Intensive connector

A connector and intensive technology, which is applied in the direction of connection, parts of connection devices, fixed/insulated contact components, etc., can solve problems such as errors, inconvenient inventory, and high production costs, so as to reduce the quantity, improve the current-carrying effect, The effect of low error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention are described in detail below:

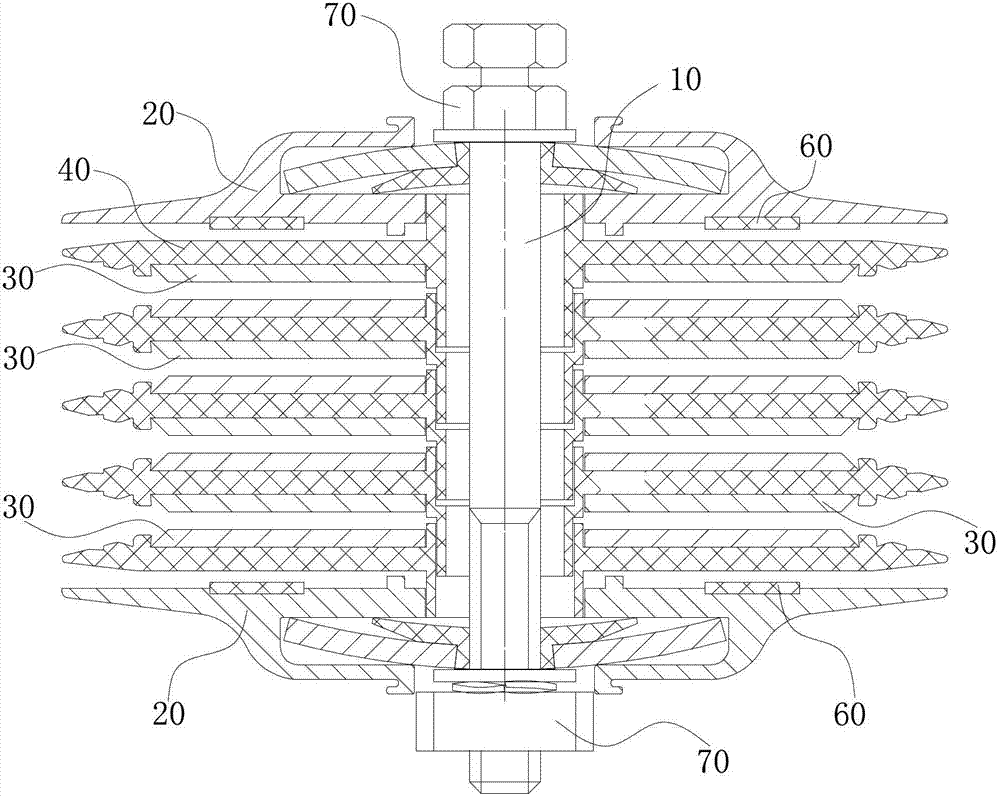

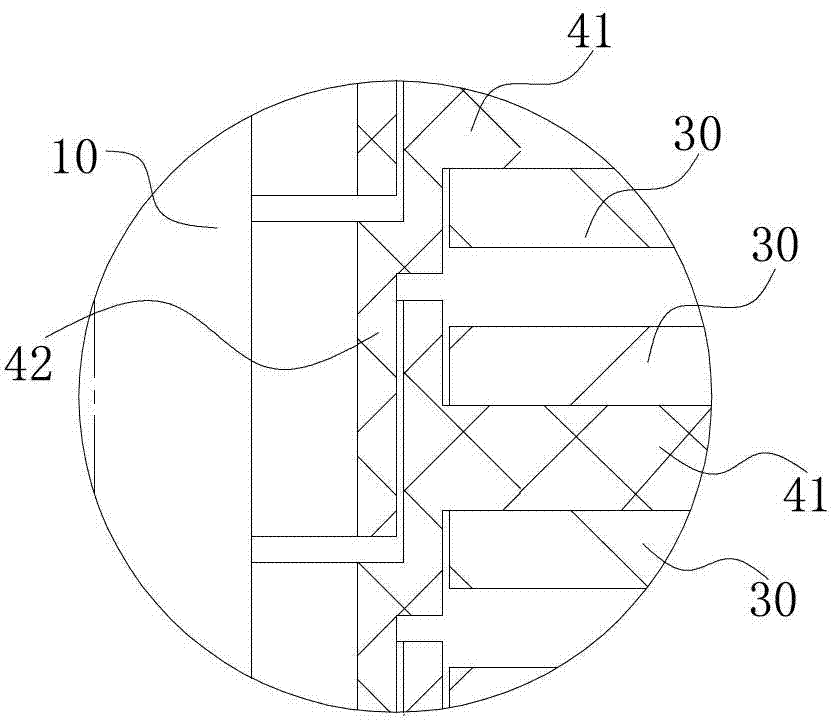

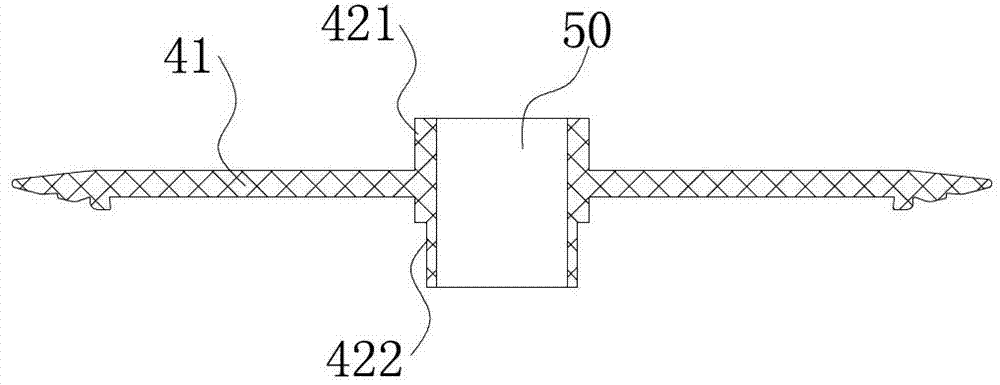

[0039] Such as Figure 1 to Figure 8 As shown, a dense connector includes: bolts 10, two pressure plates 20, a plurality of connecting pieces 30 and a plurality of insulating partitions 40, and the pressing plates 20, connecting pieces 30 and insulating partitions 40 are all provided with sleeve holes 50, two pressure plates 20, multiple connecting pieces 30 and multiple insulating partitions 40 are all set on the bolt 10 through the sleeve hole 50, and the connecting piece 30 is located between two adjacent insulating partitions 40, the two bolts 10 The end is connected with a nut 70, and the connecting piece 30 and the insulating partition 40 are pressed tightly by two pressing plates 20; the insulating partition 40 includes a plate body 41 and a shaft sleeve body 42, and the shaft sleeve body 42 is set on the sleeve through the sleeve hole 50. Bolts 10 , and the bushing bodies 42 of two adjacent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com