High-temperature discharging valve

A discharge valve, high temperature technology, applied in the valve details, valve device, valve shell structure and other directions, can solve the temperature use range and use occasion restrictions, plastic sealing ring erosion or scratches, discharge valve performance degradation, etc. problems, to protect the performance and life, prevent leakage, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

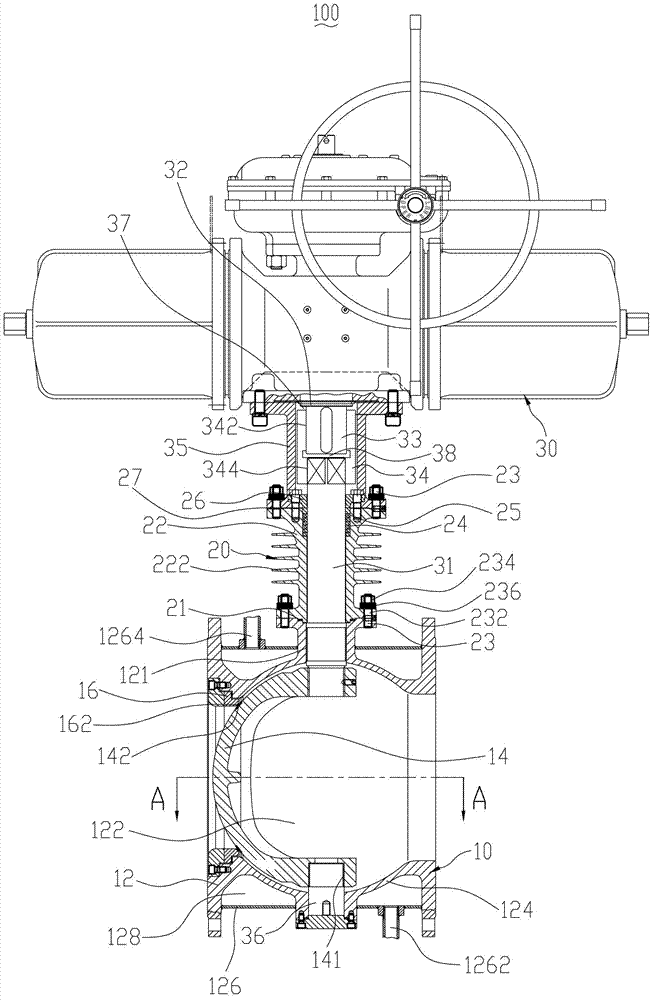

[0044] Please check figure 1 , a high-temperature unloading valve 100 of the present invention, comprising: a valve body part 10 for allowing high-temperature medium to circulate or block flow, a heat dissipation part 20 for dissipating heat, and a valve body part 10 for driving the action Drive part 30. The driving part 30 , the heat dissipation part 20 , and the valve body part 10 are arranged sequentially from top to bottom.

