Parallel hybrid excitation brushless direct-current motor

A brushed DC motor and hybrid excitation technology, applied in the shape/style/structure of electrical components, electromechanical devices, winding conductors, etc., to achieve efficient superposition and adjustment, simple and reliable rotor structure, and high electrical excitation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

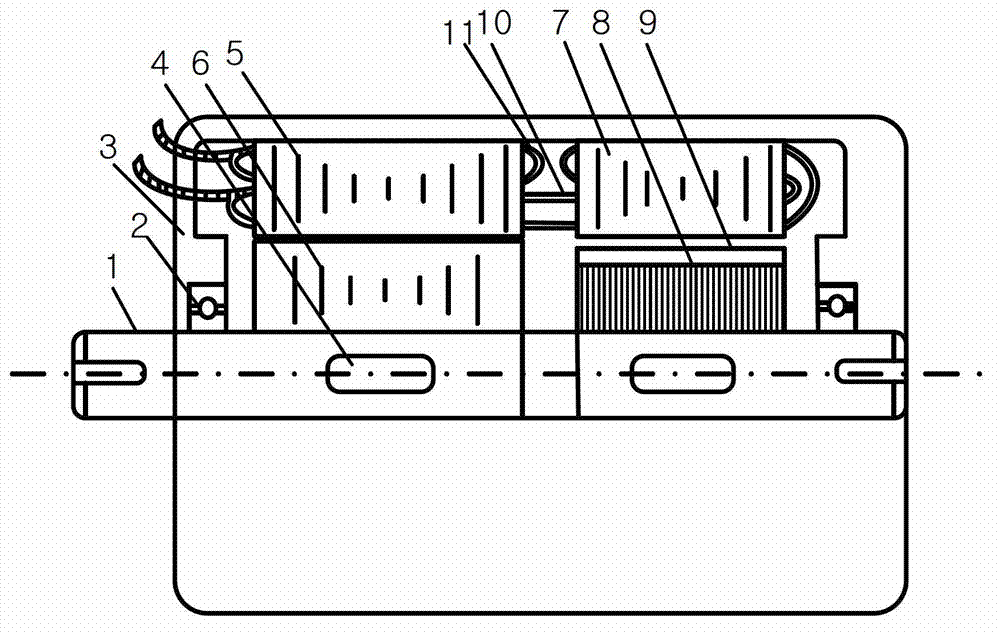

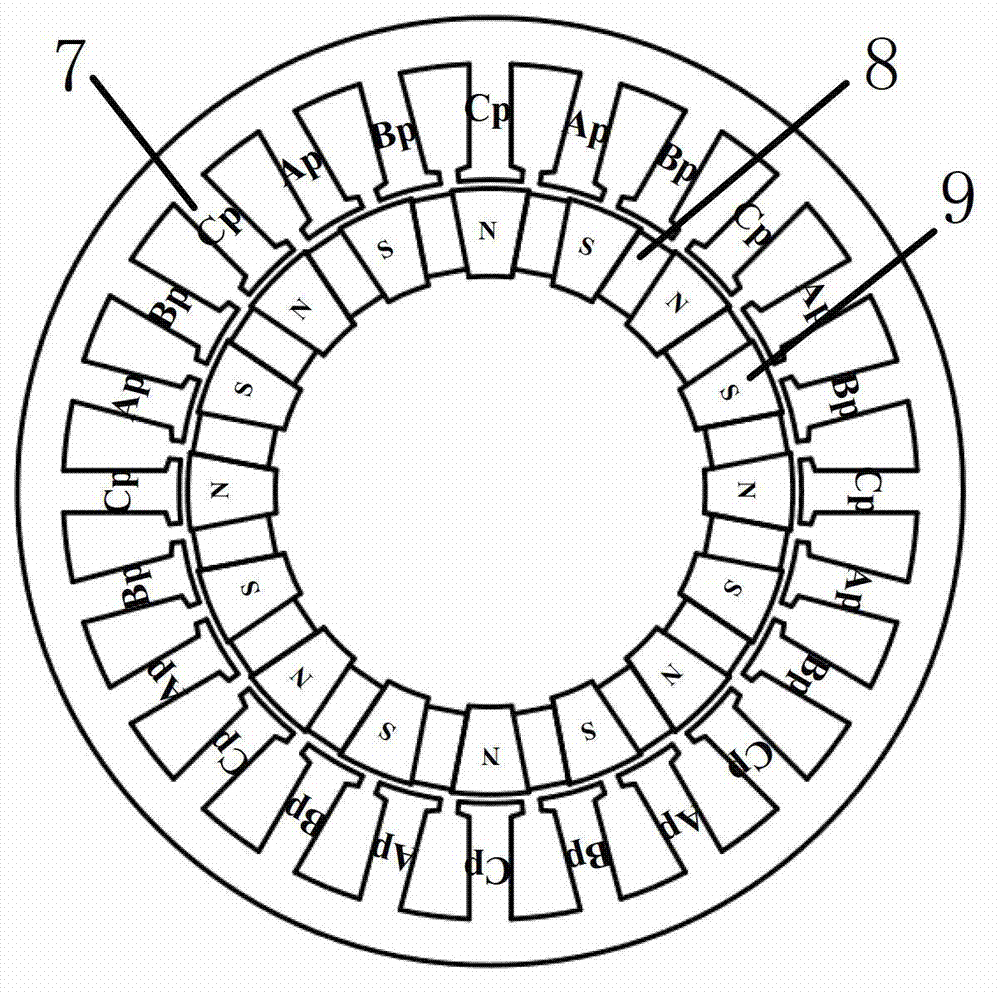

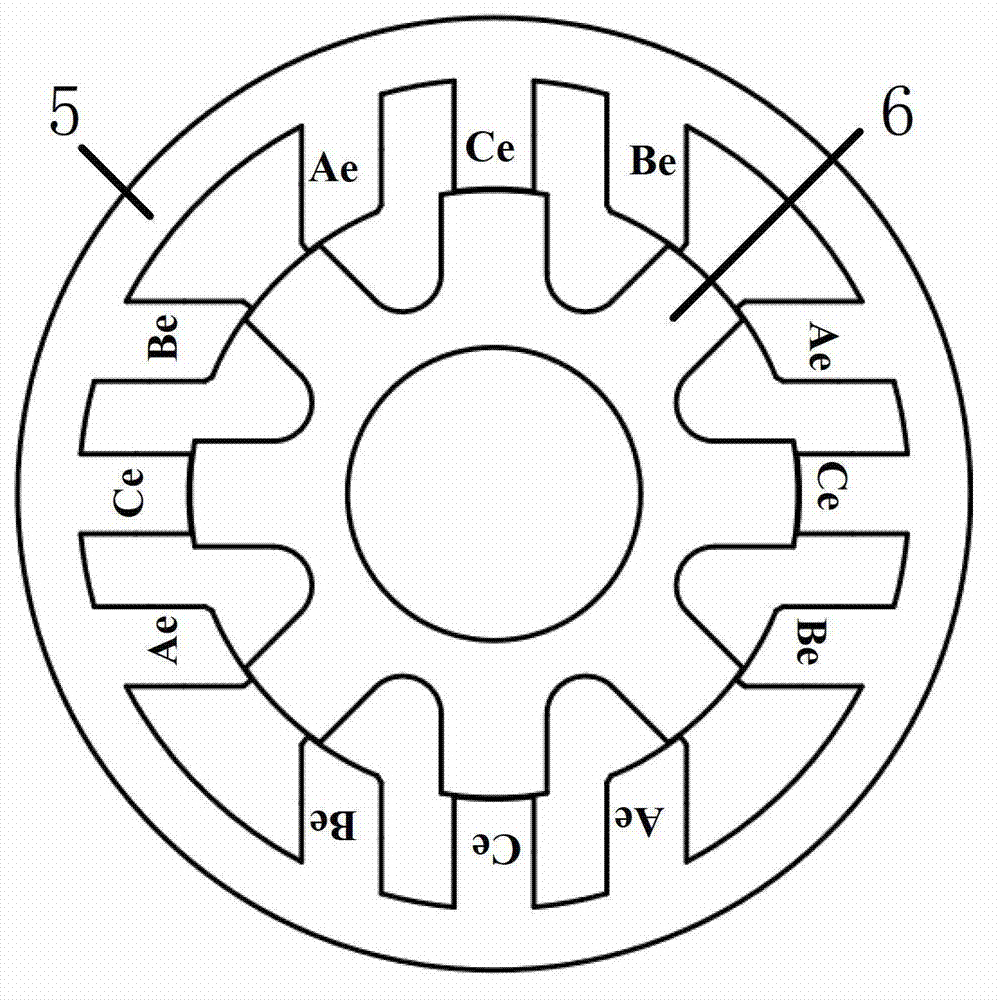

[0029] Such as figure 1 As shown, the present invention provides a parallel hybrid excitation brushless DC motor, including a casing and an electric excitation double salient motor part and a permanent magnet synchronous motor part installed in the casing, a permanent magnet synchronous motor part and an electric excitation double The salient pole motor parts are respectively installed on the left and right sides inside the casing 3 . Among them, the permanent magnet 8 is embedded in the rotor of the permanent magnet synchronous motor part, the rotor core 9 of the permanent magnet synchronous motor part and the rotor core 6 of the electric excitation double salient pole motor part are installed on the rotating shaft 1, fixed by the keyway 4, and the bearing 2 supports the rotating shaft 1 to realize the coaxial rotation of the two, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com