Optical touch panel, manufacturing method thereof, and optical touch display panel

A technology of a touch panel and a manufacturing method, which is applied to instruments, electrical digital data processing, and input/output processes of data processing, etc. Simple process, low production cost, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

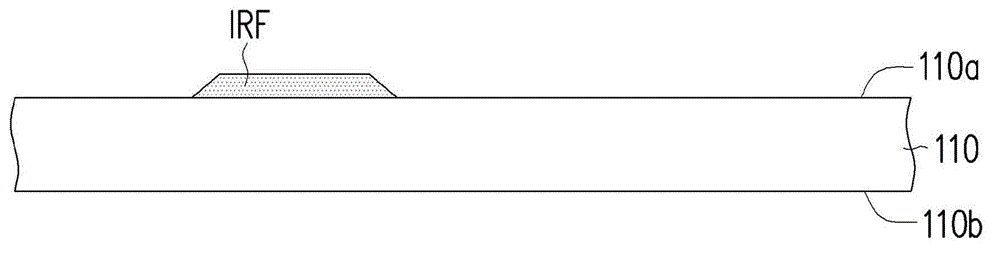

[0050] Figure 1A to Figure 1I It is a schematic cross-sectional view of the manufacturing method of the optical touch panel according to the first embodiment of the present invention. Please refer to Figure 1A Firstly, the substrate 110 is provided, wherein the substrate 110 has an inner surface 110a and an outer surface 110b, wherein the outer surface 110b faces the user. Next, an infrared filter layer IRF is formed on the inner surface 110 a of the substrate 110 . In this embodiment, the material of the infrared filter layer IRF includes germanium compound or germanium silicon compound, for example.

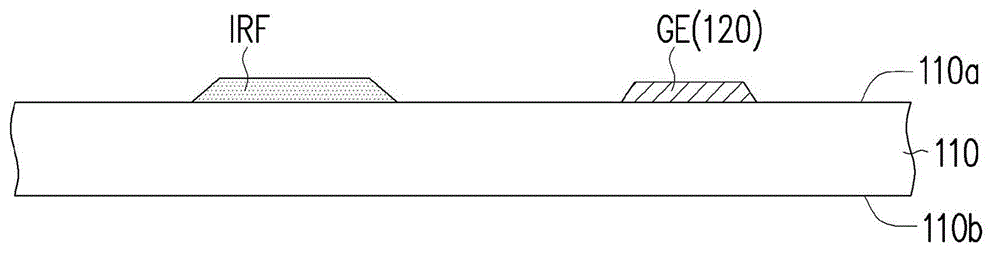

[0051] Please refer to Figure 1B, and then, a first patterned conductive layer 120 is formed on the substrate 110, the first patterned conductive layer 120 includes at least one gate GE and at least one scanning line (not marked) connected to the gate GE, wherein the gate GE and The scan lines are located on the inner surface 110 a of the substrate 110 . The material of ...

no. 2 example

[0064] Figure 2A to Figure 2I It is a schematic cross-sectional view of the manufacturing method of the optical touch panel according to the second embodiment of the present invention. Since the components of the optical touch panel of the second embodiment are the same as those described in the first embodiment, the steps and differences will be described below, and the remaining parts can refer to the first embodiment, and will not be repeated here. Please refer to Figure 2A , firstly, a substrate 110 is provided, wherein the substrate 110 has an inner surface 110a. Next, a first patterned conductive layer 120 is formed on the inner surface 110 a of the substrate 110 . The first patterned conductive layer 120 includes at least one gate GE and at least one scan line (not shown) connected to the gate GE.

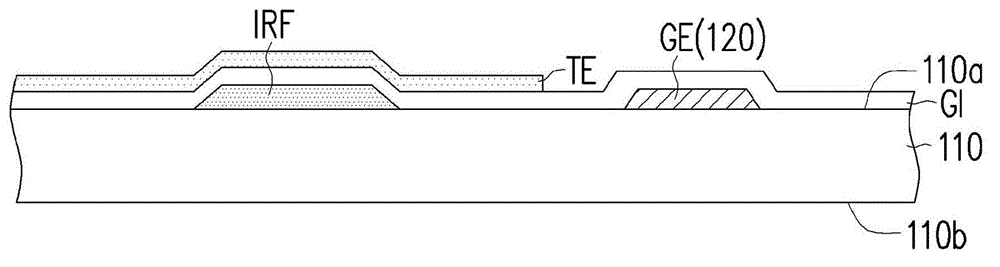

[0065] Please refer to Figure 2B , and then, a first dielectric layer GI is formed on the substrate 110 to cover the gate GE and the scan line SL. Next, an infrared f...

no. 3 example

[0074] Figure 3A and Figure 3D It is a schematic cross-sectional view of the manufacturing method of the optical touch display panel according to the third embodiment of the present invention. Please refer to Figure 3A , firstly, the first substrate 110 is provided, wherein the inner surface 110a of the first substrate 110 has been formed as Figure 1H structure shown. Among them, such as Figure 1H The structure shown can be fabricated by the method described in the first embodiment or the second embodiment.

[0075] Please refer to Figure 3B , and then, a black matrix BM may be formed on the inner surface 110a of the first substrate 110 first. Then, a color filter layer CF may be formed on the inner surface 110 a of the first substrate 110 . Next, a protection layer PV2 and a transparent conductive layer TCL may be formed on the inner surface 110 a of the first substrate 110 , wherein the protection layer PV2 covers the black matrix BM and the color filter layer C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com