Testing device and method of winch

A test device and winch technology, which is applied in the field of winch manufacturing, can solve the problems of inconvenient replacement of external loads and inconvenient tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

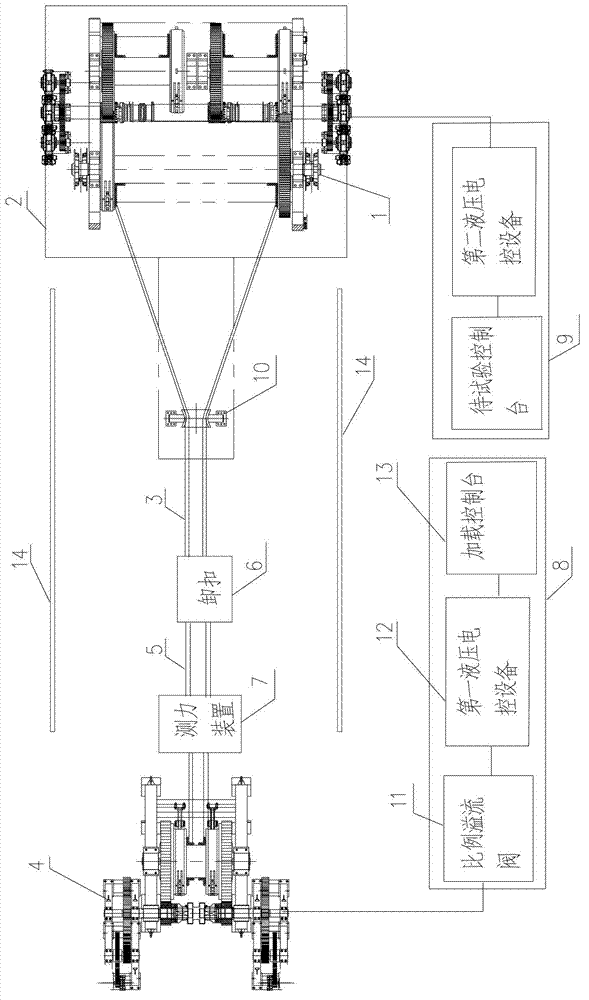

[0027] The embodiment of the present invention provides a kind of winch test device, see figure 1 , the device comprises: a base plate 2 for installing the winch 1 to be tested, a first cable 3 for being connected to the winch 1 to be tested, a loading winch 4, a second cable 5 connected to the loading winch 4, and a shackle 6 , the force measuring device 7 for measuring the tension that the second cable 5 is subjected to, the loading winch control system 8 for controlling the loading winch 4 and the winch control system 9 for controlling the winch 1 to be tested; the first cable 3 passes The shackle 6 is connected to the second cable 5 . The loading winch 4 is electrically connected to the loading winch control system 8 , and the test winch 1 is electrically connected to the test winch control system 9 .

[0028] Among them, various performance parameters of the loading winch 4 have been calibrated, and the load capacity can be 125 tons to 500 tons.

[0029] Preferably, the...

Embodiment 2

[0037] The embodiment of the present invention provides a kind of winch test method, this method comprises:

[0038] Set the loading winch to the cable receiving state, and adjust the output of the loading winch through the loading winch control system, so that the tension on the second cable corresponds to the different load values of the winch to be tested, and carry out load and overload tests on the winch to be tested. This test method uses the loading winch as the external load, and completes the load and overload tests without replacement.

[0039] Wherein, the drum of the winch to be tested is wound with a specified number of layers of the first cable, and its end passes through the fairlead and is firmly connected with the second cable on the loading winch through a shackle.

[0040] In specific implementation, the above-mentioned different load values can be selected according to the test requirements and actual conditions, for example: during the load test: the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com