Defect detecting and repairing device and method of optical sensor array panel

A sensor array and array panel technology, applied in the field of optical sensors, can solve complex, error-prone, and optical sensor array panel defects and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

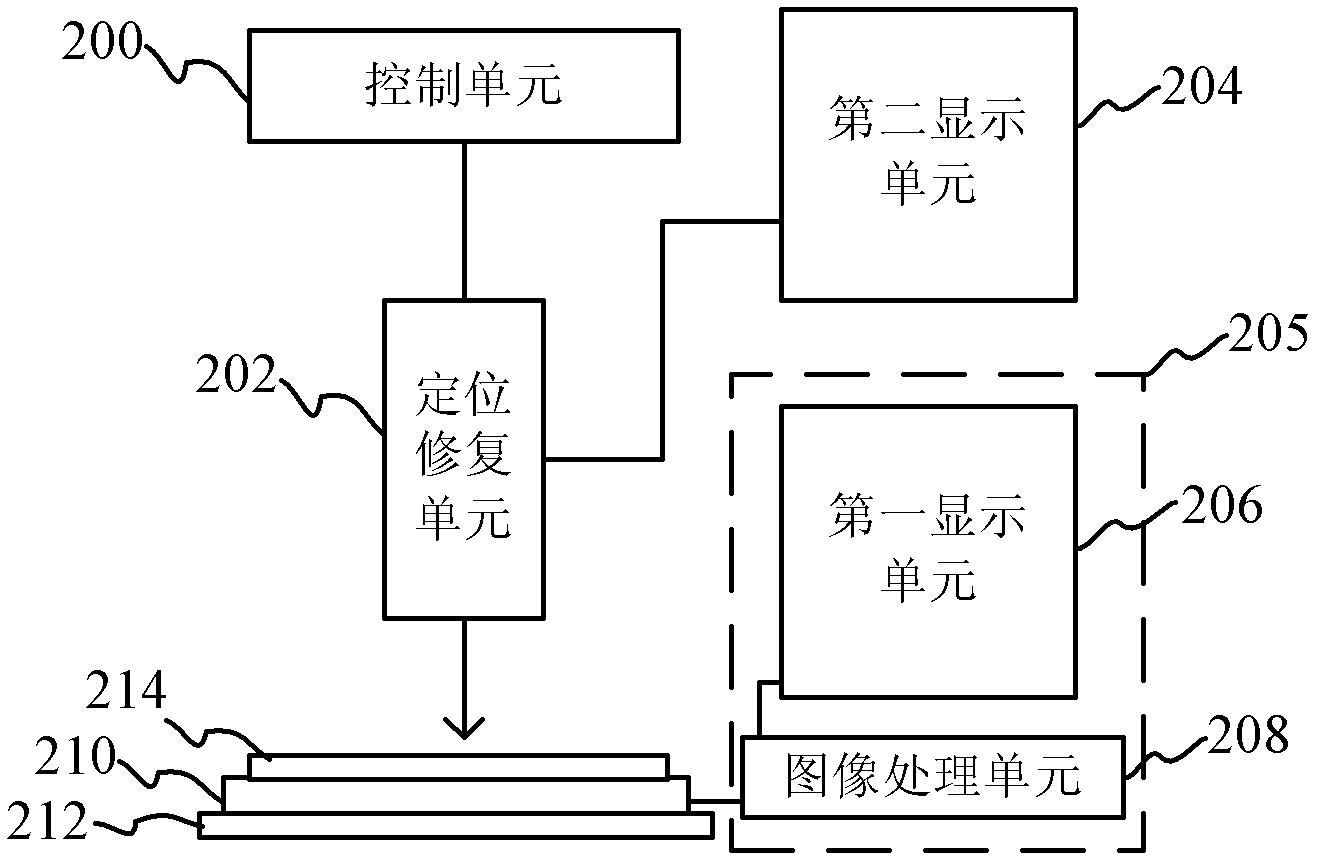

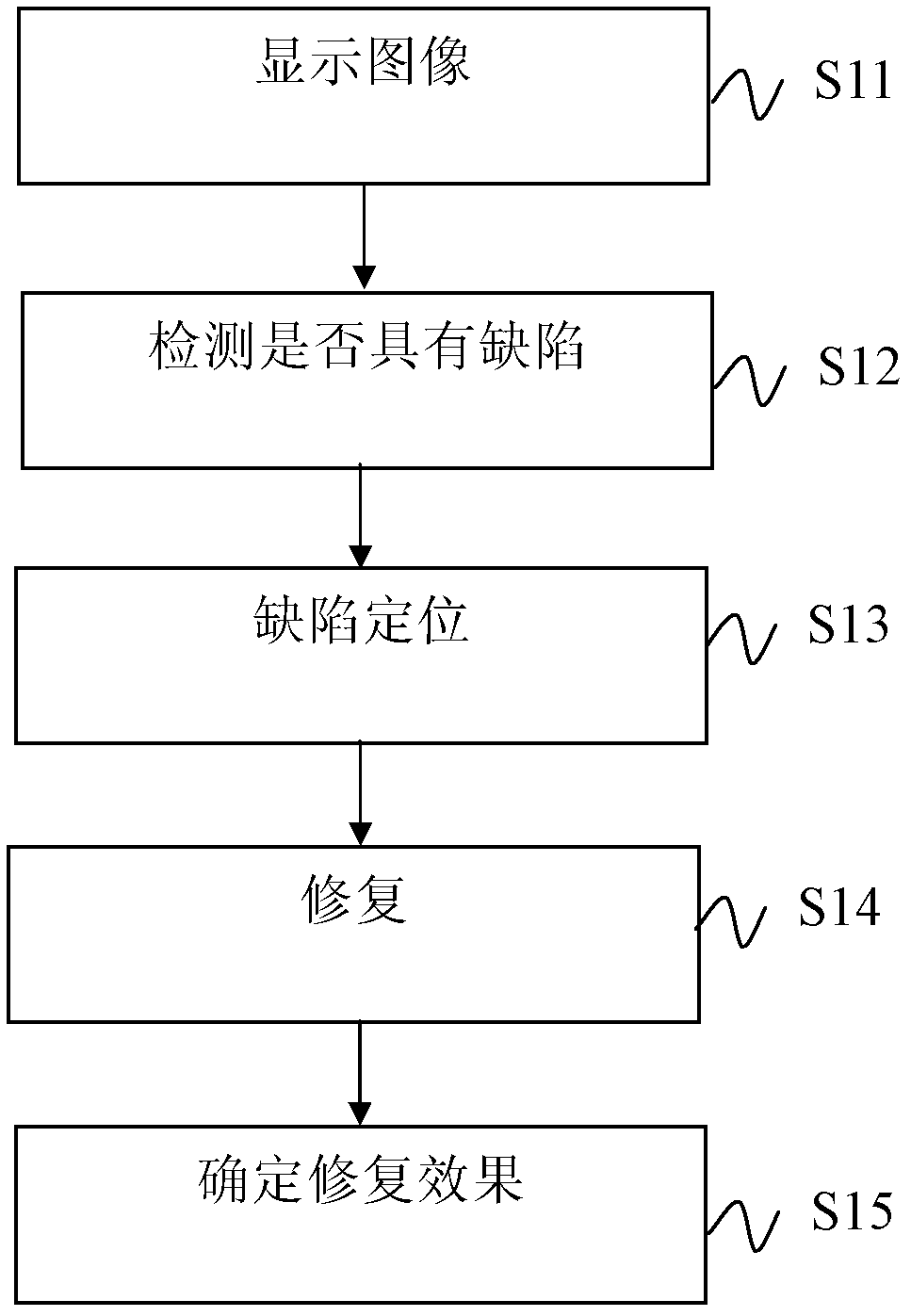

[0031] Such as figure 1 As shown, a device for detecting and repairing defects in an optical sensor array panel includes: a detection unit 210 for detecting an analog electrical signal output by an optical sensor array panel 214 placed thereon, and converting the analog electrical signal into a digital electrical signal; Process the display unit 205, convert the digital electrical signal detected by the detection unit 210 into an image signal, and convert the image signal into an image for display, and the image can feed back whether the photosensor array panel has defects; the positioning repair unit 202, The defects on the photosensor array panel 214 are located, and the located defects are repaired.

[0032] In this embodiment, the positioning repair unit 202 includes a laser source, a microscopic unit and a camera unit. The laser light produced by the laser source is irradiated on the photosensor array panel 214 placed on the detection unit 210, and the defects on the pho...

