CSC three-layer composite spunlaced nonwoven and method for producing same

A non-woven fabric and layer compounding technology, applied in the direction of layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of poor dirt holding capacity, insufficient bulkiness, easy deformation, etc., and achieve soft hand feeling, Good vacuuming effect, full and fluffy feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The production method for preparing the above-mentioned CSC three-layer composite spunlaced nonwoven fabric includes opening and cleaning polyester fibers, carding into a web, spunlace composite molding of the upper layer, the middle layer and the lower layer, and drying, and is characterized in that:

[0018] In the step of polyester fiber opening and cleaning, the distance between the stripping roller of the bale opener and the stripper is 5 mm, and the speed of the main cylinder of the carding machine is 800rpm, the speed of the chest cylinder is 400rpm, and the upper and lower messy rollers The speed is 950rpm,

[0019] In the spunlace composite molding step, the pressure of the pre-wet spunlace head on the spunlace mesh curtain is 20bar, the pressure of the normal spunlace head is 30bar, and the counterpuncture pressures of the two spunlace heads of the second drum are 30bar and 30bar respectively. 35bar, the three hydroentanglement pressures of the third drum are ...

Embodiment 2

[0022] In the polyester fiber opening and cleaning step, the distance between the stripping roller of the bale opener and the stripper is 6 mm, and the speed of the main cylinder of the carding machine is 1150rpm, the speed of the chest cylinder is 620rpm, and the upper and lower messy rollers The speed is 1100rpm,

[0023] In the spunlace composite molding step, the pressure of the pre-wet spunlace head on the spunlace mesh curtain is 35bar, the pressure of the normal spunlace head is 45bar, and the counterpuncture pressures of the two spunlace heads of the second drum are 45bar and 45bar respectively. 55bar, and the three hydroentanglement pressures of the third drum are 60bar, 75bar and 65bar respectively;

[0024] In the spunlace composite molding step, the efficiency of the three negative pressure suction fans on the spunlace machine is 75%, 85%, and 75% respectively, and the efficiency of the three circulation fans and the exhaust fan in the oven is 72%. is 105°C.

Embodiment 3

[0026] In the polyester fiber opening and cleaning step, the distance between the stripping roller of the bale opener and the stripper is 8 mm, and the speed of the main cylinder of the carding machine is 1350rpm, the speed of the chest cylinder is 850rpm, and the upper and lower messy rollers The speed is 1300rpm,

[0027] In the spunlace compound forming step, the pressure of the pre-wet spunlace head on the spunlace mesh curtain is 50 bar, the pressure of the forward spunlace head is 60 bar, and the pressure of the two spunlace heads of the second drum is 60 bar and 80 bar respectively , the three hydroentanglement pressures of the third drum are 85bar, 100bar and 95bar respectively;

[0028] In the spunlace composite molding step, the efficiency of the three negative pressure suction fans on the spunlace machine is 85%, 95%, and 80% respectively, and the efficiency of the three circulation fans and the exhaust fan in the oven are all 85%. It is 115°C.

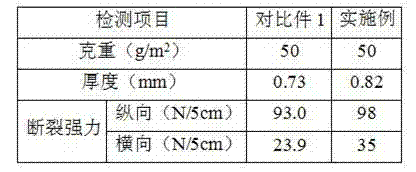

[0029] The compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com