A clamping device and a brick holding machine using the same

A clamp and clamp technology, applied in the field of clamp-type finished brick loading and unloading machines, can solve problems such as troublesome operation, and achieve the effect of improving stability and reducing the phenomenon of falling bricks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

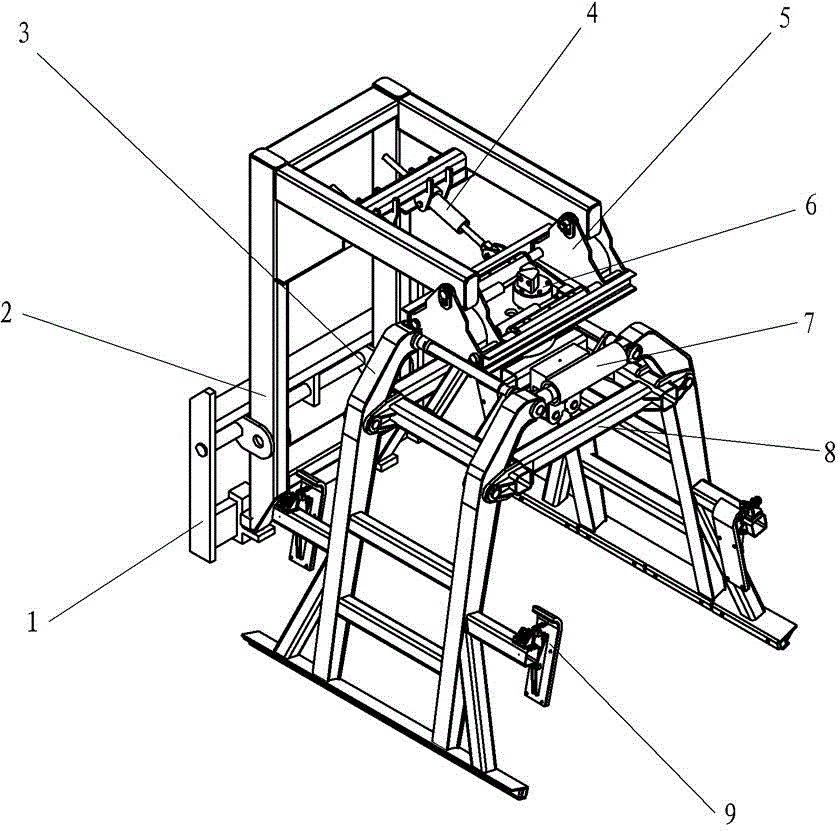

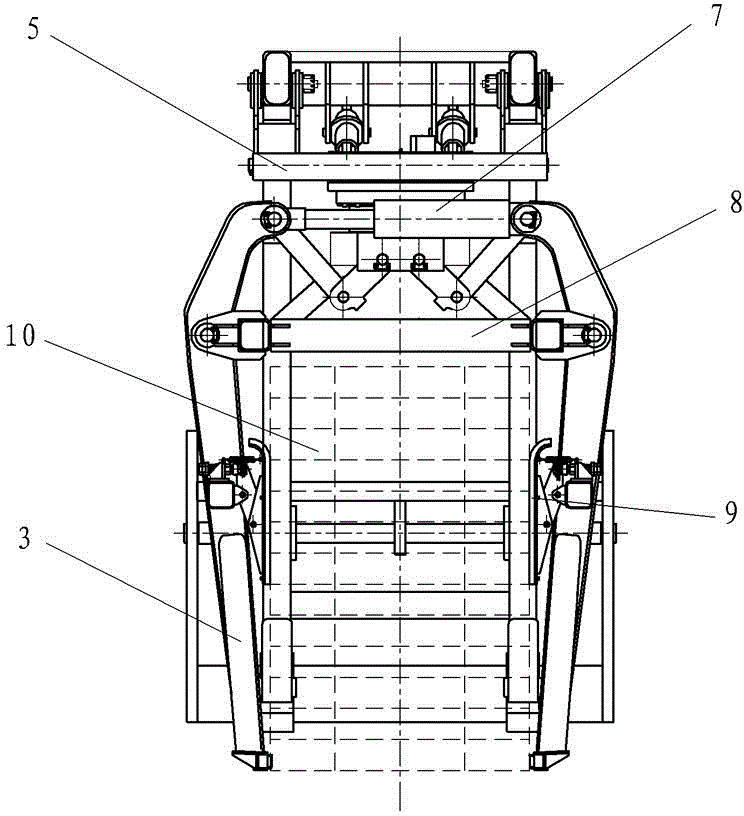

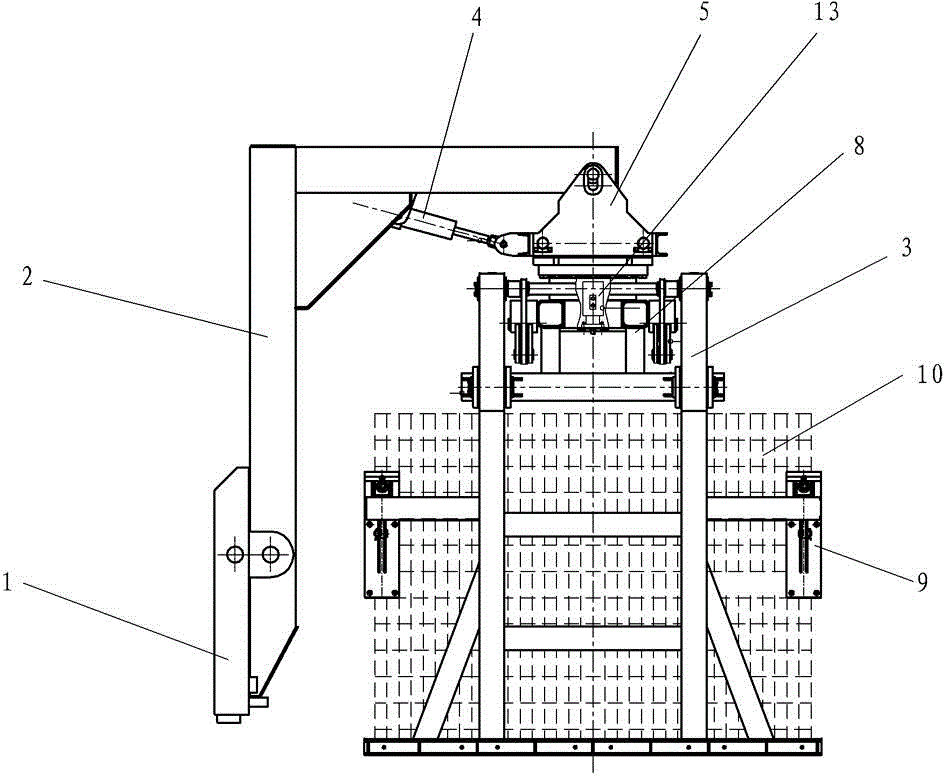

[0031] Embodiments of the clamp device of the present invention: as Figure 1-12 As shown, it includes a hanger 2, a connecting mechanism and a clamp. The hanger 5 of the connecting mechanism adopts a U-shaped frame structure, and the clamp is installed at the bottom of the hanger 5. Installed on the hanger 2, the clamp can swing back and forth with the hanger 5 around two bearing pins, and the above part is the prior art or can be realized by the prior art. The improvement of the present invention is that: the hanger 5 includes a hanger body, the hanger body is a hollow structure, and two slide bars 51 arranged side by side are fixedly connected between the two side parts of the hanger body in the hollow structure, and the slide bar The extending direction of 51 is perpendicular to the swinging direction of hanger 5, slide bar 51 guides and slides along its extending direction and is equipped with slide seat 53, and described fixture is installed on the slide seat 53, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com