Ratchet wheel mechanism for slide adjusting

A technology of adjusting wheel and ratchet, applied in the field of presses, can solve the problems of difficult combination, large torque and small transmission force, and achieve the effect of solving difficult combination and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be specifically described below in conjunction with the accompanying drawings.

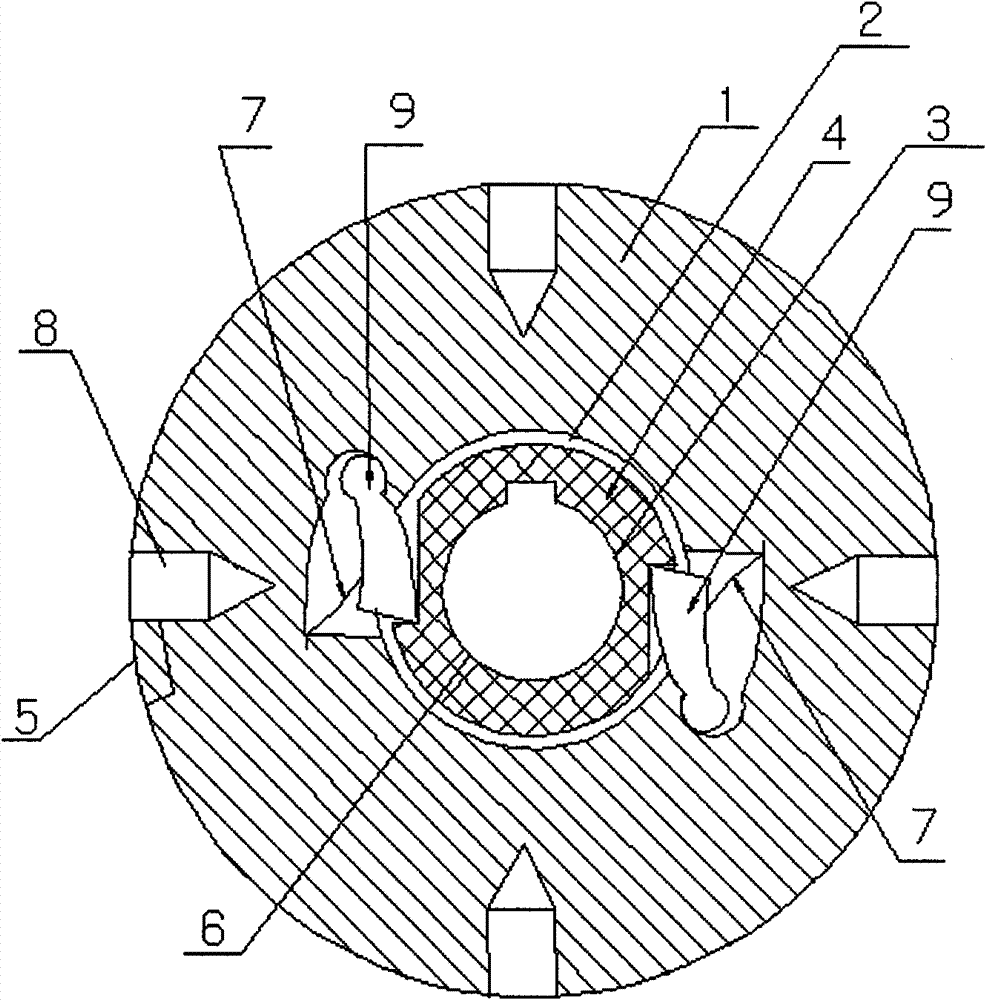

[0009] The mechanism of the ratchet wheel for slider adjustment has a transmission shaft 5. Set the adjustment wheel 1 on the outer circle of the transmission shaft 5. When assembling, pay attention to make the grooves on the inner and outer circles of the two face each other, and install the spring piece 7 on the adjustment wheel. 1 position, and at the same time, install the brake pawl 9 in the groove corresponding to the adjustment wheel 1 and the transmission shaft 5, and install two flat washers 2 from both sides to the inner hole of the adjustment wheel 1 and the outer surface of the transmission shaft 5. On the top of the circle, the bearing 3 should be installed in place during installation. At this time, install the sealing ring 6 in the sealing ring groove of the bearing cover 4, and install and fix the two sides of the bearing cover 4 adjusting wheel 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com