Combination joint and production method thereof

A technology of connecting tubes together, applied in other medical devices, etc., can solve problems such as difficulty in controlling the amount of cyclohexanone dipped, operator injury, patient injury, etc., to ensure product quality uniformity, firm and reliable sealing, and provide The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order for those skilled in the art to better understand the technical solution of the present invention, the following specific examples are provided. However, these examples do not limit the protection scope of the present invention.

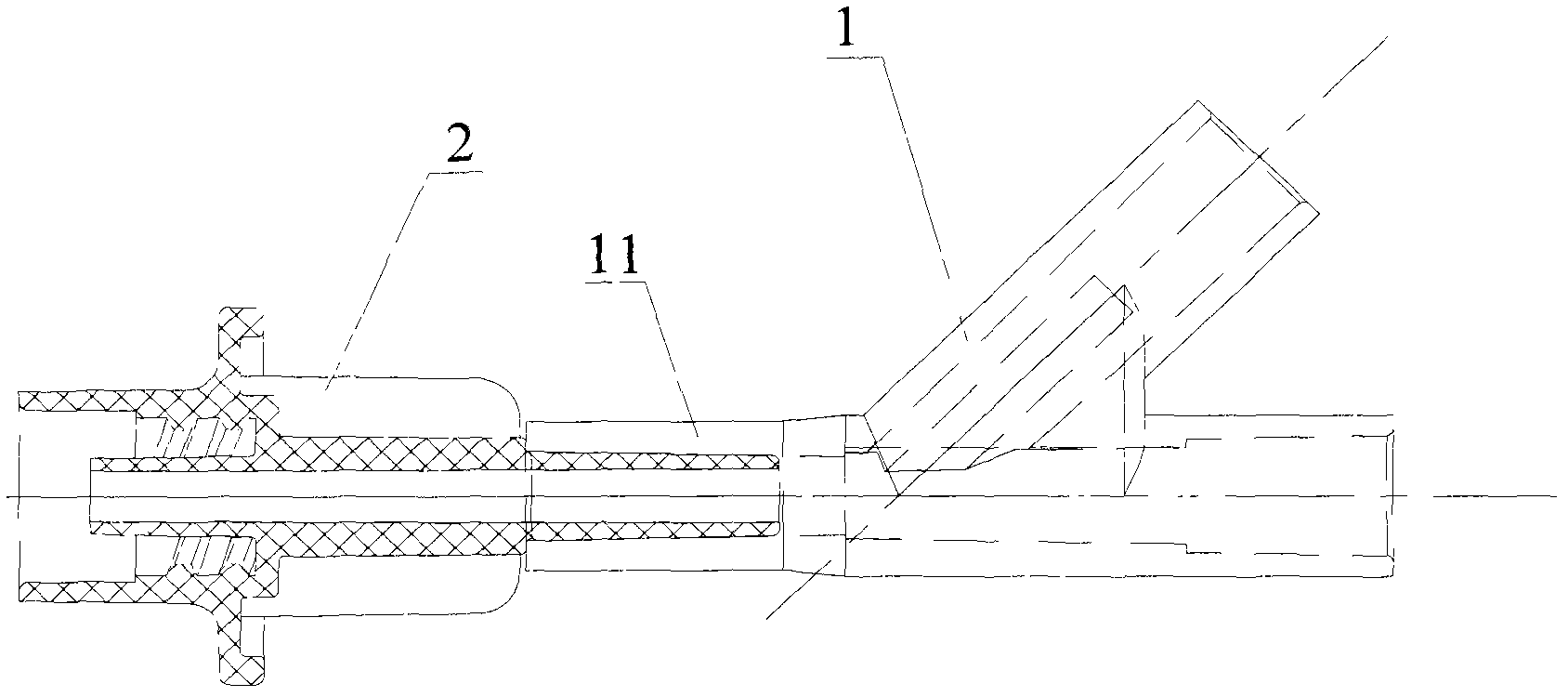

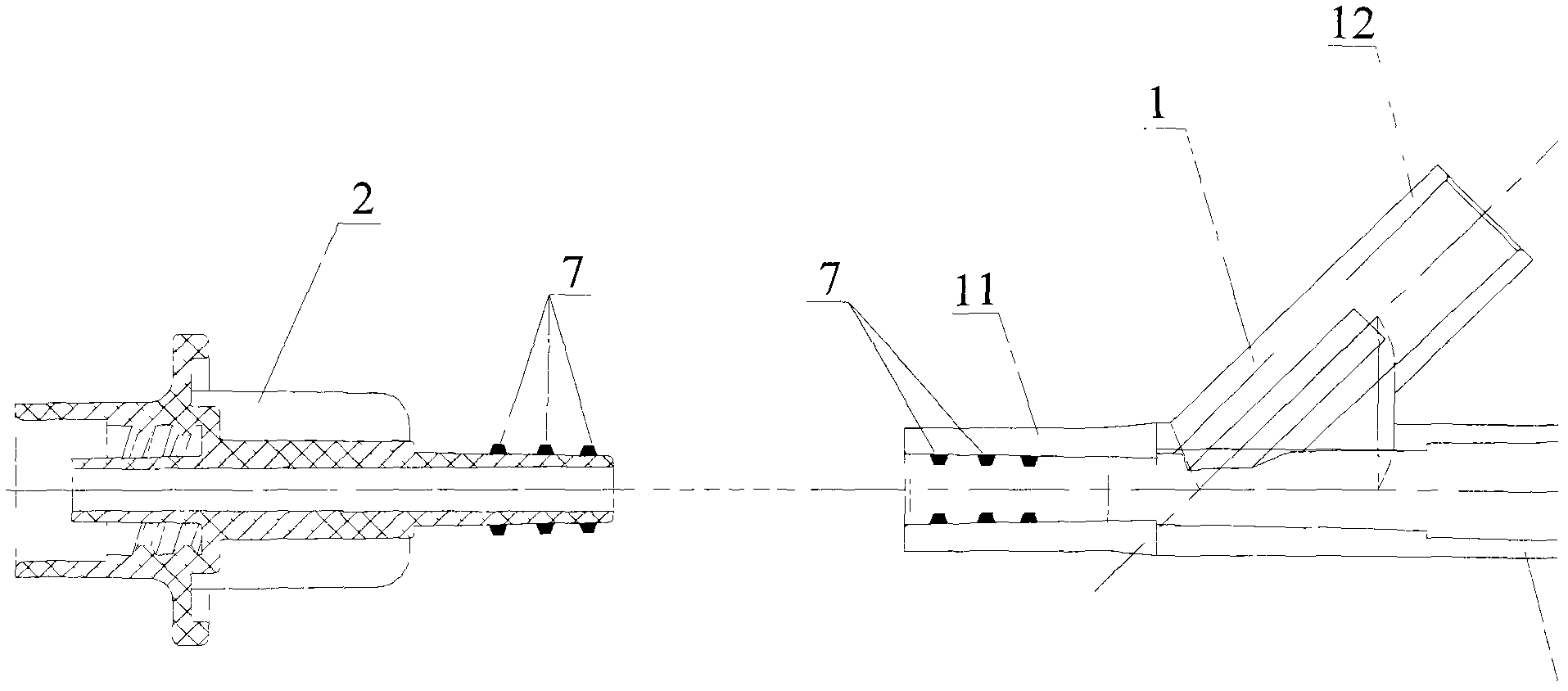

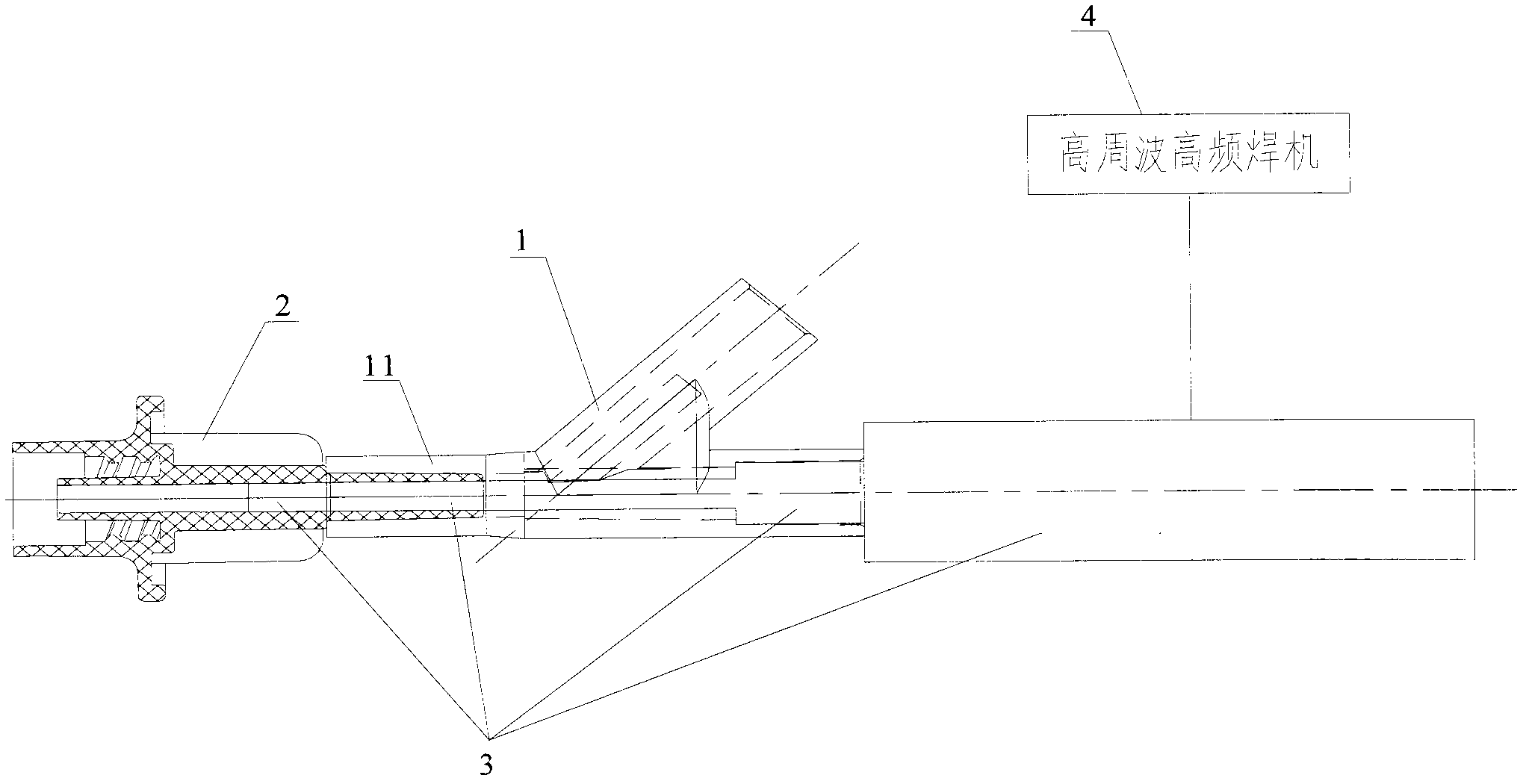

[0040] Such as figure 1 Shown is a specific embodiment of the combination joint of the present invention. In this embodiment, the combined joint includes a three-way pipe 1 and a connecting pipe 2. A nozzle 11 of the three-way pipe 1 is connected to the connecting pipe 2. Specifically, a nozzle 11 of the three-way pipe 1 is connected to the connecting pipe. 2 Solder connections.

[0041] The combination joint provided by the present invention includes a tee pipe 1 and a connecting pipe 2 , and a nozzle 11 of the tee pipe 1 is welded to the connecting pipe 2 . In this way, when manufacturing the combined joint, it is not necessary to manually dip the cyclohexanone, and use cyclohexanone to connect a nozzle 11 of the tee pipe 1 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com