Monitoring system and method of flow industrial pipe network system

A monitoring system and process industry technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as heavy workload, safety accidents, economic losses, etc., and achieve the effect of accurate scheduling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific implementation will be described in detail below in conjunction with the accompanying drawings.

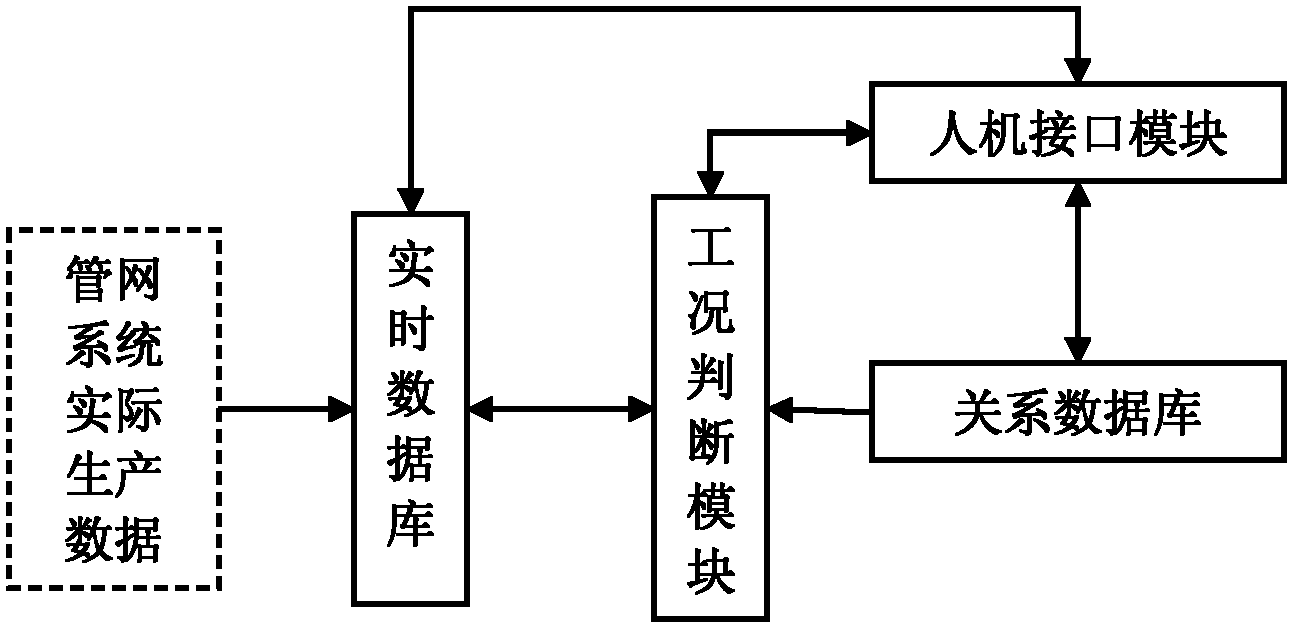

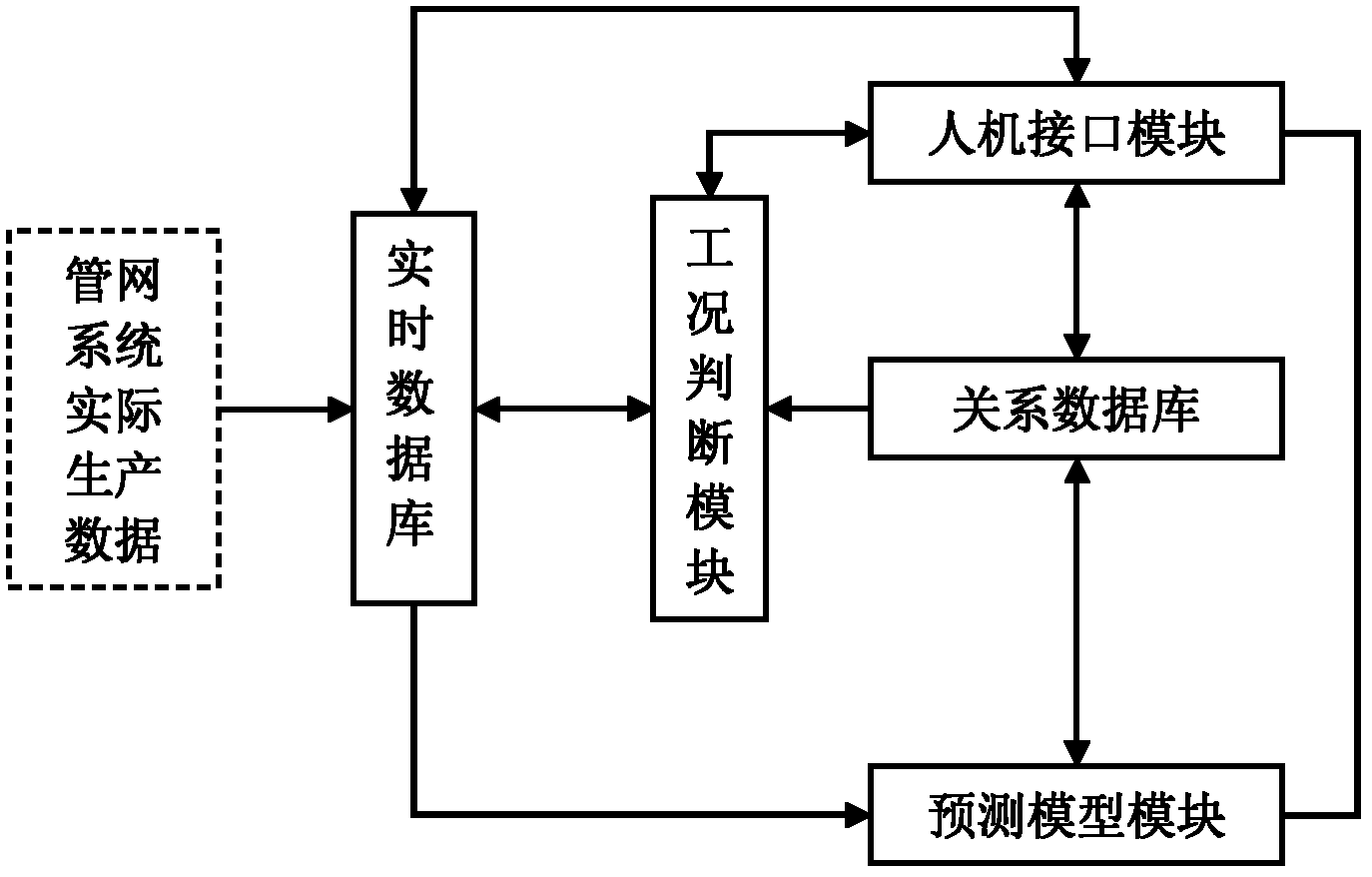

[0060] Figure 2a with Figure 2b is the structural block diagram of the monitoring system, from Figure 2a with Figure 2b It can be seen that the connection relationship between the modules.

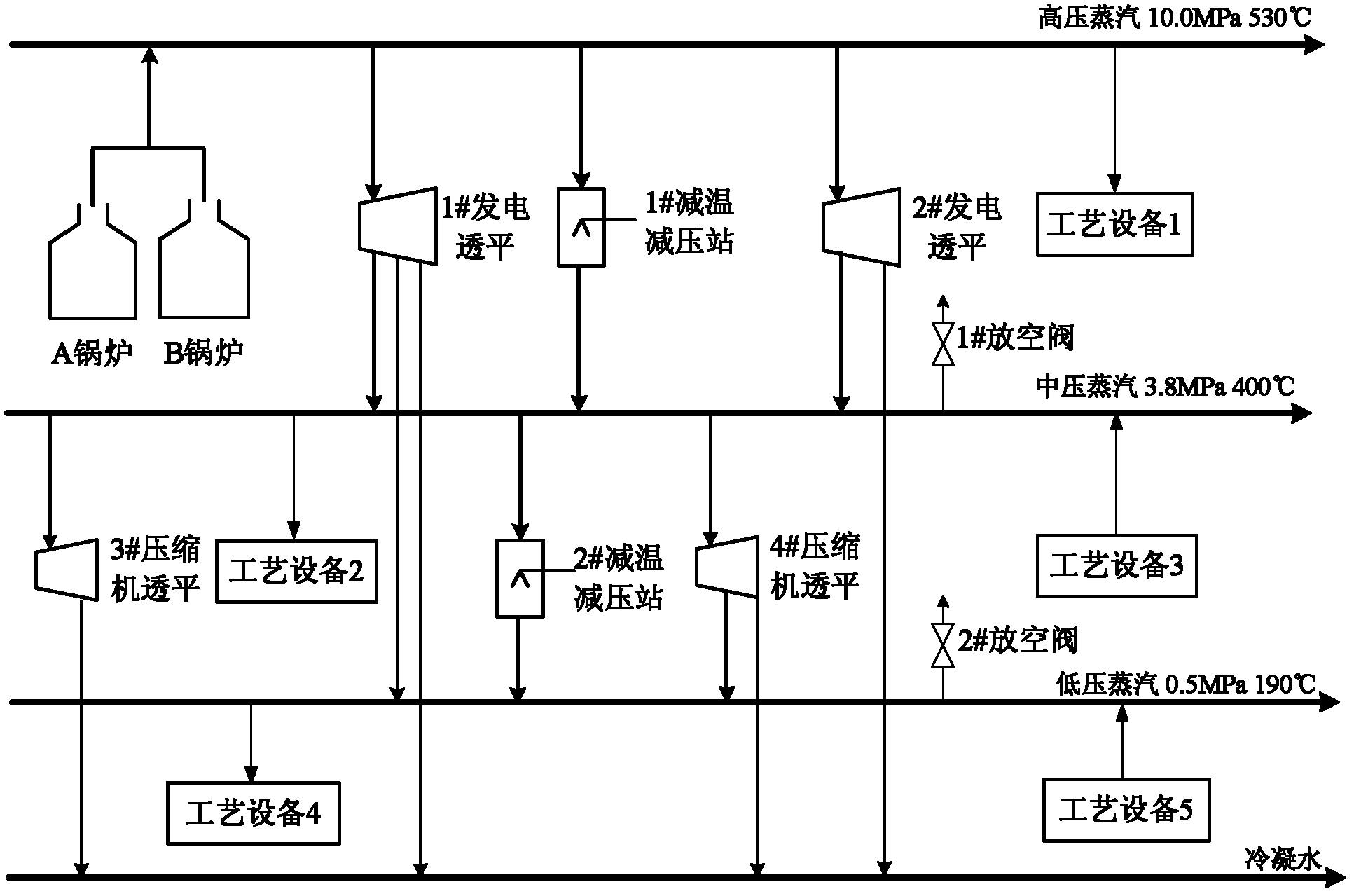

[0061] The present invention provides a monitoring system and method for the pipeline network system of various energy media (including steam, coal gas, gas, water, etc.), which can automatically detect abnormal events, working conditions and other working conditions of the pipeline network system Operation information, providing monitoring personnel with functions such as on-site parameter monitoring, energy parameter monitoring, and pipeline network operation status judgment, realizing the monitoring data processing of the pipeline network system, and displaying the obtained results to monitoring personnel and dispatchers, so as to improve the timely dispatching s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com