Labyrinth Sealing Device of Marine Auxiliary Blower

A technology of labyrinth seals and blowers, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, non-variable pumps, etc., can solve problems such as short service life, easy deformation and damage, and affecting sealing performance. Achieve excellent wear resistance, long service life and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments are not used to limit the scope of the present invention, and all equivalent changes and modifications made according to the contents of this specification belong to the present invention The scope of technology to be protected by the patent application.

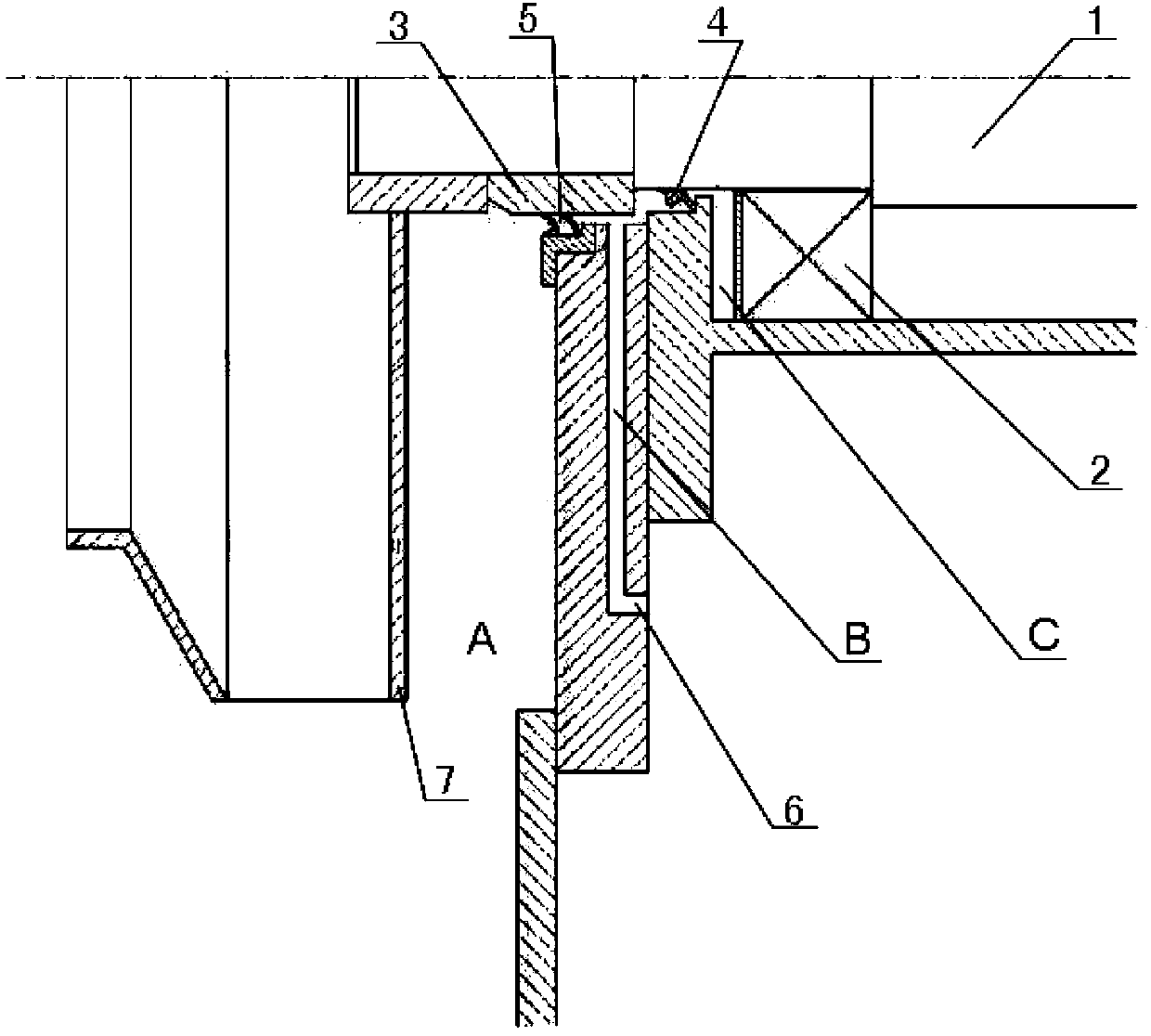

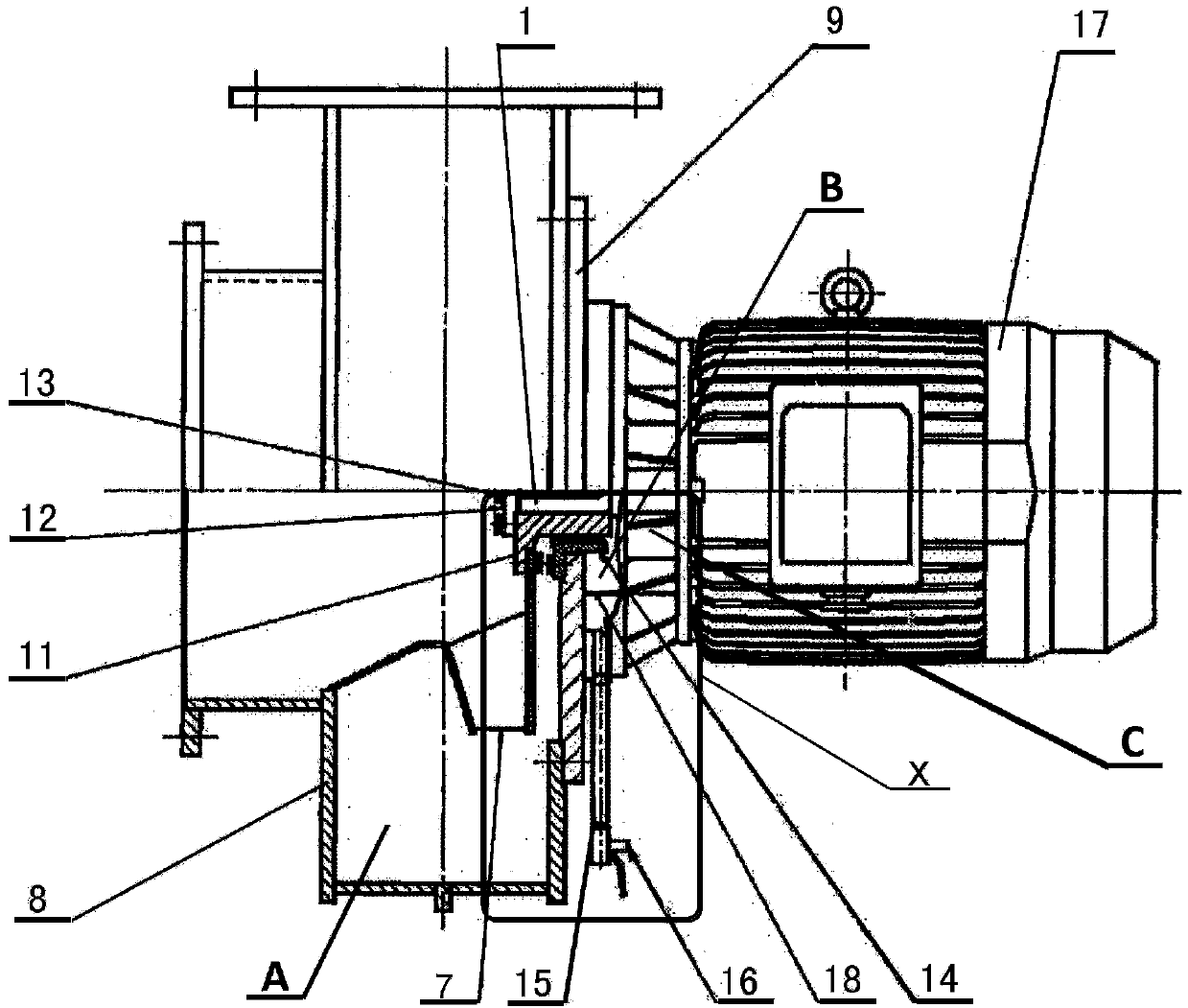

[0035] The labyrinth sealing device of the marine auxiliary blower described in the present invention is used for the auxiliary blower of the ship, please refer to figure 2 , the illustrated marine auxiliary blower includes an impeller 7, an impeller housing 8 and a motor 17, the motor 17 has a motor shaft 1, and the sealing device is arranged around the motor shaft 1.

