Method for finite element optimization of bolt pretightening force and bolt structural design

A technology of bolt pretightening force and bolt structure, applied in calculation, special data processing applications, instruments, etc., can solve the problems of difficult bolt structure optimization design, bolt pretightening force inconvenience, etc., achieve fast calculation, improve accuracy and reliability Good performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

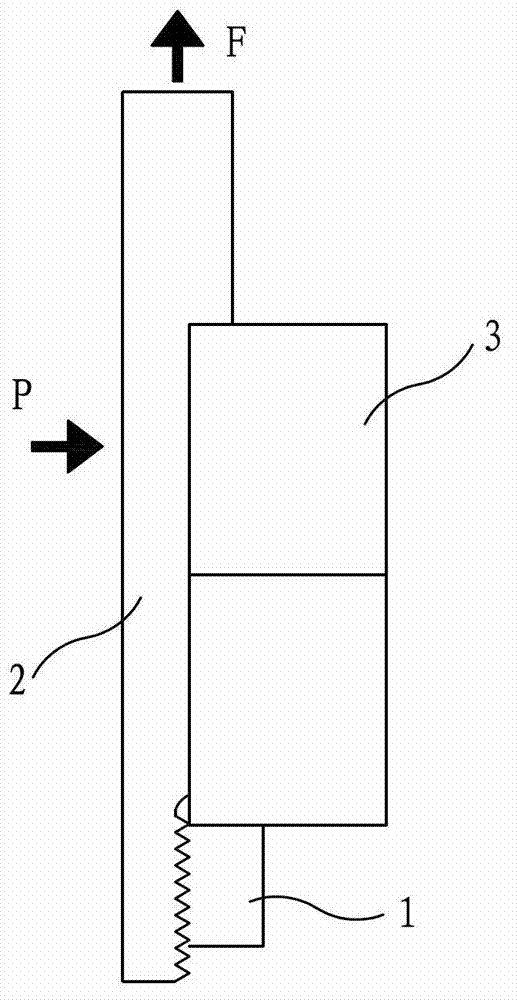

[0026] Now combined with the accompanying drawings, that is, Figure 1 to Figure 4 As shown, the embodiments of the present invention are described in detail, and the purpose, features and advantages of the present invention are explained. The finite element method for optimizing the bolt pretightening force mainly includes the following steps.

[0027] 1. Establish the finite element analysis model of the bolted connection structure.

[0028] The present invention considers the geometric characteristics of the thread helix and the complex nonlinear factors in the component connection, refines the three-dimensional helical thread structure, and simplifies it into a two-dimensional symmetric problem without loss of accuracy; at the same time, the thread contact and stress concentration In order to obtain a more accurate stress state, the regional unit is locally refined, and the finite element analysis model of the bolted connection structure is as follows: figure 1 shown.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com