Method for improving marking quality of QR code on surface of gold-plated part

A two-dimensional code, quality technology, applied in the direction of metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of consistency, easy breakdown coating, insufficient color contrast of laser processing two-dimensional code, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) NiP layer thickness 2.14um, Au layer thickness 0.053um;

[0044] (2) The laser focus spot size on the surface of gold-plated parts is 45.07um;

[0045] (3) The laser spot size before incident is 2.41mm;

[0046] (4) Push the pretreated gold-plated parts to the laser processing station, and press the gold-plated parts; when the laser receives the light signal, the laser processes the gold-plated parts according to the set laser parameters; after the processing is completed, The gold-plated parts are transported to the CCD reading and grading station, and finally enter the storage box.

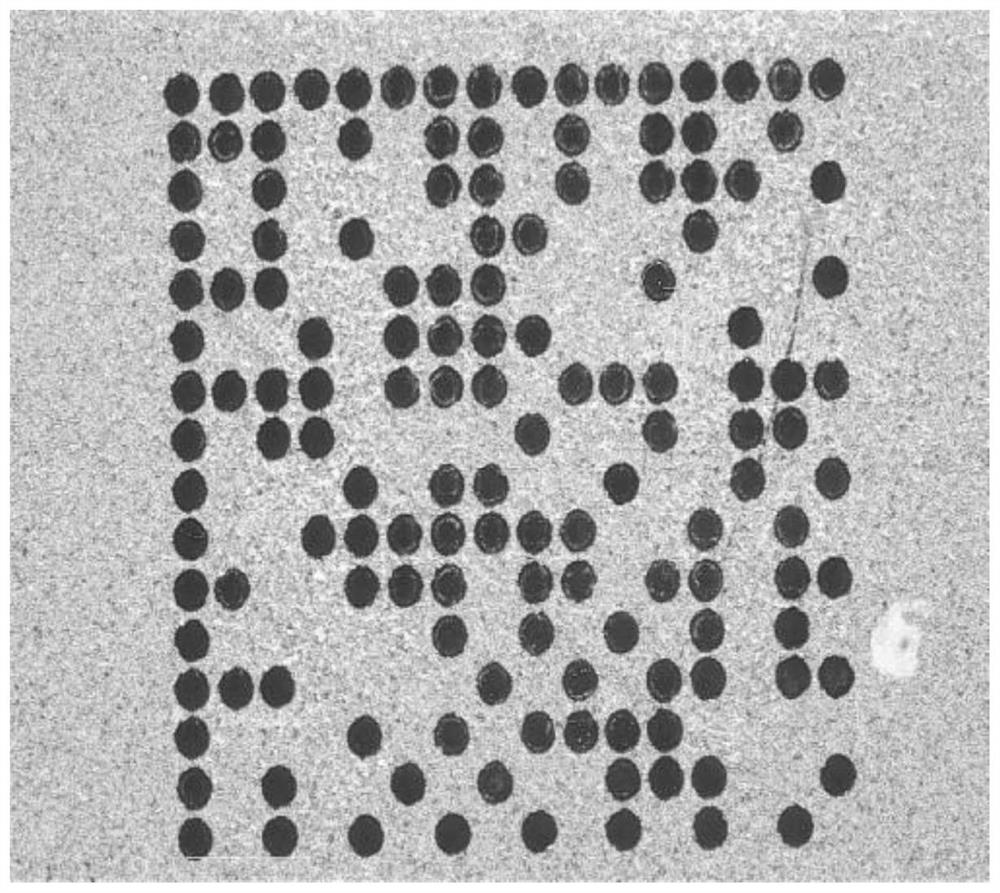

[0047] According to the above parameters to complete the embodiment, the laser processing effect diagram is figure 1 , CCD camera code reading standard is two-dimensional code ISO29158, AIM DPM mode, the results show that: the two-dimensional code grade reaches B level and above.

Embodiment 2

[0049] (1) NiP layer thickness 1.27um, Au layer thickness 0.028um;

[0050] (2) The laser focus spot size on the surface of gold-plated parts is 37.52um;

[0051] (3) The laser spot size before incident is 3.56mm;

[0052] (4) Push the pretreated gold-plated parts to the laser processing station, and press the gold-plated parts; when the laser receives the light signal, the laser processes the gold-plated parts according to the set laser parameters; after the processing is completed, The gold-plated parts are transported to the CCD reading and grading station, and finally enter the storage box.

