Manufacturing method for carbonyl fluoride

A manufacturing method and technology of carbonyl fluoride, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as high toxicity of raw materials, explosion, and difficult reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

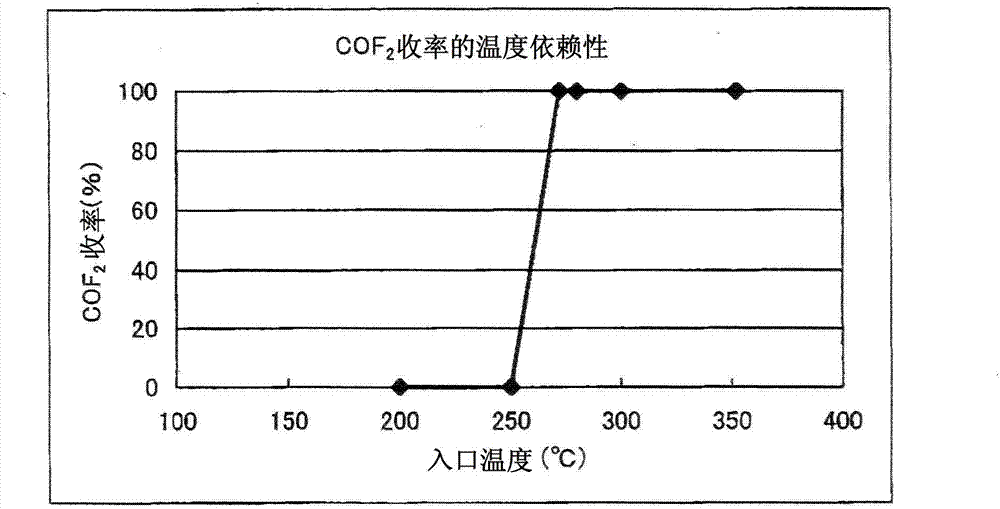

Examples

Embodiment

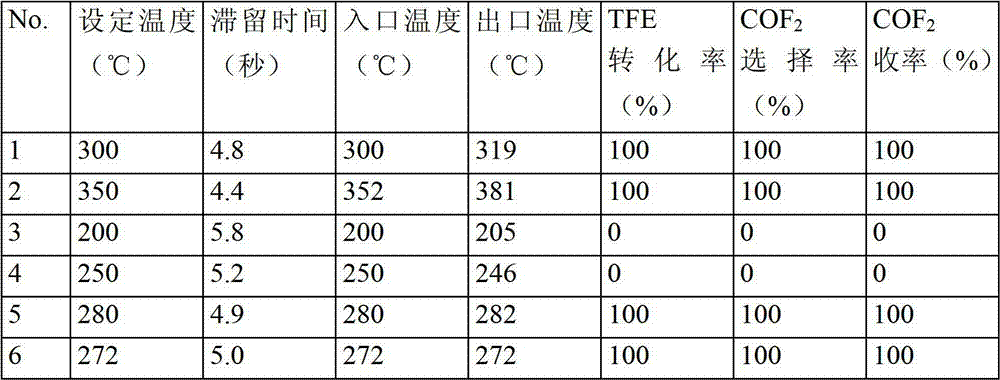

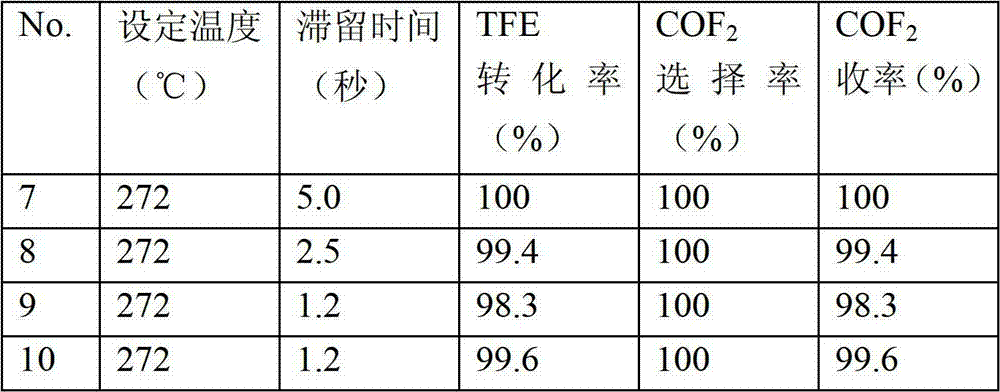

[0046] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited to these examples.

[0047] Tetrafluoroethylene gas (hereinafter also referred to as TFE gas) having a tetrafluoroethylene purity of 99 mol % and a chlorodifluoromethane content of 0.1 mol % or less (substantially 0 mol %) was used as the raw material tetrafluoroethylene gas.

[0048]As the reactor, a straight tube reactor with an inner diameter of 1.78 mm and a length of 20 m (manufactured by Toray Engineering Co., Ltd., "microreactor for high-temperature reaction") whose temperature can be adjusted by an external heater was used.

[0049] The reactor was set to a predetermined temperature in advance, and nitrogen gas was circulated from the inlet at one end of the reactor to the outlet at the other end to clean the inside of the reactor.

[0050] The TFE gas and air were mixed with a stirrer installed near the reactor inlet, introduced into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com