Slidable main unit base of continuous drilling fluid circulating system

A circulation system and drilling fluid technology, applied in the field of petroleum drilling machinery, can solve the problem that the main engine cannot move laterally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

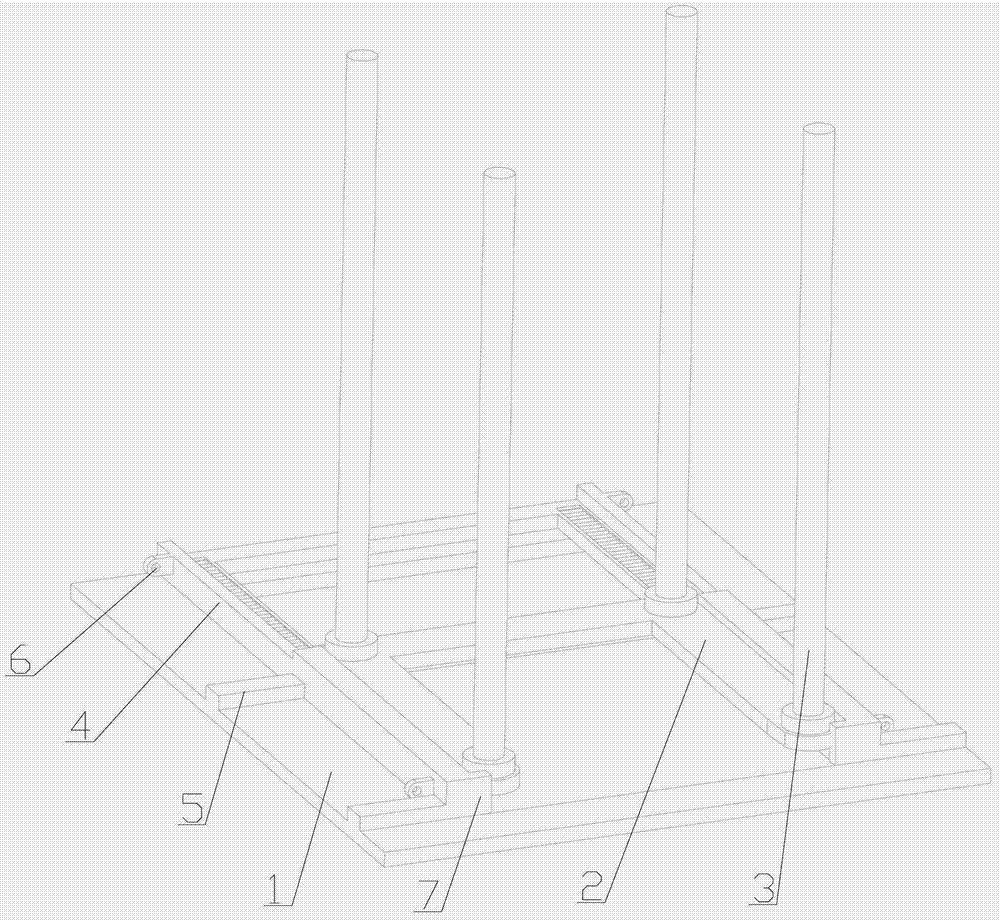

[0010] As shown in the accompanying drawings, the slidable base of the main engine of the drilling fluid continuous circulation system includes a base 1 , a carriage 2 and a hydraulic piston rod 3 . Both sides of the base 1 are fixed with sideways channel-shaped slideways 4, through which the slide frame 2 can move laterally. The top of the rear half of the slideway 4 is open, which is convenient for loading and unloading the slide frame 2. The bottom surface of the slideway 4 is a needle-type sliding surface, which reduces the frictional resistance of the carriage 2 . The front end of the slideway 4 is fixedly connected with a limiting plate 7 to limit the sliding frame 2 from sliding out of the slideway 4 . The carriage 2 is a U-shaped plate, the protruding parts on both sides of the carriage 2 are slidably connected in the slideway 4, the hydraulic piston rod 3 is vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com