Heat exchanger for cinder flushing water of blast furnace

A blast furnace slag flushing water and heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the blockage of heat exchange equipment, can not be used for solid particles and suspended solids hot water waste heat recovery, etc. problem, to achieve the effect of small heat dissipation loss, material saving, and improvement of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

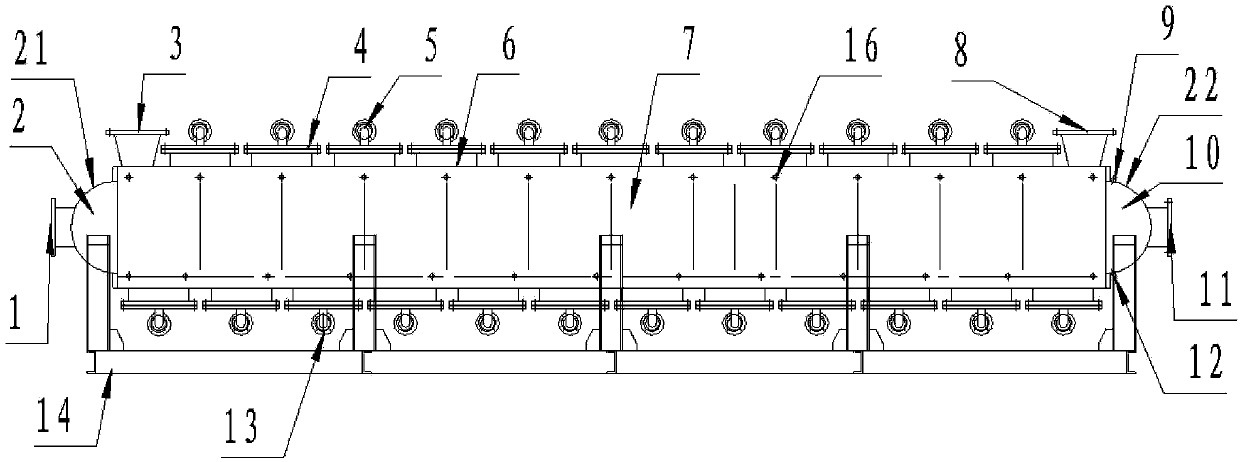

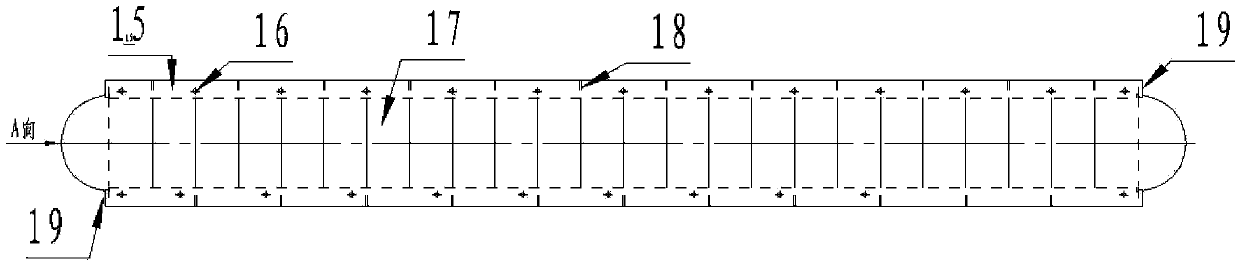

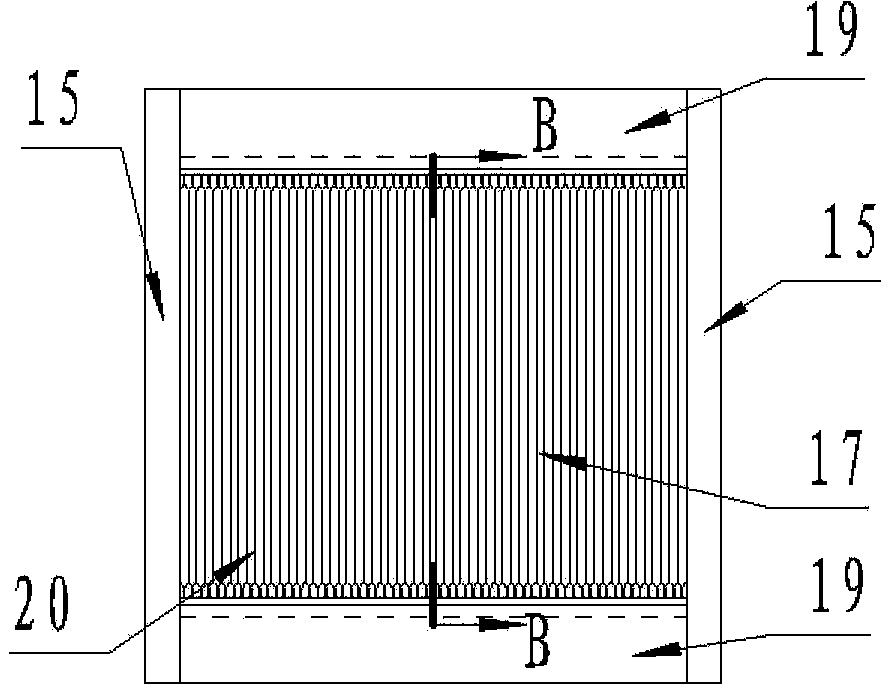

[0020] Embodiment 1, a blast furnace slag flushing water heat exchanger, which is characterized in that the two ends of the plate bundle 7 welded by corrugated plates are semi-cylindrical front and rear tube boxes, and the top surface of the plate bundle is equipped with an upper cover plate and a plate bundle The bottom surface is equipped with a lower cover plate. Both ends of the upper and lower cover plates are provided with blocking plates 19 which are welded to the front and rear pipe boxes. The upper and lower cover plates are respectively welded by the cover plates 6 with overhaul holes 4. The plate 15 is installed on the support 14, the front pipe box 2 is equipped with a circulating water inlet 1, the rear pipe box 10 is equipped with a circulating water outlet 11, and the upper cover plate near the end of the front pipe box is provided with a slag flushing water outlet 3. A slag flushing water inlet 8 is provided on the upper cover plate near one end of the rear pipe ...

Embodiment 2

[0021] Embodiment 2, a blast furnace slag flushing water heat exchanger, which is characterized in that the plate bundle 7 welded by corrugated plates has semi-cylindrical front and rear tube boxes at both ends, and the top surface of the plate bundle is equipped with an upper cover plate and a plate bundle The bottom surface is equipped with a lower cover plate. Both ends of the upper and lower cover plates are provided with blocking plates 19 which are welded to the front and rear pipe boxes. The upper and lower cover plates are respectively welded by the cover plates 6 with overhaul holes 4. The plate 15 is installed on the support 14, the front pipe box 2 is equipped with a circulating water inlet 1, the rear pipe box 10 is equipped with a circulating water outlet 11, and the upper cover plate near the end of the front pipe box is provided with a slag flushing water outlet 3. A slag flushing water inlet 8 is provided on the upper cover plate near one end of the rear pipe box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com