Lifting support plate bracket for receiving material of steel plate shearer

A pallet rack and shearing machine technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of high cost, low control precision, and cumbersome control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

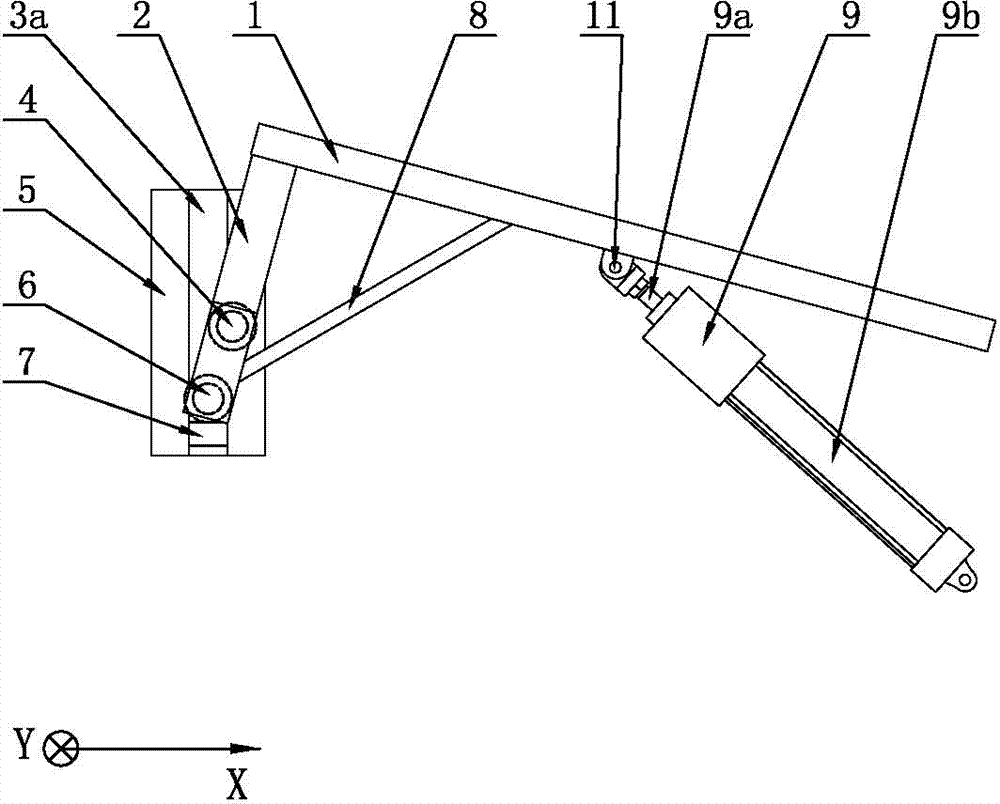

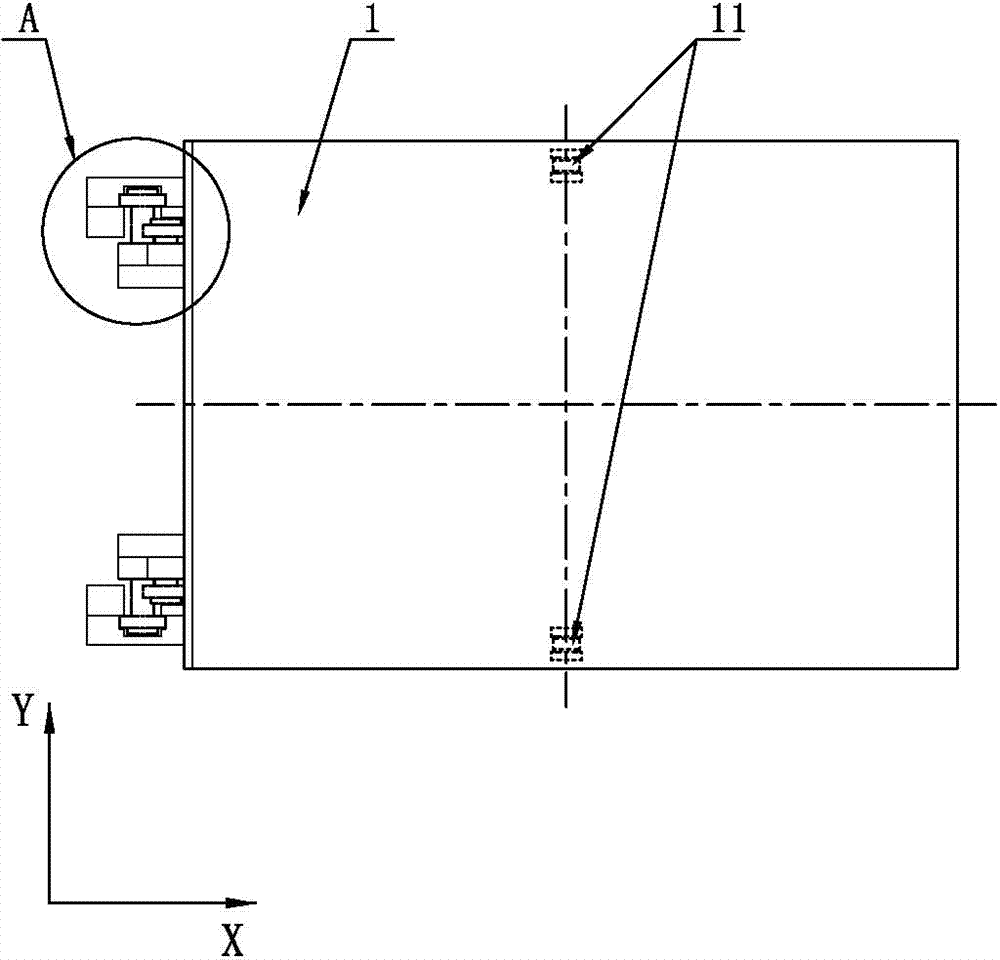

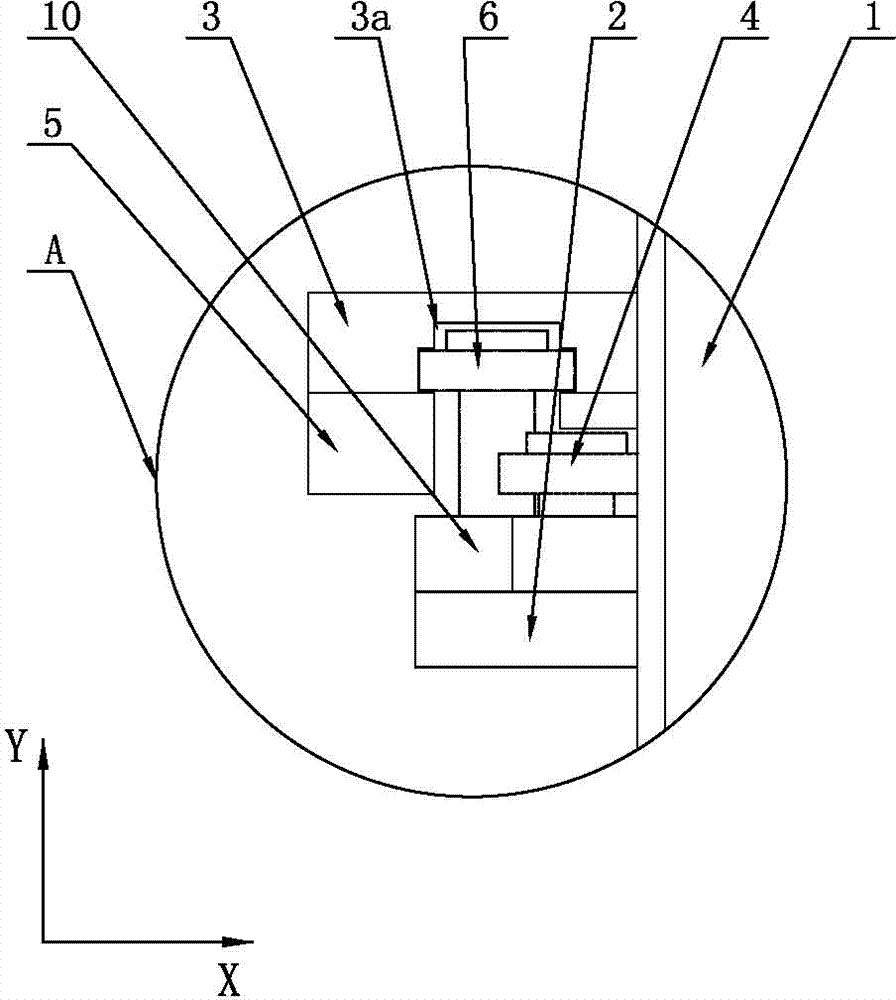

[0015] Such as Figure 1-3 The shown one kind of plate shearing machine receiving and lifting pallet frame includes two guide rods 2 fixedly installed on the pallet 1, connecting ribs 8 are fixed between the pallet 1 and the guide rod 2, and the guide rod 2 passes through the guide bearing 6 Slidingly set in the guide groove 3a on the guide seat 3, the guide seat 3 is installed on the base, the limit block 7 is arranged at the bottom of the guide groove 3a, the limit baffle plate 5 is also arranged on the guide seat 3, and the guide rod 2 is also provided with There is a limit bearing 4 matched with the limit baffle 5, the guide bearing 6 and the limit bearing 4 are all fixedly installed on the guide rod 2 through the connecting block 10, and the bottom of the supporting plate 1 is hinged with two cylinder piston rods 9a, the cylinder 9 and the two hinge points 11 of the pallet 1 are set on the center line of the pallet 1 in the Y direction, and the two hinge points 11 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com