Comparison test block for creeping wave fault detection

A technology for comparing test blocks and creeping waves, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves, and can solve problems such as the lack of effective methods to determine the equivalent of defect reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

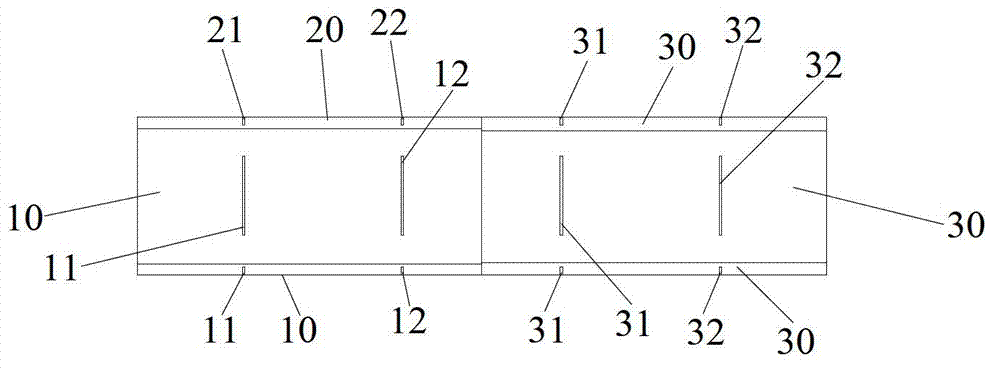

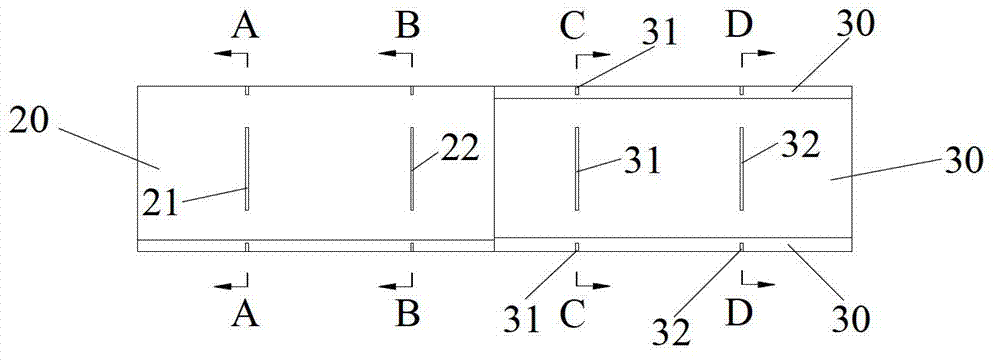

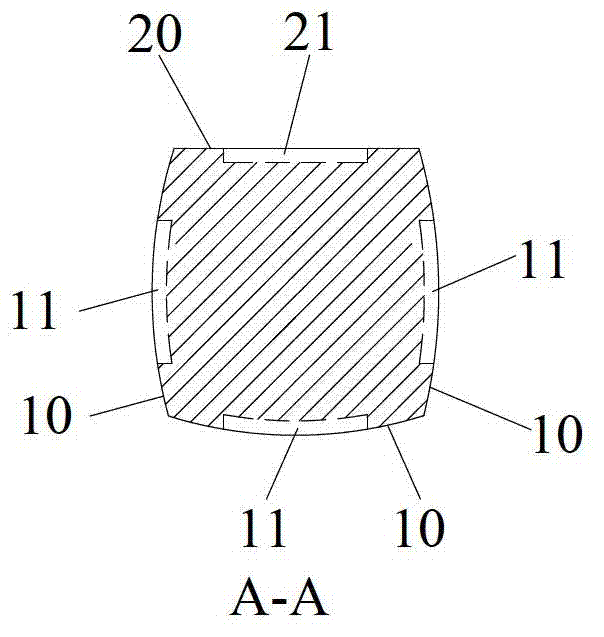

[0035] Such as Figures 1 to 6 As shown, the present invention provides a comparison test block for creeping wave flaw detection, wherein the comparison test block has a columnar structure, and one end of the comparison test block is provided with at least one first detection surface 10, the first detection The surface 10 is a part of the cylindrical surface and protrudes outward, the direction of the generatrix of the first detection surface 10 is consistent with the length direction of the comparison test block, and the first detection surface 10 is provided with a first detection groove 11, the first detection surface 10 The groove 11 is a groove of equal de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com