A nylon monofilament constant tension wire feeder

A technology of constant tension and wire feeder, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of large fluctuations in the specifications of nylon forming plain chains, reduce the fluctuations in specifications, and ensure the finished product. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

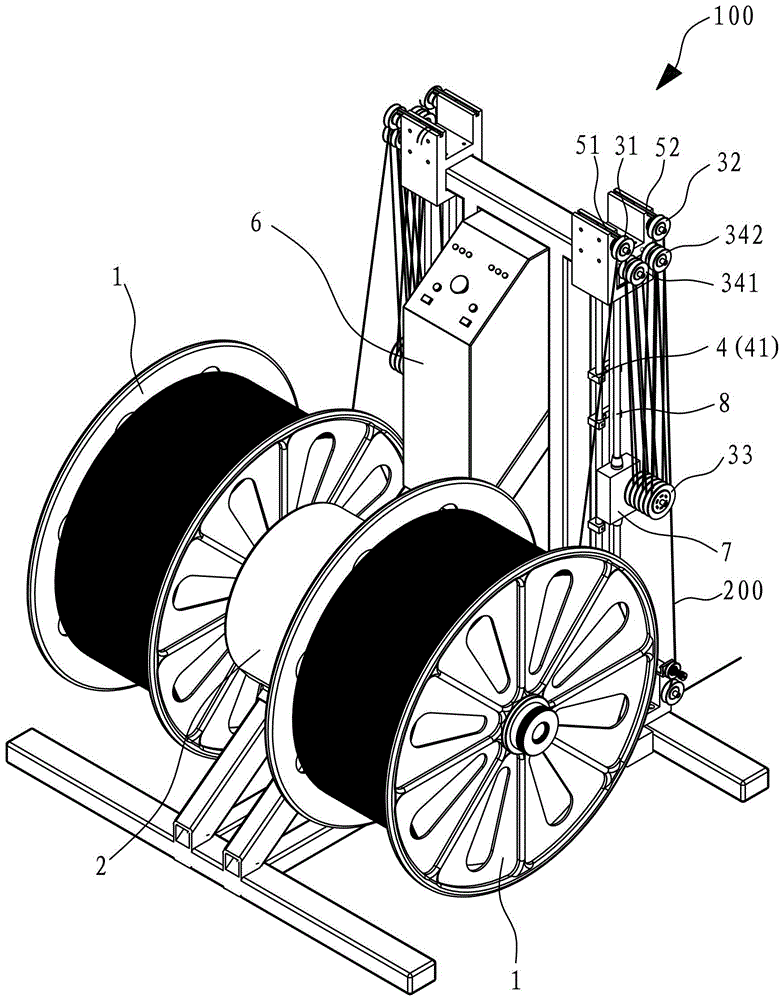

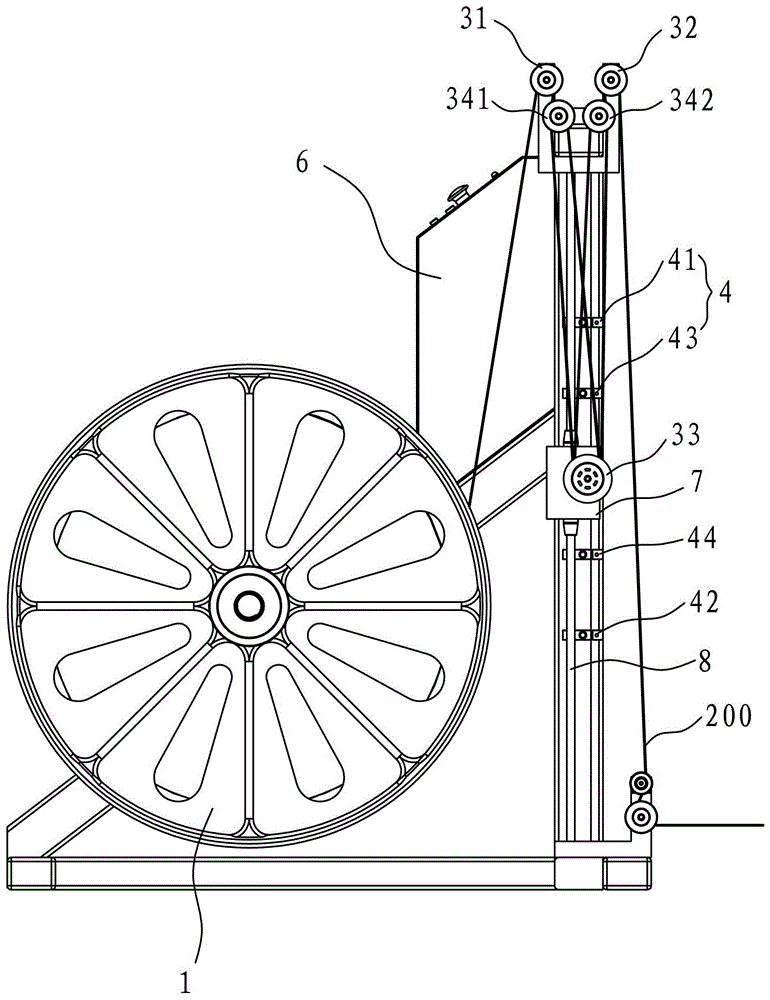

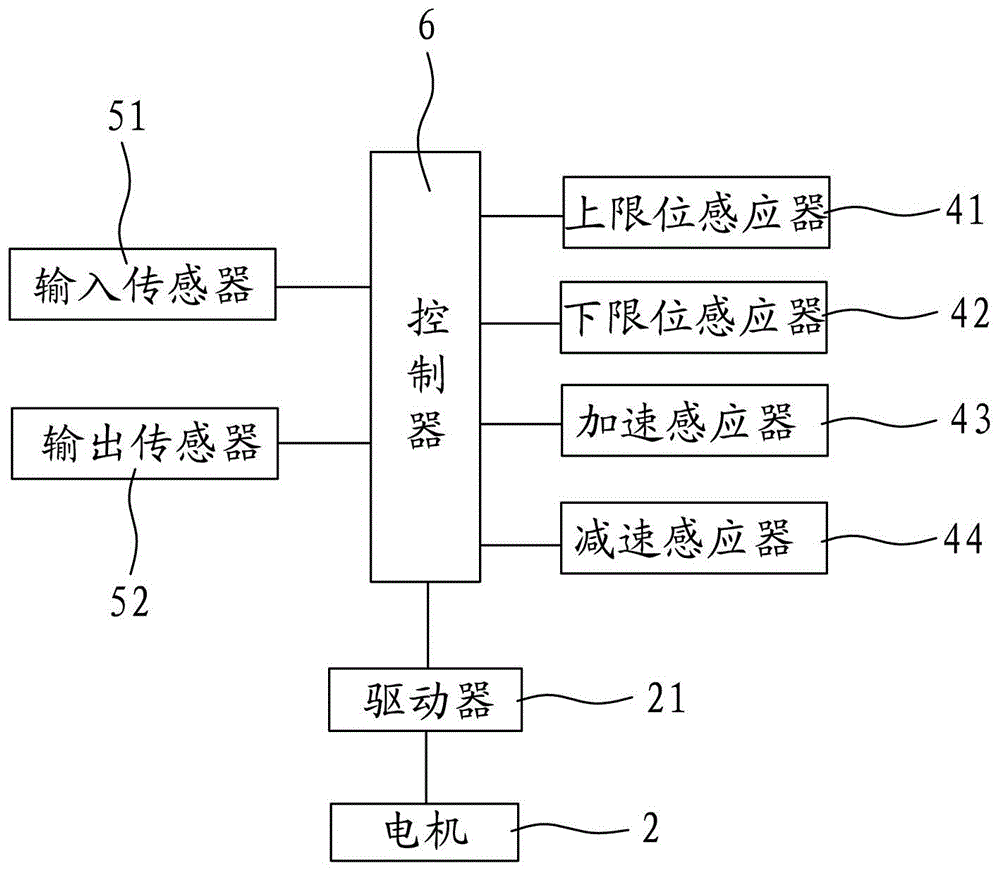

[0029] Such as figure 1 with figure 2 As shown, a nylon monofilament constant tension wire feeder 100 related to the present invention includes: monofilament pan head 1, motor 2, input pulley 31, output pulley 32, counterweight pulley 33, sensor group 4, input sensor 51. Output sensor 52 and controller 6.

[0030] In this embodiment, in order to improve efficiency, the monofilament pan head 1, input pulley 31, output pulley 32, counterweight pulley 33, sensor group 4, input sensor 51, and output sensor 52 are all arranged in two groups. The structure of any of the groups is the same, so only one of them will be described in detail:

[0031] Nylon monofilament 200 is wound around the monofilament pan head 1, and the monofilament pan head 1 is connected to the motor 2 in transmission, thus driven by the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com