Up-and-down constant-temperature parameter identifying method for testing thermal interface material performance

A parameter identification method and technology of thermal interface materials, applied in the field of performance testing of thermal interface materials, can solve the problems of temperature measurement uncertainty error, difficult interface contact thermal resistance measurement accuracy, etc., achieve high-precision contact thermal resistance and eliminate inconsistencies The effect of sexual error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

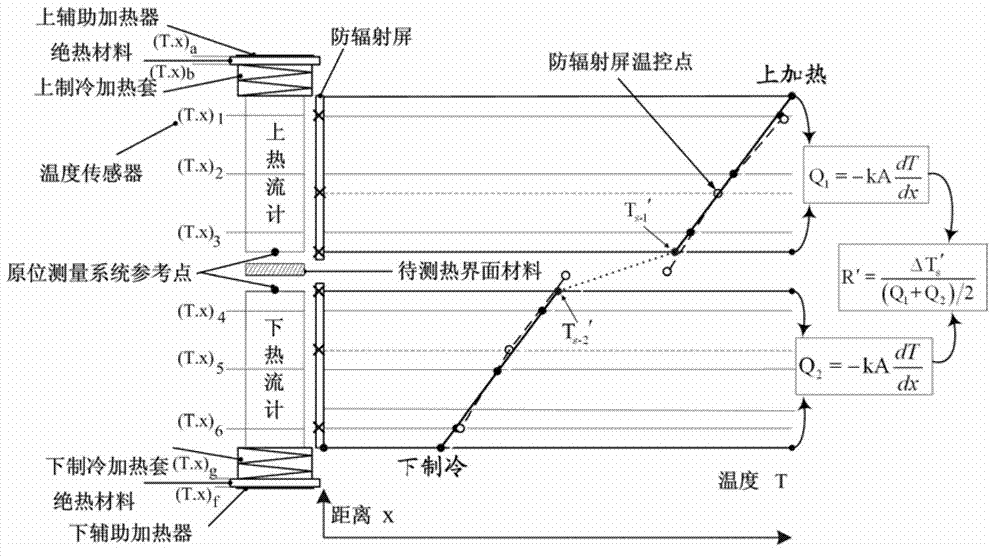

[0029] Based on the American national standard ASTM D5470, the present invention proposes a method to measure the performance of the thermal interface material by using the upper and lower constant temperature parameter identification method. Constant temperature parameter identification eliminates the inconsistency error and heat loss error of each temperature sensor, combined with the controllable thermal radiation shield and auxiliary measures to reduce heat flow loss, to achieve the purpose of high-precision testing of thermal physical parameters of thermal interface materials, The method can measure the interface contact thermal resistance and the effective equivalent thermal conductivity after filling the thermal interface material with high precision.

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

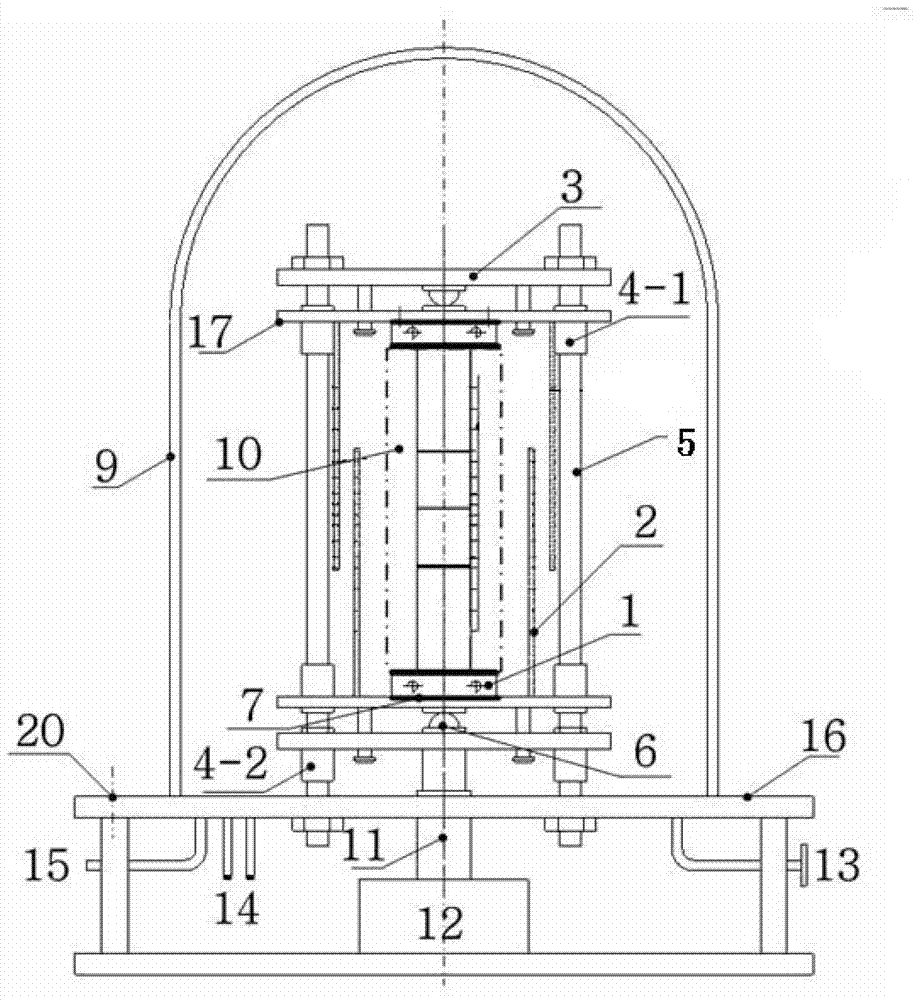

[0031] combine figure 1 , the present invention discloses a device for measuring thermal interface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com