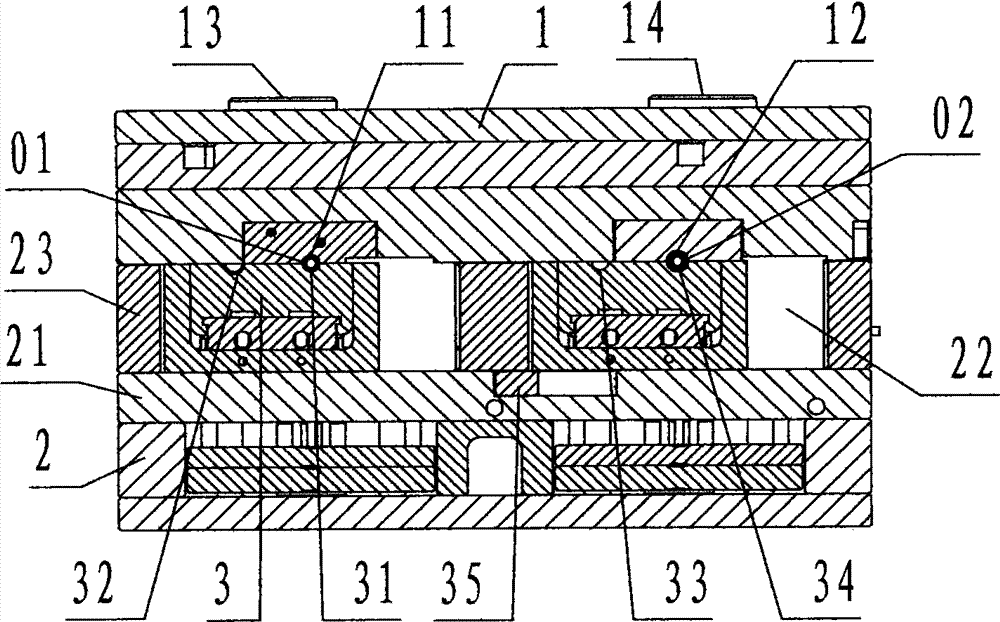

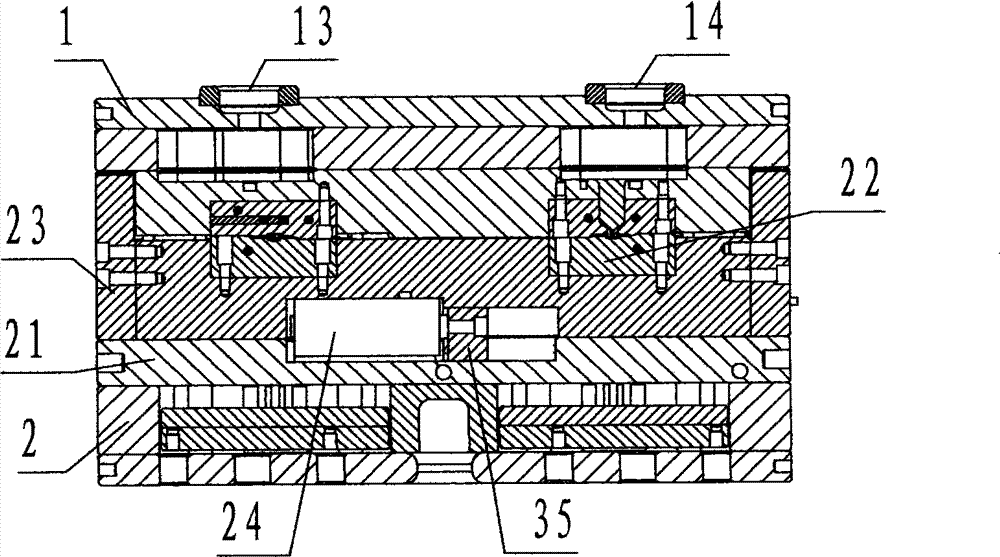

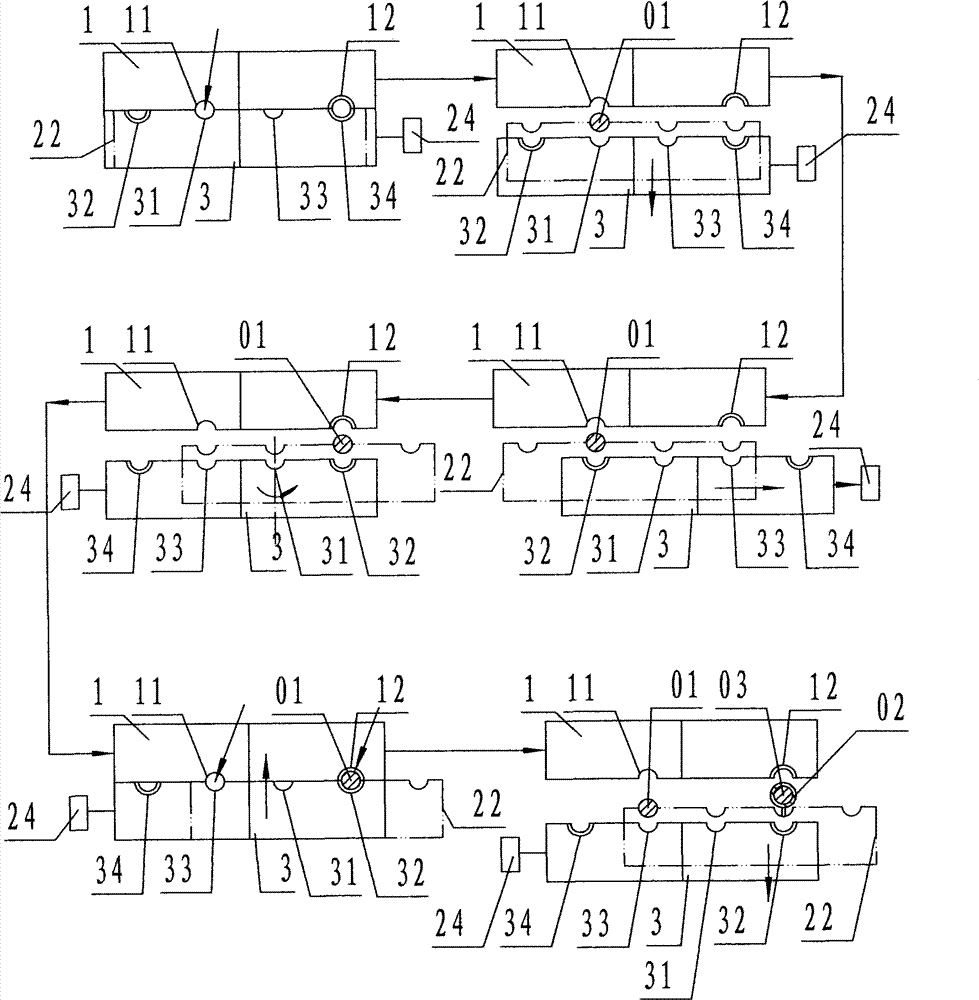

[0024] Refer to Figure 1 ~ Figure 3 , The two-color injection mold for forming double-bread rubber products of the present invention includes a fixed mold 1, a movable mold 2, a movable mold carrier 21, a movable mold core 22, a slider carrier 23, an oil cylinder 24, and a movable cavity slider 3. Wherein: the fixed mold 1 is the stationary part of the fixed device on the fixed worktable of the two-color injection molding machine when the mold is used, and the panel of the fixed mold 1 is respectively provided with a skeleton material for injection of rigid skeleton plastic The port 13 and the encapsulating material gate 14 for injecting soft encapsulated plastic, the fixed bone cavity 11 and the fixed package cavity 12 are respectively provided under the carrier plate of the fixed mold 1 through the runner and the skeleton material gate 13 and The encapsulating material gate 14 communicates with each other, the fixed bone cavity 11 is a cavity located in the skeleton part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com