Directional coupler

A directional coupler and electromagnetic coupling technology, applied in waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of increased coupling, power fluctuations, and uneven amplitude characteristics of coupled signals, and achieve a near-flat amplitude characteristic. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

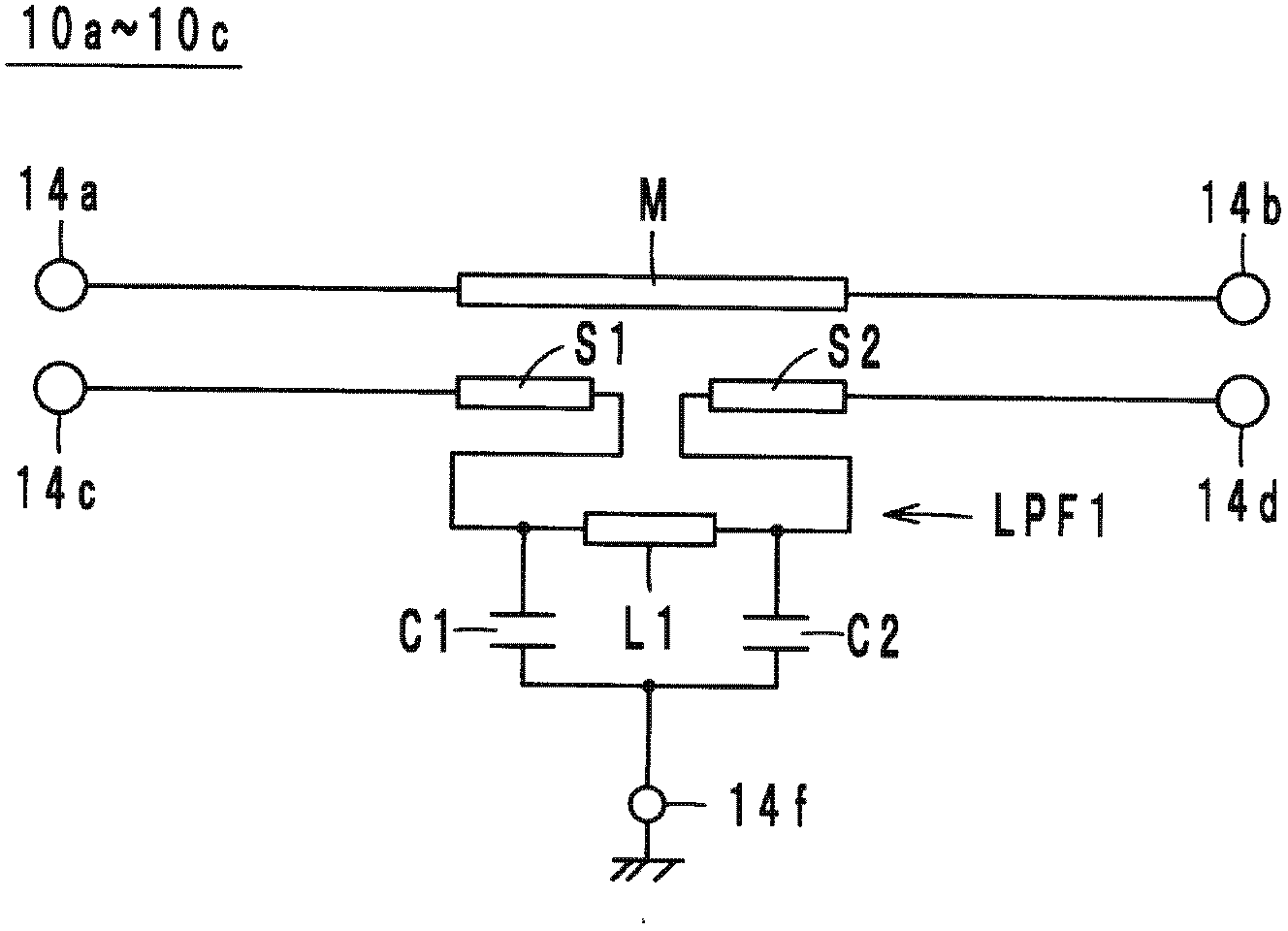

[0023] Next, the directional coupler according to Embodiment 1 will be described with reference to the drawings. figure 1 It is an equivalent circuit diagram of the directional couplers 10 a to 10 c according to Embodiment 1 to Embodiment 3. FIG.

[0024] The circuit configuration of the directional coupler 10a will be described. The directional coupler 10a is used for a predetermined frequency band. For example, when a signal having a frequency band of 824 MHz to 915 MHz (GSM800 / 900) and a signal having a frequency band of 1710 MHz to 1910 MHz (GSM1800 / 1900) are input to the directional coupler 10a, the predetermined frequency refers to 824 MHz to 1910 MHz.

[0025] As a circuit structure, the directional coupler 10a includes external electrodes (terminals) 14a to 14f ( figure 1 The external electrode 14e), the main line M, the sub lines S1, S2, and the low-pass filter LPF1 are not shown. The main line M is connected between the external electrodes 14a, 14b. The sub-line ...

