High Speed Roll Die Cutter Die Holder

A technology of cutter die and high-speed roller, which is applied in metal processing and other directions, can solve problems such as unguaranteed precision, easy vibration, and vibration affecting cutting, etc., to achieve the effect of improving the use effect, eliminating the possibility of vibration, and improving the use condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

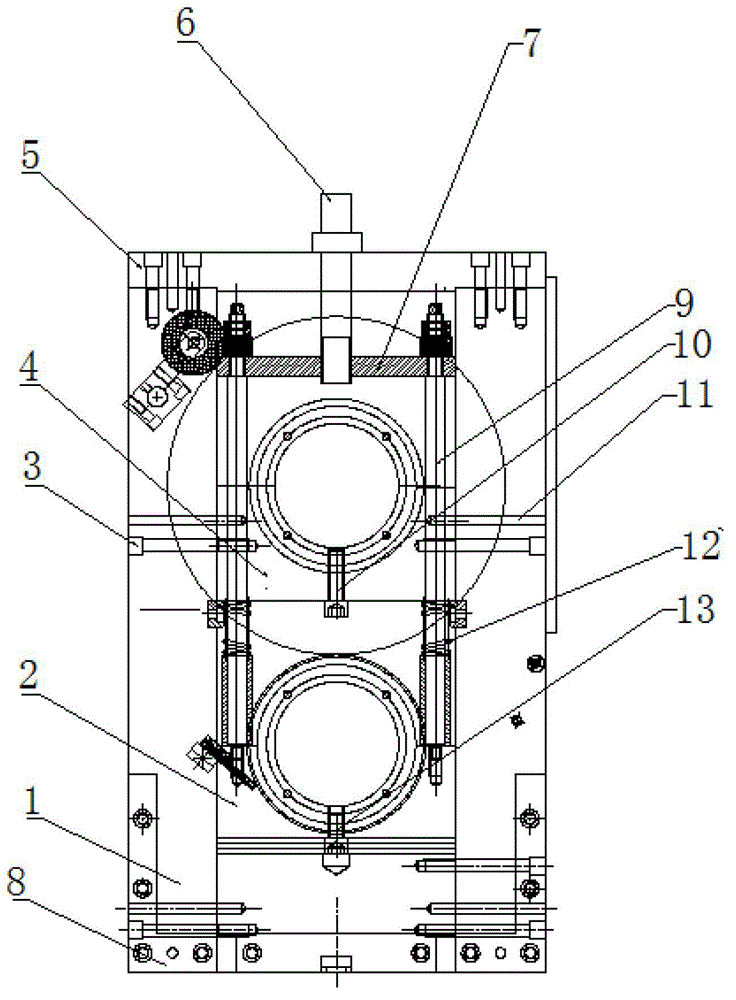

[0030] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

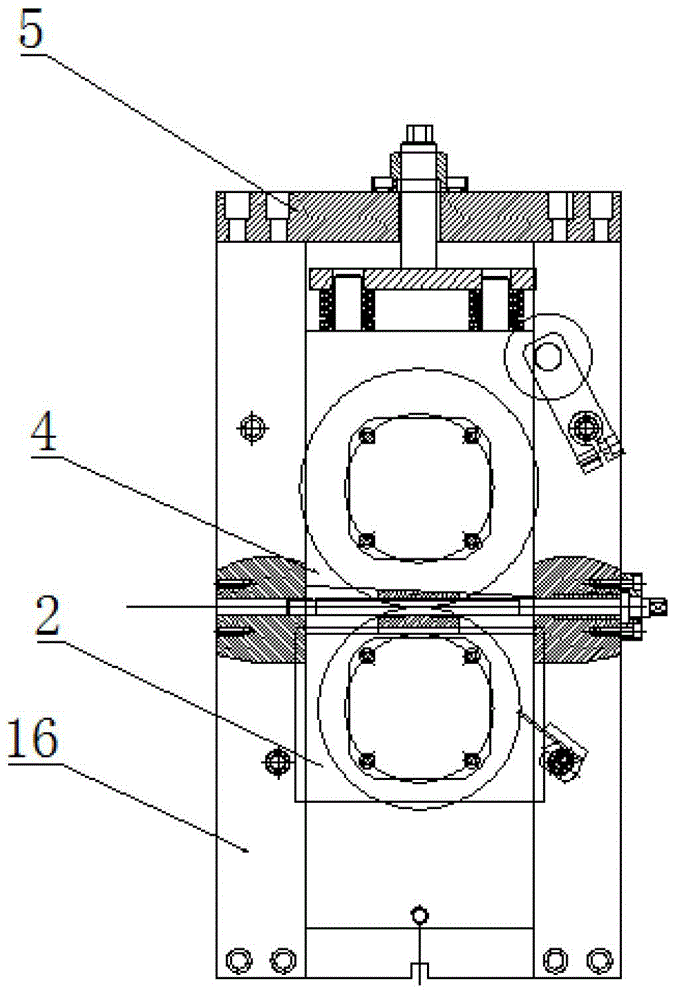

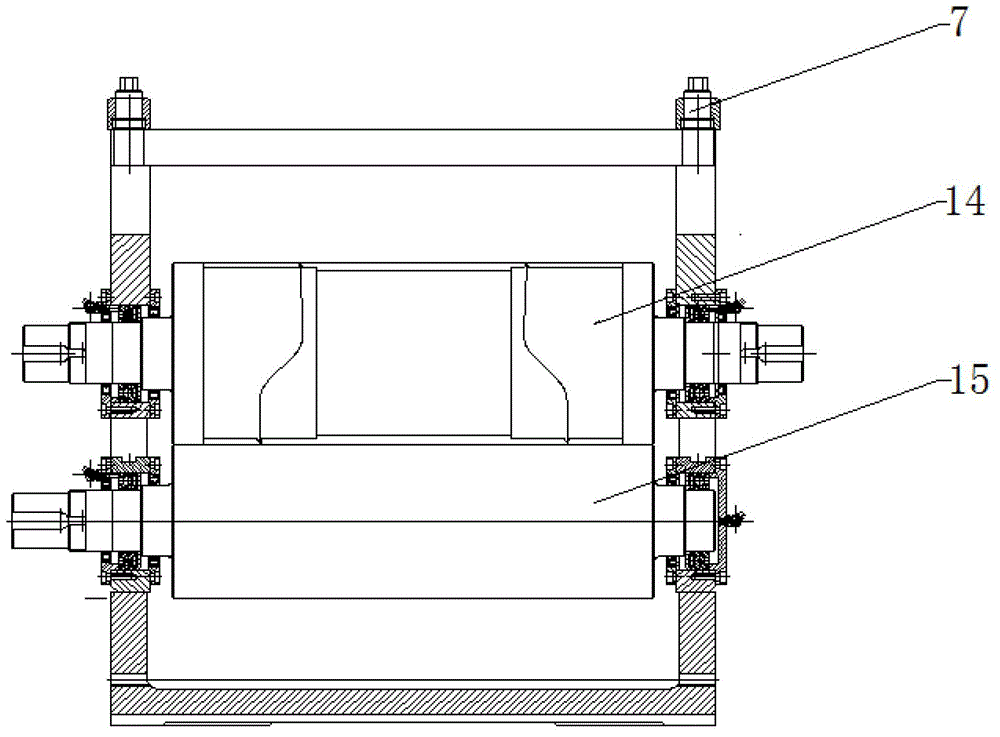

[0031] see Figure 2-7 , a kind of high-speed rolling die-cutter mold frame that the present invention provides as shown in the accompanying drawing, comprises frame structure, two upper bearing seats 4, two lower bearing seats 2, upper main cutter roller 14, lower anvil roller 15 and pressurized mechanism, the frame structure is composed of two side plates 1, a top plate 5 and a base 8, the two side plates 1 are correspondingly provided with longitudinal chute, the two upper bearing seats 4 are correspondingly fixed on the two side plates 1, and the lower bearing The seat 2 is arranged on the side plate 1 and can slide along the chute under the drive of the pressing mechanism. The upper main cutter roller 14 is rotatably arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com