Battery exchange mechanical arm structure of electric vehicle

An electric vehicle and electromechanical technology, applied in the direction of manipulators, electric power devices, power devices, etc., can solve the problems of inability to quickly replace electric vehicle batteries, single performance, low degree of automation and intelligence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

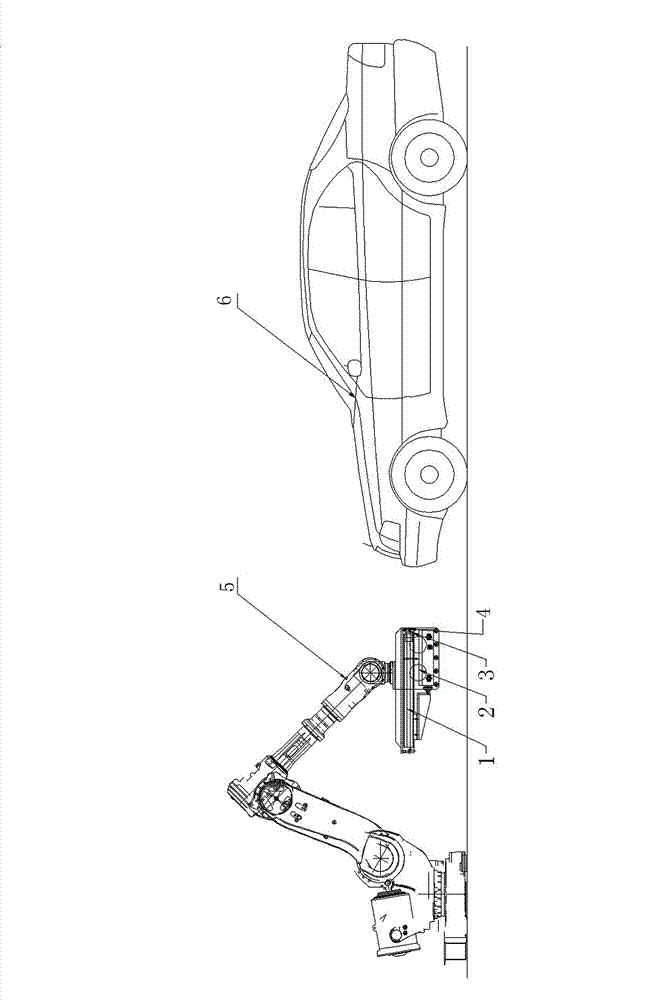

[0008] The present invention will be further described below with reference to the accompanying drawings.

[0009] The present invention is a mechanical arm structure for electric vehicle battery replacement, which includes a robot arm 5, which is different from the prior art in that: the end of the robot arm 1 is provided with a grasping mechanism 1, and the grasping mechanism 1 is respectively provided with There are measurement sensors 3 and vision sensors 4 .

[0010] During specific implementation, the front end of the grasping mechanism 1 is provided with a visual sensor 4 and a measurement sensor 3 .

[0011] During specific implementation, the electric car 6 that needs to be replaced is parked at any position within the working range of the robot; the grasping mechanism of the mechanical arm automatically detects the position of the battery through the measuring sensor and the visual sensor; after the grasping mechanism performs battery grasping, Place it in the autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com