Automatic production process and device of steel pipe bundle combined structural component

A technology of combined structure and production process, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high labor cost, low production efficiency, unstable product quality, etc., to ensure the quality of components, reduce the effect of component deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

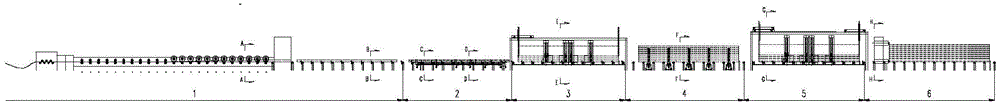

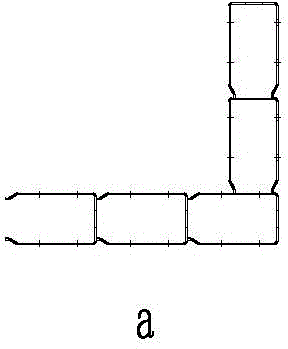

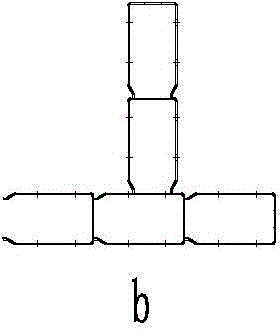

[0071] refer to Figure 1 to Figure 8c , an automated production process for a composite structural member of a steel pipe bundle, wherein the production process includes the following steps:

[0072] (1) Preparation of U-shaped steel pipes: On the cold-bending forming device 1, the steel coil raw materials of fixed width are continuously cold-bent and rolled into U-shaped steel pipes, and are automatically cut into U-shaped steel pipes with fixed lengths and openings facing upwards according to the requirements of the drawings. Shaped steel pipes to prepare profiles for subsequent processes;

[0073] (2) Directional material transfer of U-shaped steel pipes: After the above-mentioned cold-bending forming device 1, utilize the directional material-transfer device to make the opening of the U-shaped steel pipes face downwards, thereby realizing the directional material transfer of U-shaped steel pipes, and supplying material for the subsequent welding process. material;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com