Sealing mechanism of back door and bin body of trash bin

A technology of sealing mechanism and garbage bin, which is applied in the direction of garbage receptacle, sealing device, transportation and packaging, etc. It can solve the problems of inconvenient disassembly, low maintenance and operation efficiency, and troubles for staff, and achieves simple structure, convenient and fast assembly and disassembly maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

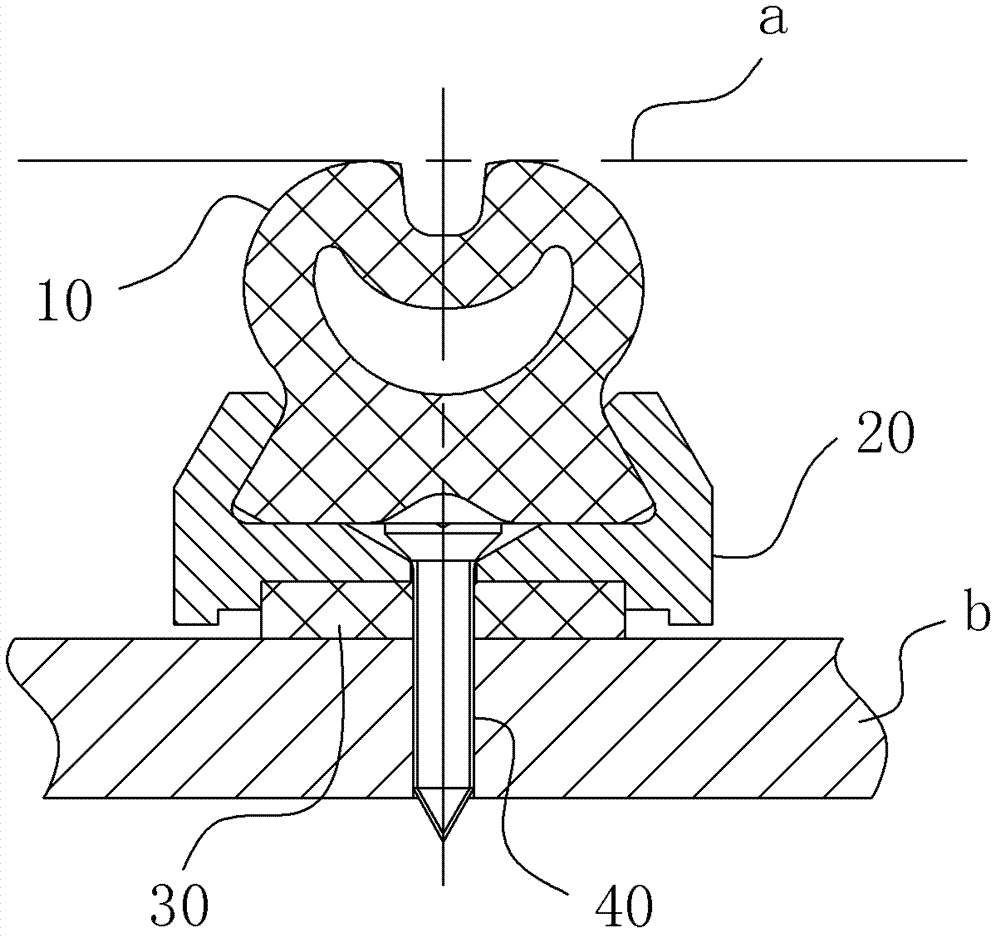

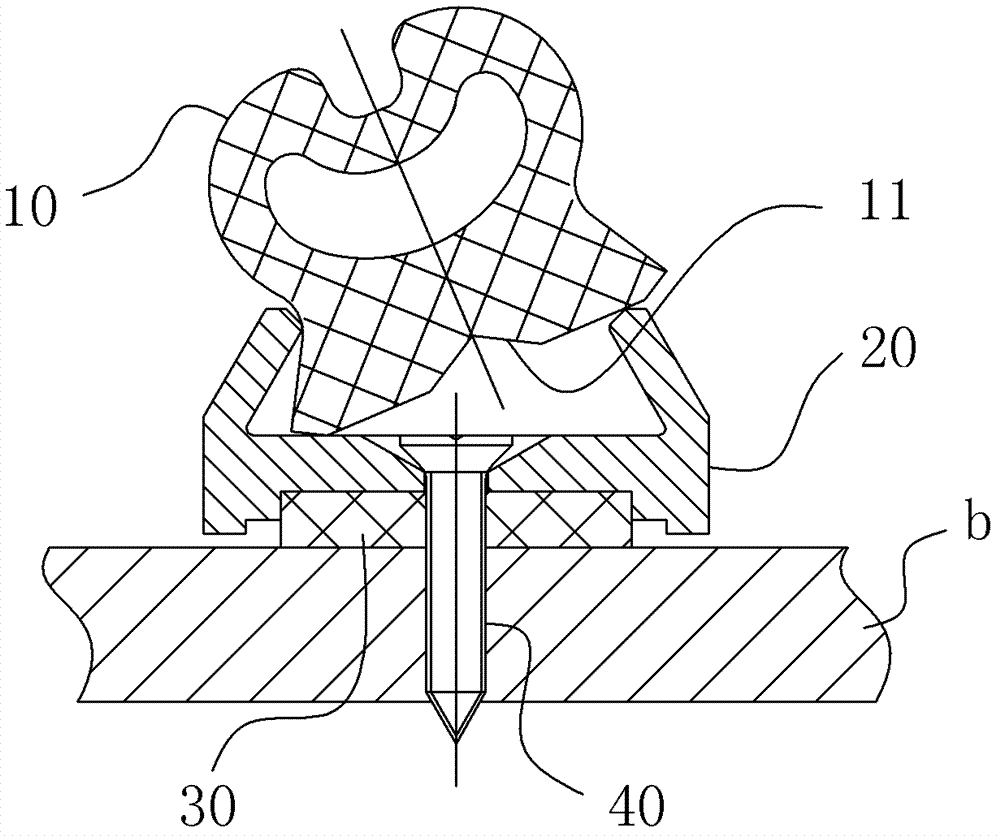

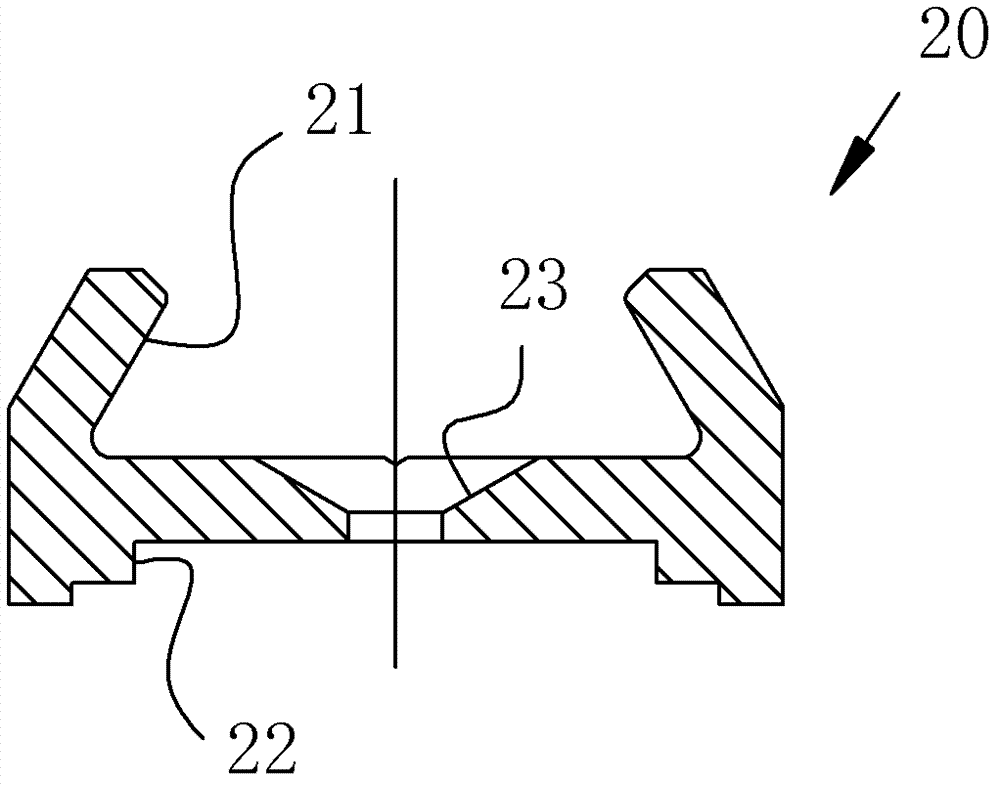

[0010] A sealing mechanism between the back door of a dustbin and the box body, including a sealing strip 10, and the sealing mechanism also includes a base 20 for connecting the sealing strip 10 and the box body b, and the bottom surface of the base 20 and the corresponding mating surface of the box body b Form a surface-fitting and sealed state, the upper part of the base 20 forms a matching part 21 for snap-fitting with the lower part of the sealing strip 10, and the upper part of the base 20 and the sealing strip 10 and / or between the lower part of the base 20 and the box b form a detachable cooperate, such as Figure 1-2 shown.

[0011] As a further preferred solution of the present invention: the mating part 21 is in the shape of a groove with a large mouth, a large bottom, and a small bottom arranged in the direction of the groove length parallel to the length direction of the base 20, and the lower part of the sealing strip 10 is correspondingly in the shape of a protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com