Simple motor gear identification method and device based on potential transformation technology

A technology of voltage mutual inductance and identification method, which is applied to devices using electric/magnetic methods, motor control, AC motor control, etc., can solve problems such as troublesome maintenance of circuit boards, low degree of equipment integration, waste of construction materials, etc., and achieve effective Facilitate popularization, reduce application cost, and reduce construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

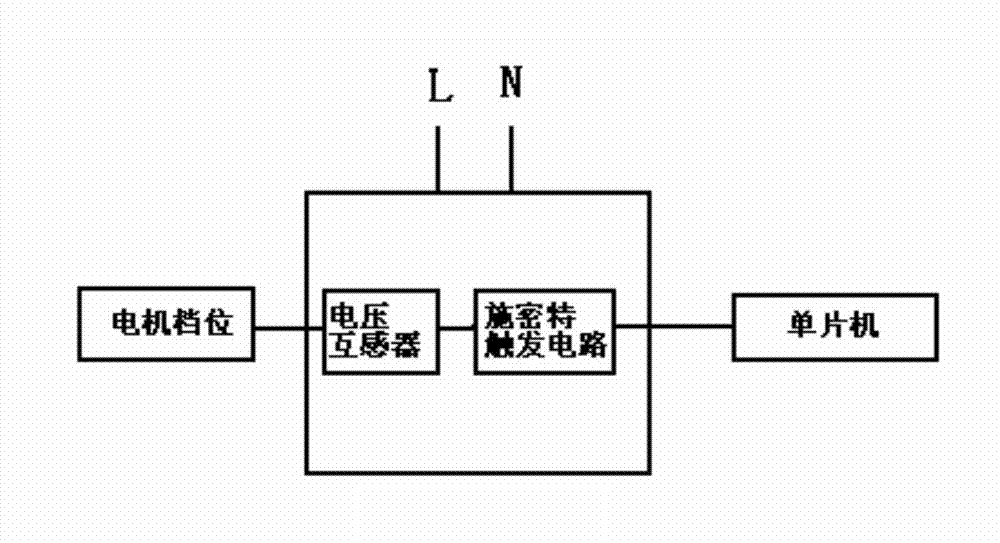

[0033] Embodiment one: see figure 1 , the present invention is based on the simple motor gear recognition method of voltage mutual induction technology, for the common zero winding multi-tap motor, by measuring the voltage induction pulse of any gear, and then according to the size of the voltage induction pulse duty cycle, compared with the standard The duty cycle is compared to determine the gear of the motor:

[0034] Based on the correction value of the induction pulse duty ratio ±0~N of any gear of the mains or fan, the high-grade is marked as K1, the middle-range is marked as K2, the mains is marked as K3, and the low-range is marked as K4, where K4> K3>K2>K1, said N is a positive real number;

[0035] Measure the induction pulse duty ratio K of the low gear of the motor. When K≤K3, it is judged that the motor is running at a low gear; when K3

