Method for manufacturing embedded touch control panel and embedded touch control panel manufactured by method

A touch panel, built-in technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve problems such as unsatisfactory pictures and poor light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to understand the technical content of the present invention, specific examples are specifically cited as follows.

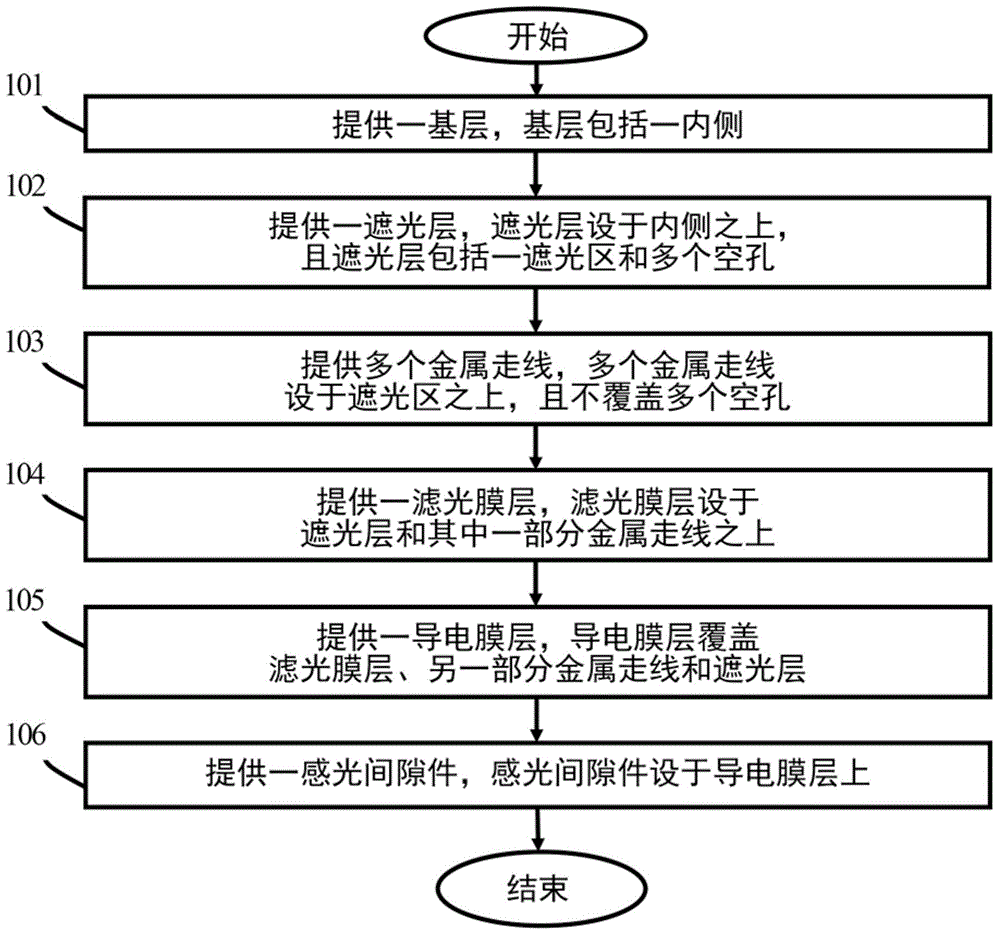

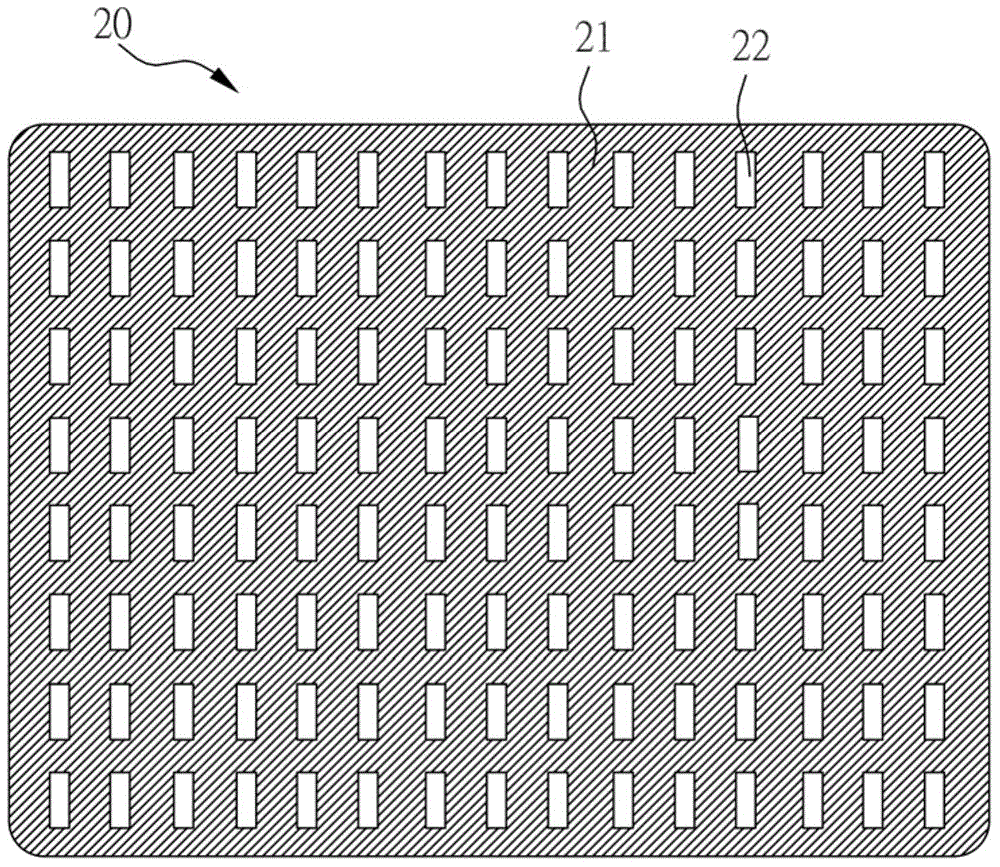

[0046] Please refer to the following Figure 1 to Figure 12 A method for manufacturing an in-cell touch panel and the in-cell touch panel according to an embodiment of the present invention. figure 1 It is a flowchart of steps of a method for manufacturing an in-cell touch panel according to an embodiment of the present invention; figure 2 is a schematic diagram of the base layer of an embodiment of the present invention; image 3 is a top view of a light-shielding layer according to an embodiment of the present invention; Figure 4 It is a schematic diagram of the light-shielding layer and the base layer of an embodiment of the present invention; Figure 5 It is a top view of a light-shielding layer provided with metal traces according to an embodiment of the present invention; Image 6 It is a schematic diagram of a light-shielding layer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com