Embodiment approach 2

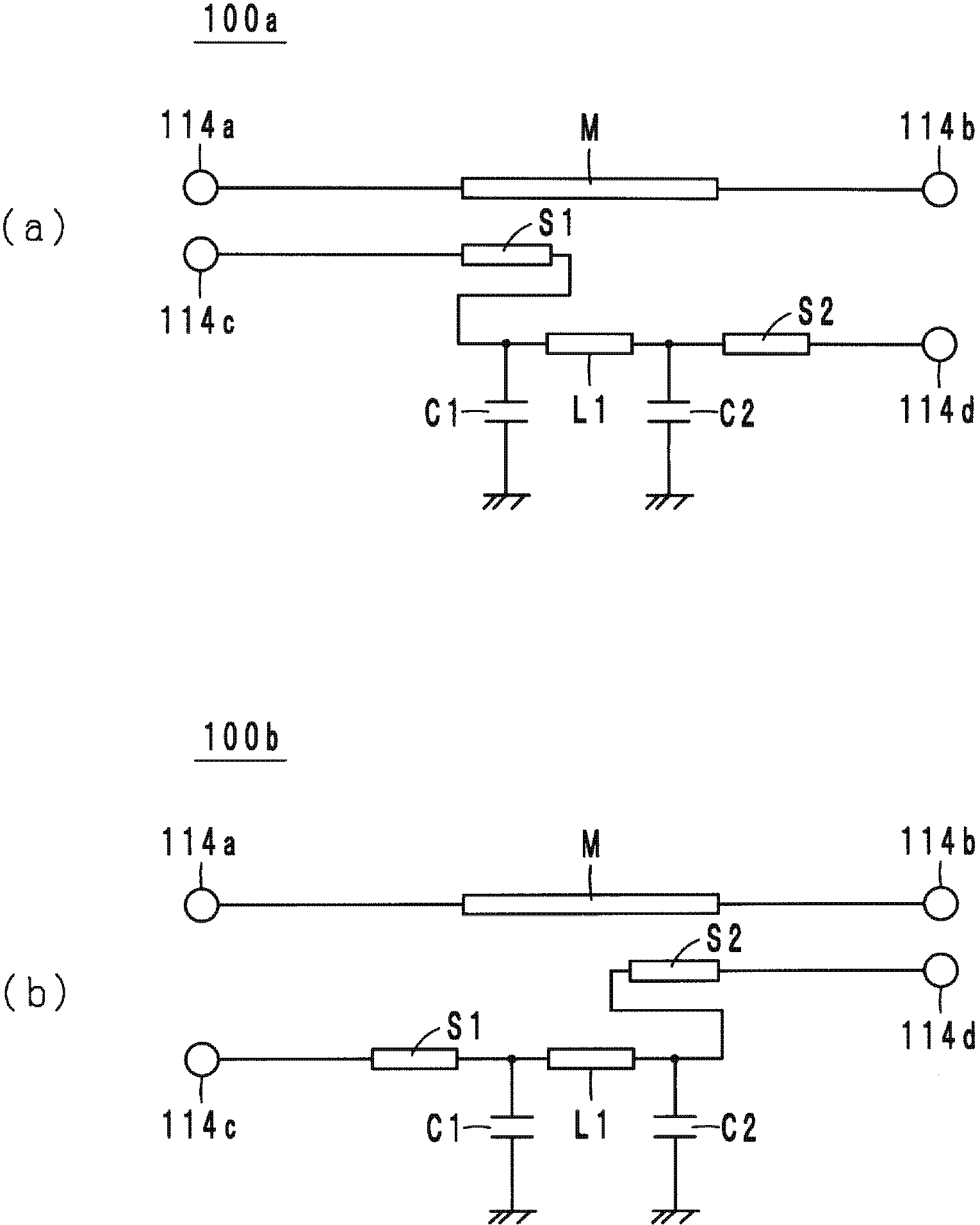

[0068] Next, the configuration of the directional coupler 10b according to Embodiment 2 will be described with reference to the drawings. Figure 10 It is an exploded perspective view of the laminated body 12b of the directional coupler 10b according to the second embodiment.

[0069] Since the circuit configuration of the directional coupler 10b is the same as that of the directional coupler 10a, description thereof will be omitted. The directional coupler 10b differs from the directional coupler 10a in that, as Figure 10 As shown, the configuration of the main line M, the secondary lines S1, S2, the capacitors C1, C2, and the coil L1. In more detail, in the directional coupler 10a, as Figure 9 As shown, the main line M, sub-lines S1, S2, capacitors C1, C2, and coil L1 are arranged so as to be arranged sequentially from the negative direction side to the positive direction side in the z-axis direction in the above-mentioned order. On the other hand, in the directional co...

Embodiment approach 3

[0072] Next, the configuration of the directional coupler 10 c according to Embodiment 3 will be described with reference to the drawings. Figure 11 It is an exploded perspective view of a laminated body 12c of a directional coupler 10c according to the third embodiment.

[0073] Since the circuit configuration of the directional coupler 10c is the same as that of the directional couplers 10a and 10b, description thereof will be omitted. The directional coupler 10c differs from the directional coupler 10a in the arrangement of the main line M, the sub lines S1, S2, and the low-pass filter LPF1. In more detail, in the directional coupler 10c, as Figure 11 As shown, the main line M, the sub-lines S1, S2, and the low-pass filter LPF1 are arranged along the x-axis direction. Accordingly, in the directional coupler 10c, it is possible to reduce the height of components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com