Germanium-tin co-doped monocrystalline silicon for solar cell and method for preparing same

A technology for solar cells and single crystal silicon, which is applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of high production cost and low conversion efficiency of monocrystalline silicon solar cells, and achieves low production cost, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

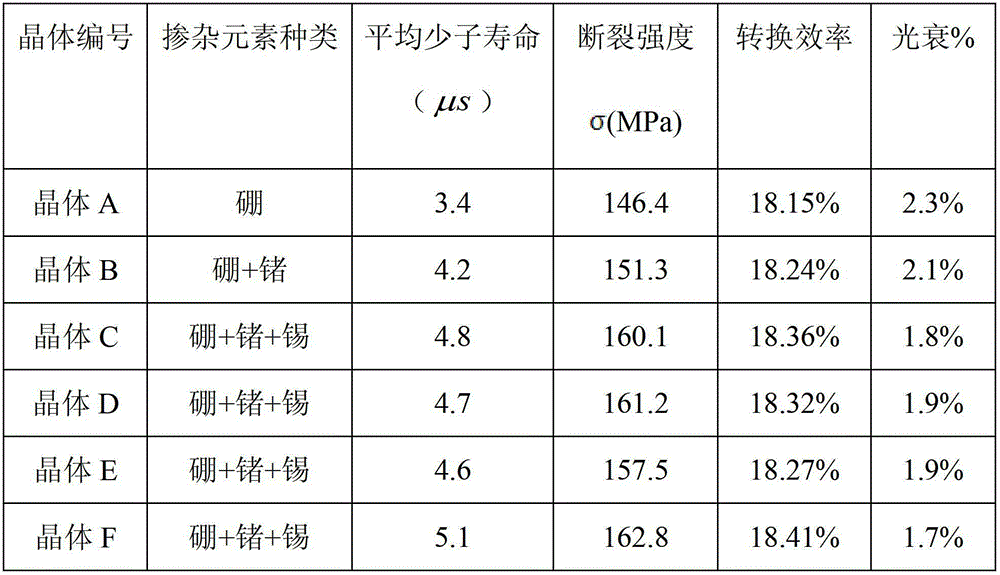

[0019] Select single crystal silicon rods A, B, C, D, E and F, wherein single crystal silicon rods C, D, E and F are single crystal silicon rods of the present invention, and the impurity concentration of each crystal rod is as follows:

[0020] Monocrystalline silicon rod A is P-type monocrystalline silicon obtained by the conventional CZ method, and the boron concentration is 60ppbw;

[0021] Single crystal silicon rod B is P-type single crystal silicon containing 100ppmw germanium prepared by CZ method, and the boron concentration is 60ppbw;

[0022] Single crystal silicon rod C is P-type single crystal silicon containing 100ppmw germanium and 100ppbw tin prepared by CZ method, and the boron concentration is 60ppbw;

[0023] Single crystal silicon rod D is P-type single crystal silicon containing 200ppmw germanium and 50ppbw tin prepared by CZ method, and the boron concentration is 60ppbw;

[0024] Single crystal silicon rod E is P-type single crystal silicon containing 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com