On-line detection method of small defect on metal plate strip surface

A metal strip and detection method technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as increased equipment costs, insufficient detection capabilities for small defects, and increased data volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

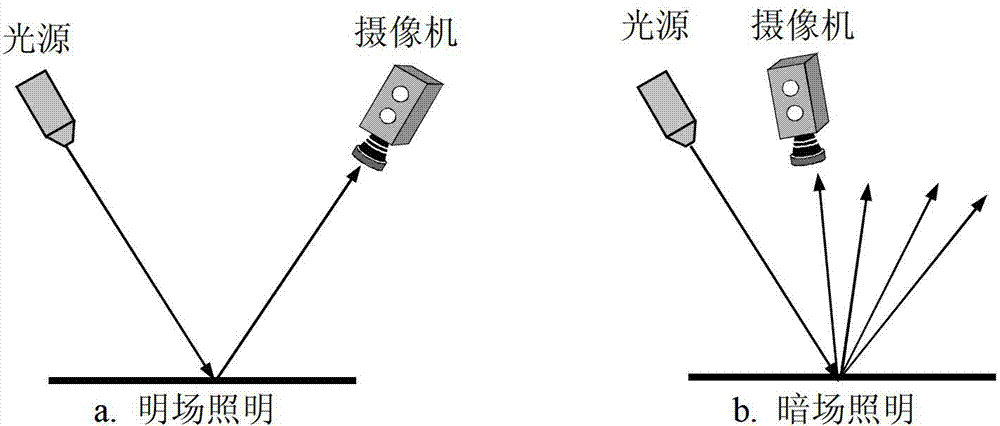

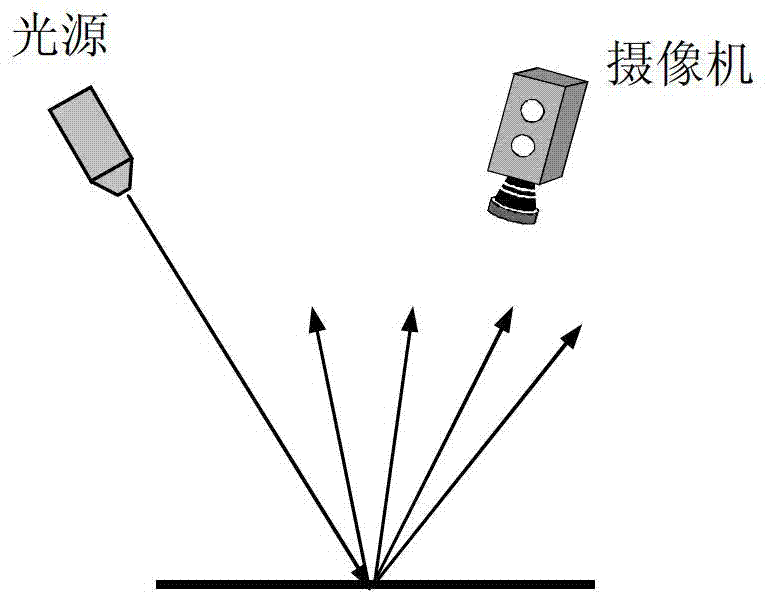

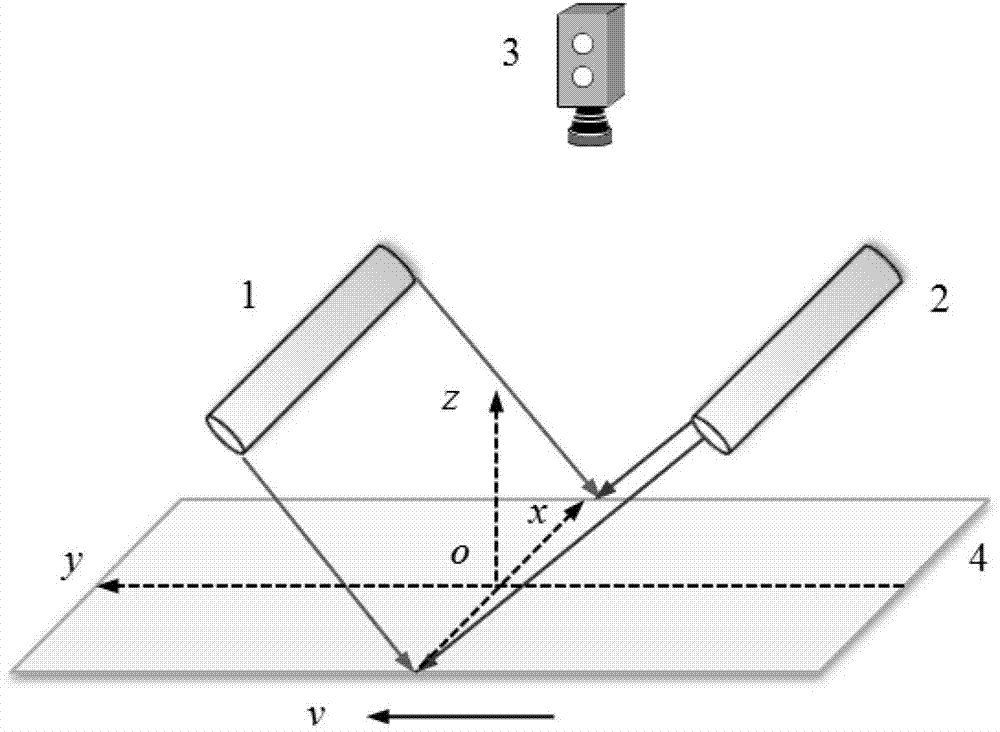

[0026] image 3 In, the camera 3 is placed in the direction perpendicular to the surface of the metal strip 4 . The light source 1 is placed on the same side as the running direction v of the camera 3 and the metal strip 4, and its incident angle is α. The light source 2 is placed on the opposite side of the camera 3 to the running direction v of the metal strip 4, and its incident angle is also α. The luminous intensity of the light source 2 is equal to that of the light source 1, and the height from the surface of the metal strip is also equal. The light emitted by the light source 1 and the light source 2 irradiates the same area of the metal strip 4, and the camera 3 collects images of this area. Since the camera 3 is a color linear CCD camera, the images collected by the camera 3 can be separated into R and B channel images, corresponding to the reflected light images of the light source 2 and the light source 1 respectively.

[0027] According to the principle of Ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com