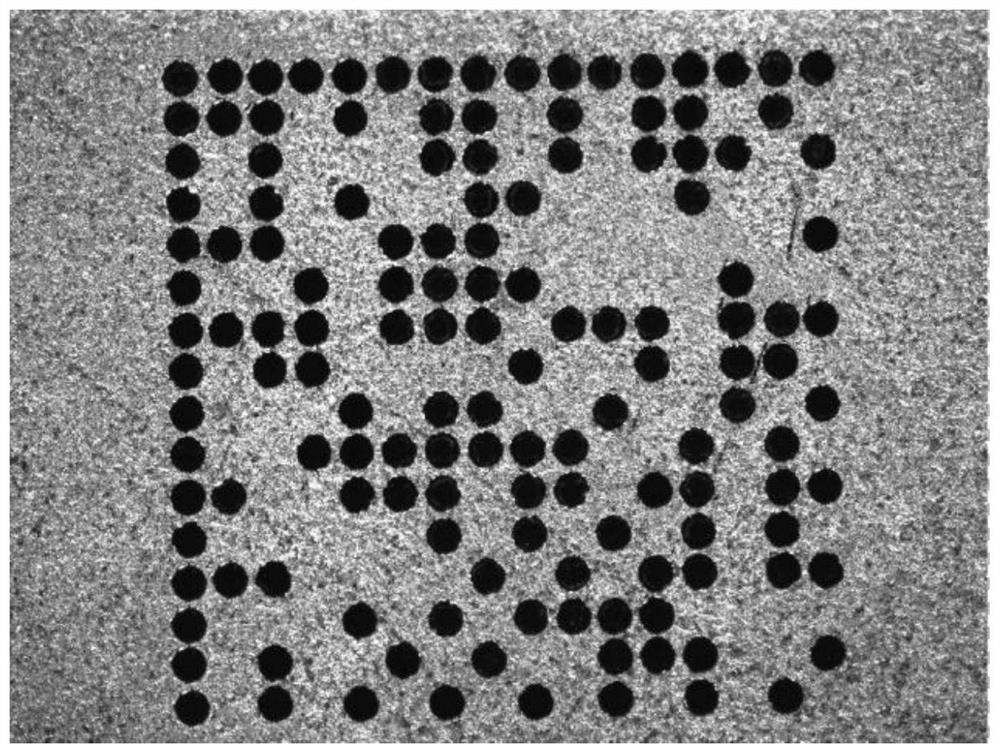

[0053] According to the above parameters to complete the embodiment, the laser processing effect diagram is figure 2 , CCD camera code reading standard is two-dimensional code ISO29158, AIM DPM mode, the results show that: the two-dimensional code grade reaches B level and above.

Embodiment 3

[0055] (1) NiP layer thickness 2.92um, Au layer thickness 0.072um;

[0056] (2) The laser focus spot size on the surface of gold-plated parts is 51.02um;

[0057] (3) The laser spot size before incident is 2.13mm;

[0058] (4) Push the pretreated gold-plated parts to the laser processing station, and press the gold-plated parts; when the laser receives the light signal, the laser processes the gold-plated parts according to the set laser parameters; after the processing is completed, The gold-plated parts are transported to the CCD reading and grading station, and finally enter the storage box.

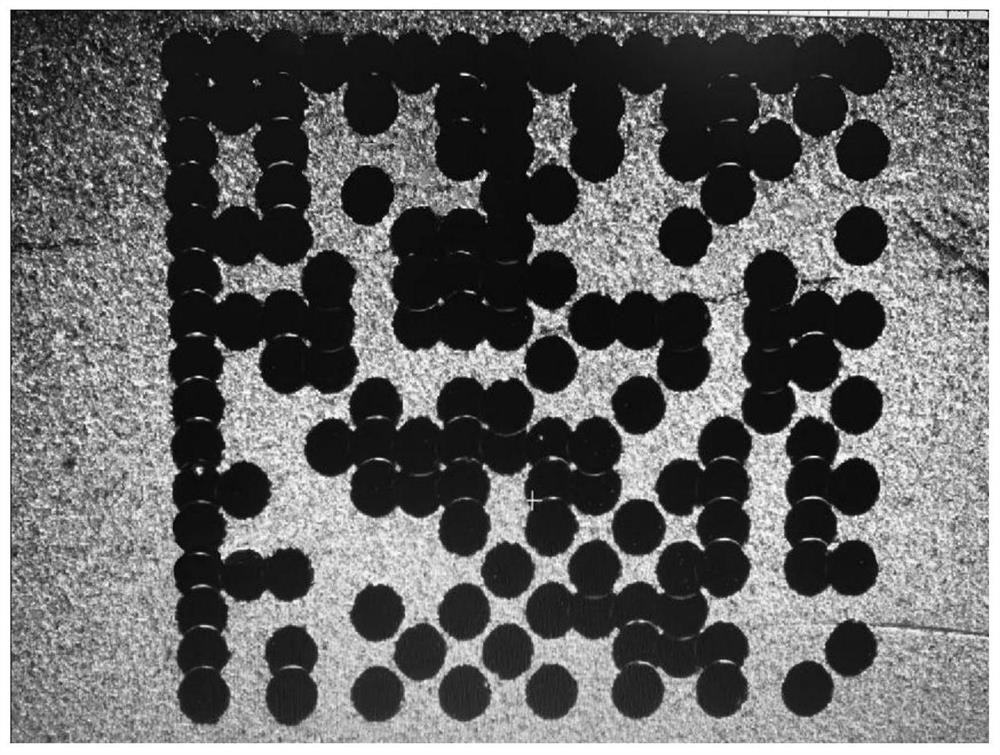

[0059] According to the above parameters to complete the embodiment, the laser processing effect diagram is image 3 , CCD camera code reading standard is two-dimensional code ISO29158, AIM DPM mode, the results show that: the two-dimensional code grade reaches B level and above.

[0060] The core of this specific embodiment lies in a method for improving the quality of two-dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com