Silencing cotton structure

A technology of sound-absorbing cotton and apparent density, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of poor resilience, reduced sound insulation effect, limited use range, etc., and achieve good compression resilience and absorption opportunities. The effect of increasing, long-lasting noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

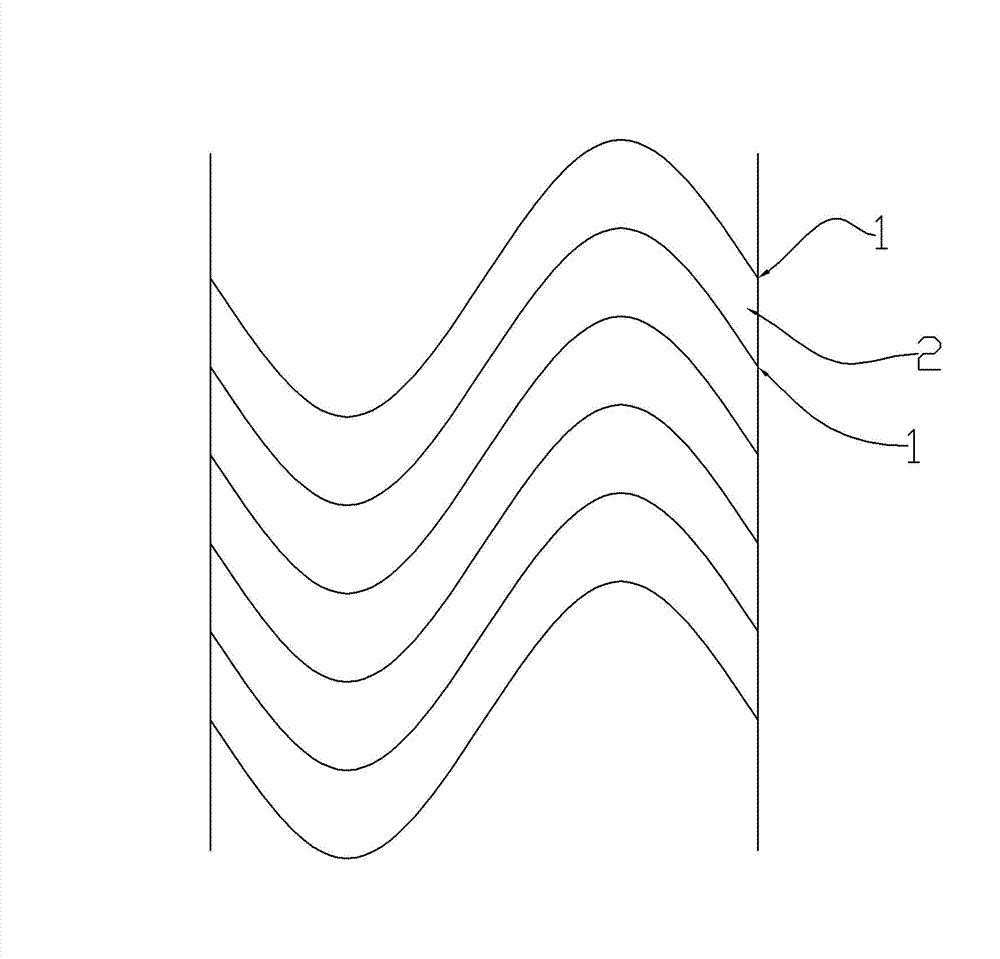

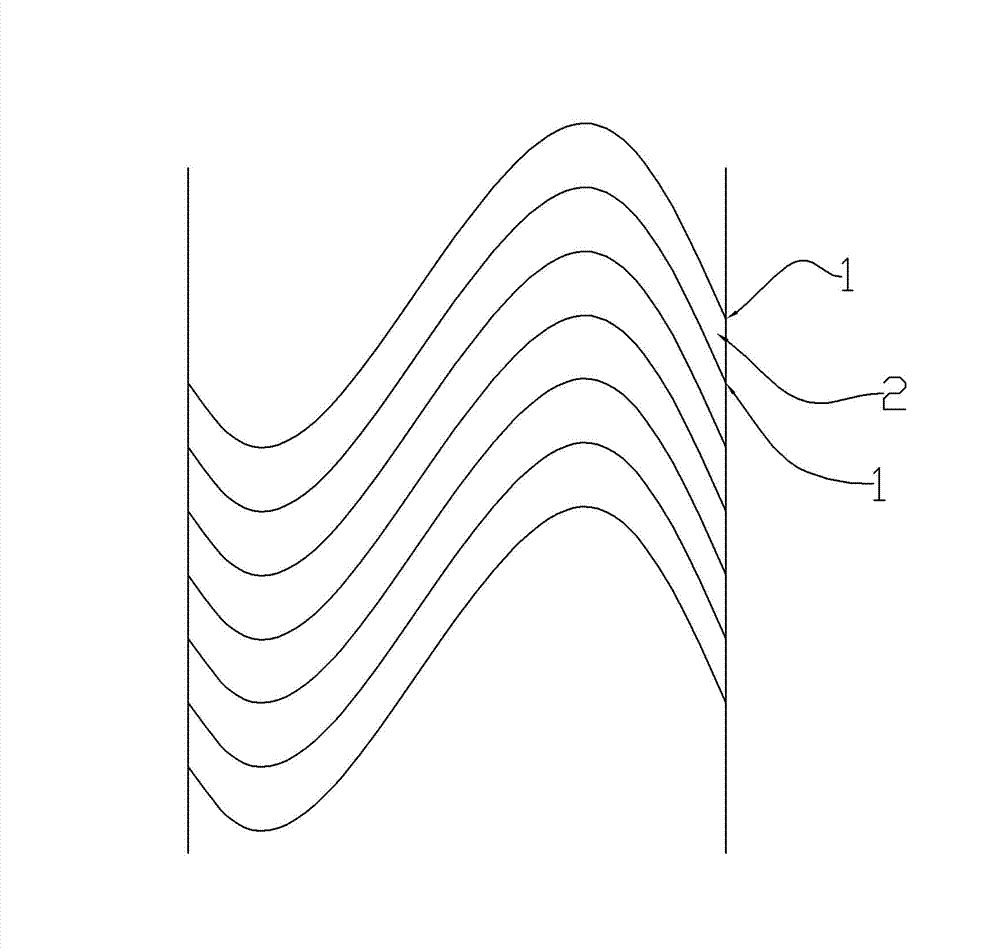

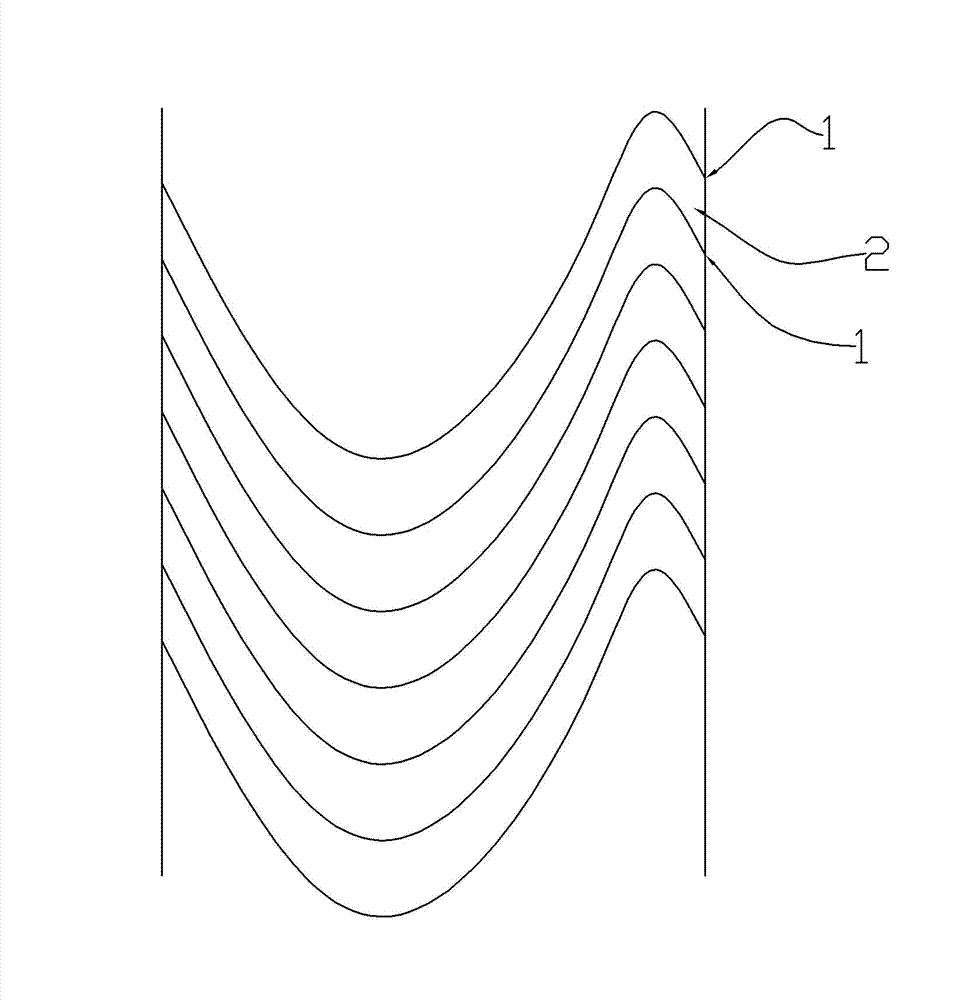

[0012] Such as figure 1 , a sound-absorbing cotton structure, including a multi-layer fiber layer 1 with a larger fiber apparent density and a fiber layer 2 with a smaller fiber apparent density, and a fiber layer 1 with a larger fiber apparent density and a fiber layer with a smaller fiber apparent density The fiber layers 2 are stacked staggeredly, and the fiber layer with higher fiber apparent density is S-shaped.

[0013] The crest and trough positions of the S-shaped structure of each S-shaped fiber layer can be consistent, such as figure 1 , figure 2 . The peaks and troughs of the S-shaped structure of each S-shaped fiber layer are evenly distributed in the same size, such as figure 1 . It can also have small troughs and large peaks, such as figure 2 . It is also possible to have large troughs and small peaks, such as image 3 .

[0014] The crests and troughs of the S-shaped structure of each S-shaped fiber layer can also be misplaced to form S-shaped fiber la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com