Embodiment 2

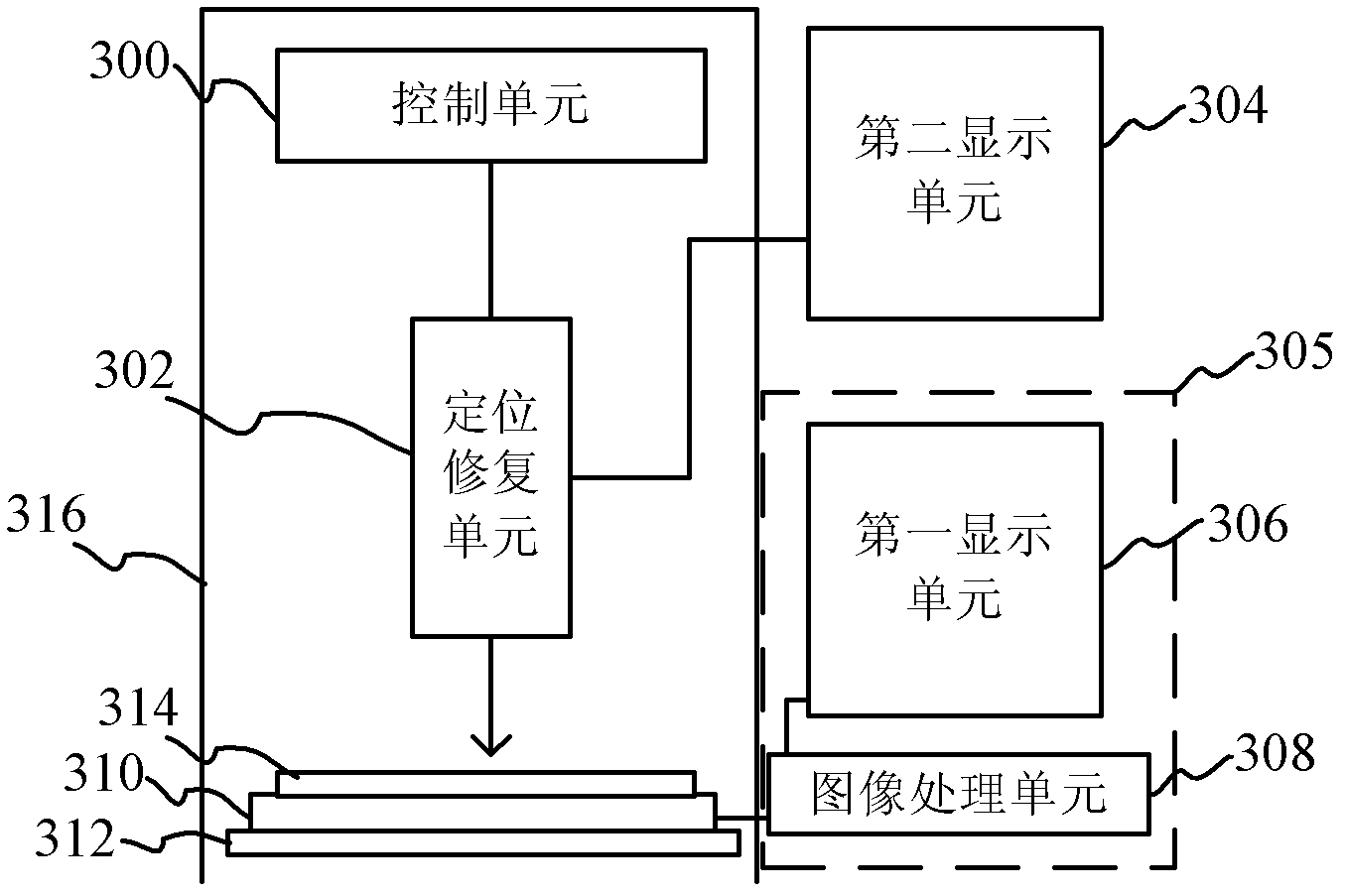

[0051] Such as image 3 As shown, a device for detecting and repairing defects of an optical sensor array panel includes: a base 312 for carrying a detection unit 310 . The detection unit 310 is configured to detect the analog electrical signal output by the light sensor array panel 314 placed thereon, and convert the analog electrical signal into a digital electrical signal. The processing and display unit 305 includes: an image processing unit 308 and a first display unit 306; the image processing unit 308 is electrically connected to the detection unit 310 to convert the digital electrical signal detected by the detection unit 310 into an image signal; The first display unit 306 is used to display the image signal obtained by the image processing unit 308 as an image. The positioning and repairing unit 302 locates defects on the photosensor array panel 314 and repairs the located defects. The second display unit 304 is electrically connected to the positioning and repairi...

Embodiment 3

[0062] Such as Figure 4 As shown, an optical sensor array panel defect detection and repairing device includes: a base 412 for carrying a detection unit 410 . The detection unit 410 is configured to detect the analog electric signal output by the light sensor array panel 414 placed thereon, and convert the electric signal into a digital electric signal. The processing display unit 405 includes: an image processing unit 408 and a first display unit 406; the image processing unit 408 is electrically connected to the detection unit 410, and is used to convert the electrical signal detected by the detection unit 410 into an image signal; the The first display unit 406 is configured to convert the image signal processed by the image processing unit 408 into an image for display. The positioning and repairing unit 402 locates defects on the photosensor array panel 414 and repairs the located defects. The second display unit 404 is electrically connected to the positioning and rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com