Speed-changing gear device

A speed change device and gear technology, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of box deformation, uneven meshing of gear teeth, uneven transmission, etc., to reduce size and weight, Optimizing the bearing mode and good transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

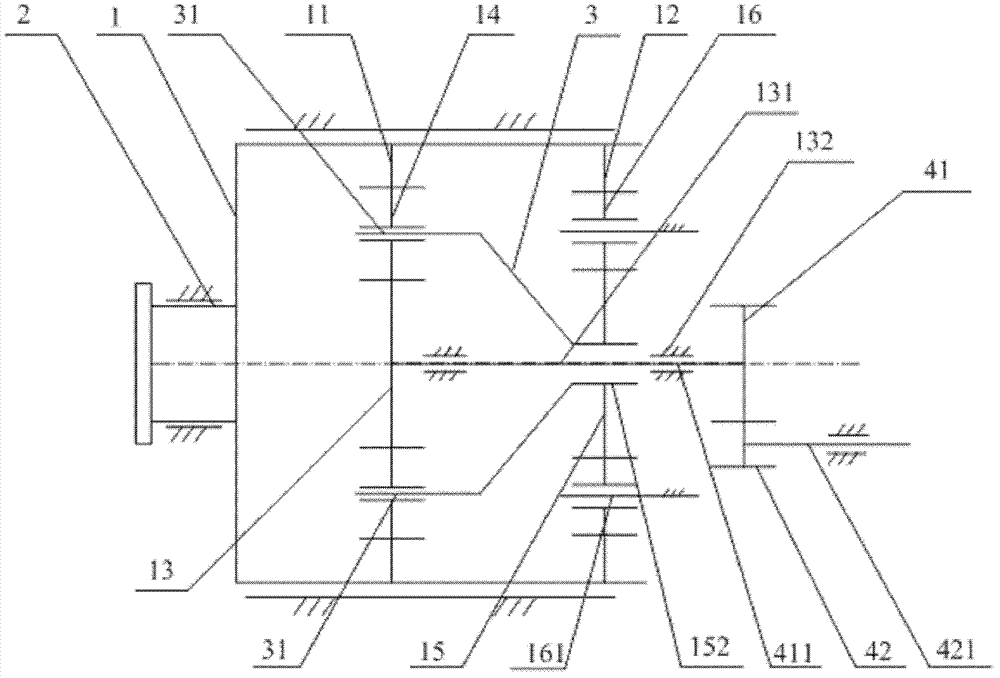

[0016] figure 1 It is the transmission schematic diagram of the gear transmission embodiment of the present invention. Please refer to figure 1 The gear transmission device provided in this embodiment includes: a barrel-shaped transmission sleeve 1 arranged in the horizontal direction, an input shaft 2 is fixedly arranged at the center of the outer side of the bottom surface of the transmission sleeve 1, and a support is fixedly arranged at the opening of the transmission sleeve 1 Cover plate; the inner surface of the transmission sleeve 1 is fixedly provided with a first-stage internal ring gear 11 and a second-stage internal ring gear 12, the first-stage internal ring gear 11 meshes with the first-stage sun gear 13 through at least one first-stage planetary gear 14, and the second-stage internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com