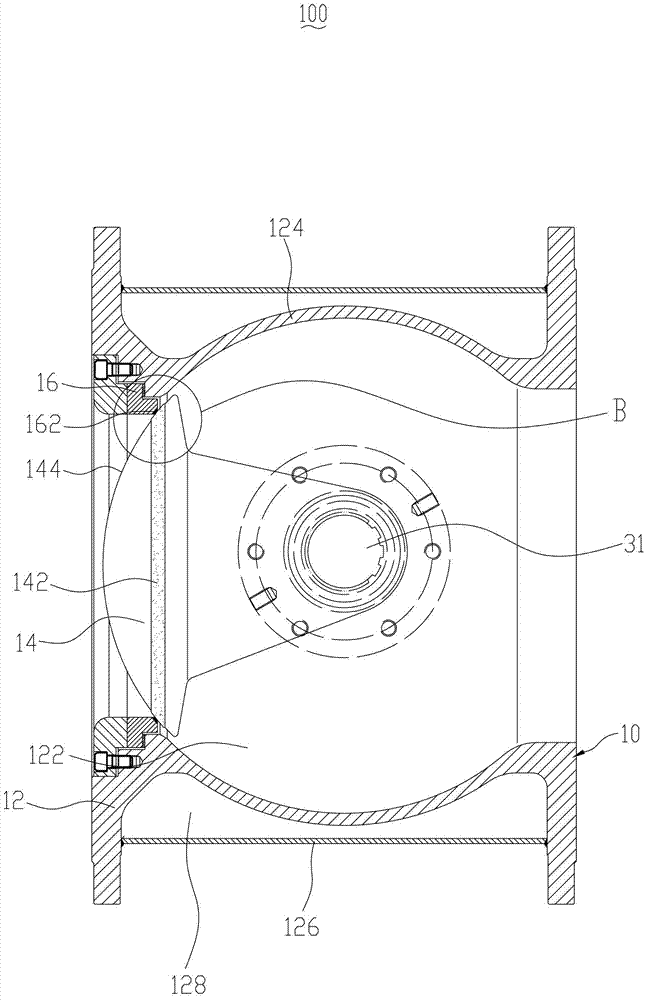

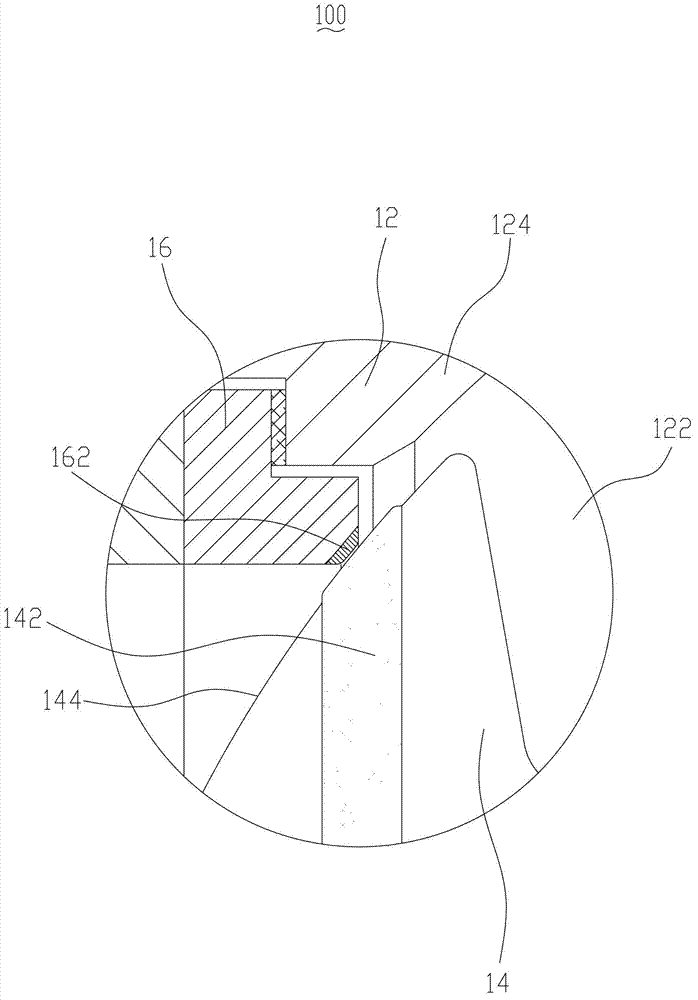

[0045] Please refer to figure 1 and figure 2, the valve body part 10 includes a valve body 12 , a hemispherical body 14 and a valve seat 16 . A channel 122 is transversely penetrating through the middle of the valve body 12 , and the medium flows through the channel 122 from left to right. The valve body 12 includes a sidewall 124 and a cooling jacket 126 disposed along the entire circumference. The sidewall 124 surrounds the channel 122 . The cooling jacket 126 is located outside the sidewall 124 . The cooling jacket 126 and the side wall 124...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com