Embodiment 2

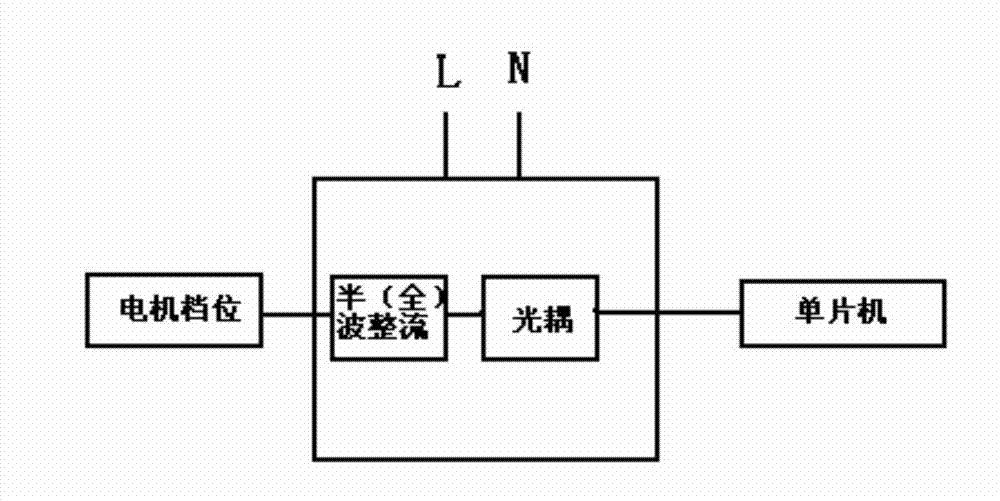

[0036] Embodiment two: see figure 2 , this embodiment is based on the simple motor gear identification method based on voltage mutual induction technology. The difference from Embodiment 1 is that the gear position of the motor is determined by measuring the duty cycle of the induction pulse of the gear position in the motor and comparing it with the standard duty cycle. :

[0037] Based on the correction value of the induction pulse duty ratio ±0~N of any gear of the mains or fan, the high-grade is marked as K1, the middle-range is marked as K2, the mains is marked as K3, and the low-range is marked as K4, where K4> K3>K2>K1, said N is a positive real number;

[0038]Measure the induction pulse duty ratio K of the middle gear of the motor. When K≤K2, it is judged that the motor is running at a low gear; when K2

Embodiment 3

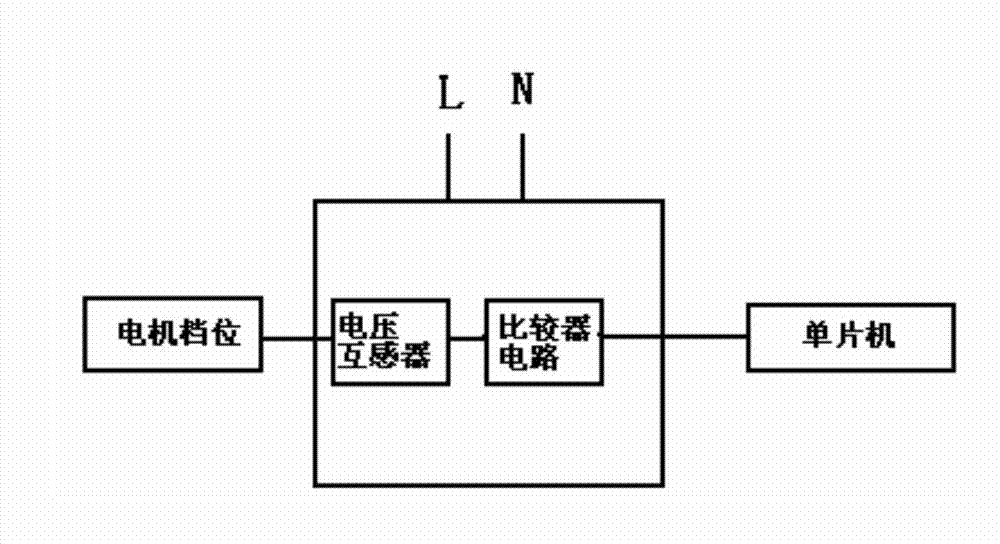

[0039] Embodiment three: see image 3 , this embodiment is based on the simple motor gear identification method based on voltage mutual induction technology. The difference from Embodiment 1 is that the gear position of the motor is determined by measuring the duty cycle of the induction pulse of the gear position in the motor and comparing it with the standard duty cycle. :

[0040] Based on the correction value of the induction pulse duty ratio ±0~N of any gear of the mains or fan, the high-grade is marked as K1, the middle-range is marked as K2, the mains is marked as K3, and the low-range is marked as K4, where K4> K3>K2>K1, said N is a positive real number;

[0041] Measure the induction pulse duty cycle K of the high gear of the motor. When K≤K1, it is determined that the motor is running at a low gear; when K1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com