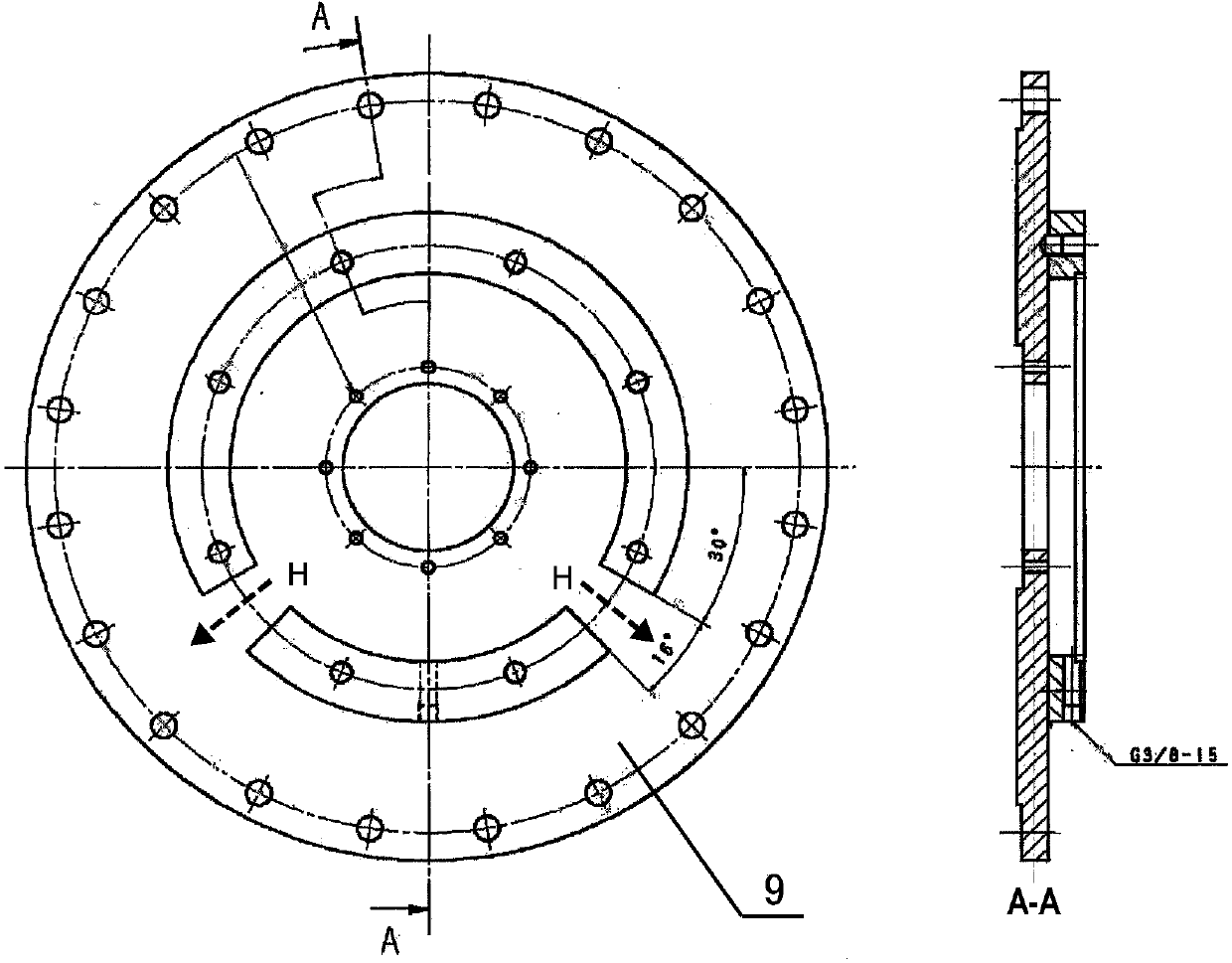

[0036] see image 3 , which shows the labyrinth seal device of the marine auxiliary blower, including the impeller seat 11, the locking disc 12, the labyrinth seal 14, the stepped flange 9, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com