Motor gear identification method and device

An identification method and identification device technology, applied in the direction of motor generator testing, etc., can solve the problems of troublesome maintenance of circuit boards, low equipment integration, waste of construction materials, etc., to facilitate popularization, realize multi-port acquisition, and reduce construction difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

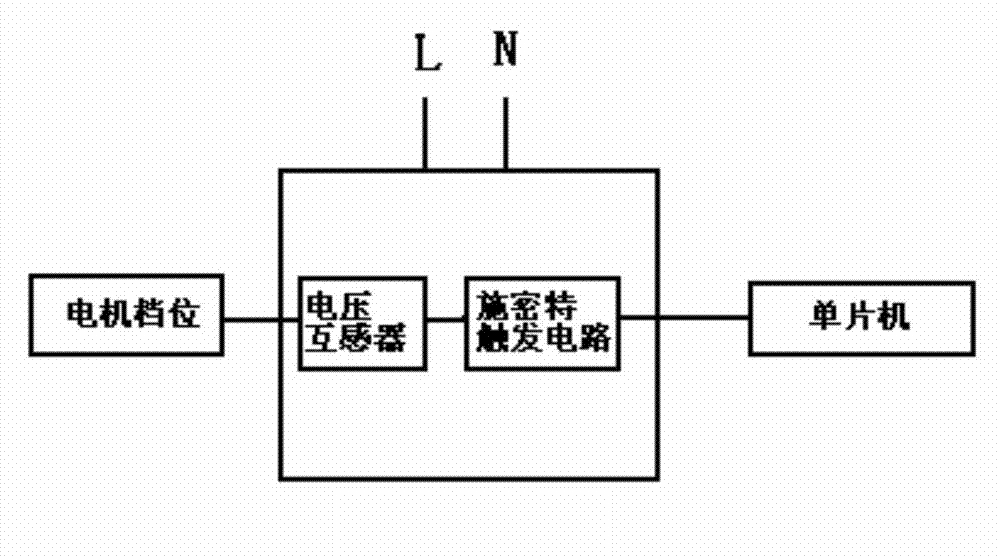

[0033] Embodiment one: see figure 1 , the motor gear identification method of the present invention, for a common zero winding multi-tap motor, by measuring the voltage induction pulse of any gear, and then according to the size of the voltage induction pulse width, compared with the standard pulse width, determine the motor stalls:

[0034] Based on the correction value of the induction pulse width ±0~N of any gear of the mains or fan, the high-grade is recorded as K1, the middle-range is K2, the mains is K3, and the low-grade is K4, where K4>K3> K2>K1, said N is a positive real number;

[0035] Measure the induction pulse width K of the low gear position of the motor. When K≤K3, it can be judged that the motor is running at a low gear position; when K3

Embodiment 2

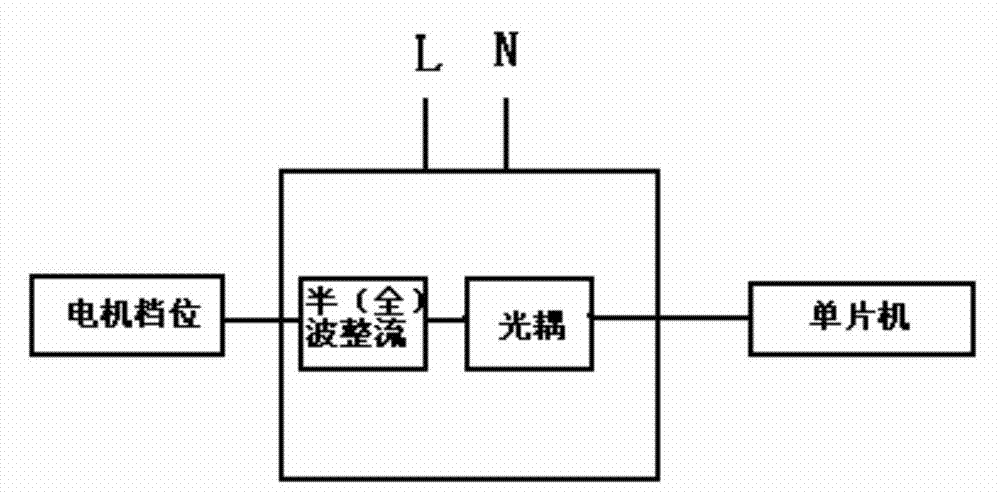

[0036] Embodiment two: see figure 2 , the motor stall identification method of this embodiment is different from Embodiment 1 in that by measuring the induction pulse width of the stall in the motor and comparing it with the standard pulse width, the stall of the motor is determined:

[0037] Based on the correction value of the induction pulse width ±0~N of any gear of the mains or fan, the high-grade is recorded as K1, the middle-range is K2, the mains is K3, and the low-grade is K4, where K4>K3> K2>K1, said N is a positive real number;

[0038] Measure the induction pulse width K of the middle gear of the motor. When K≤K2, it is judged that the motor is running at a low gear; when K2

Embodiment 3

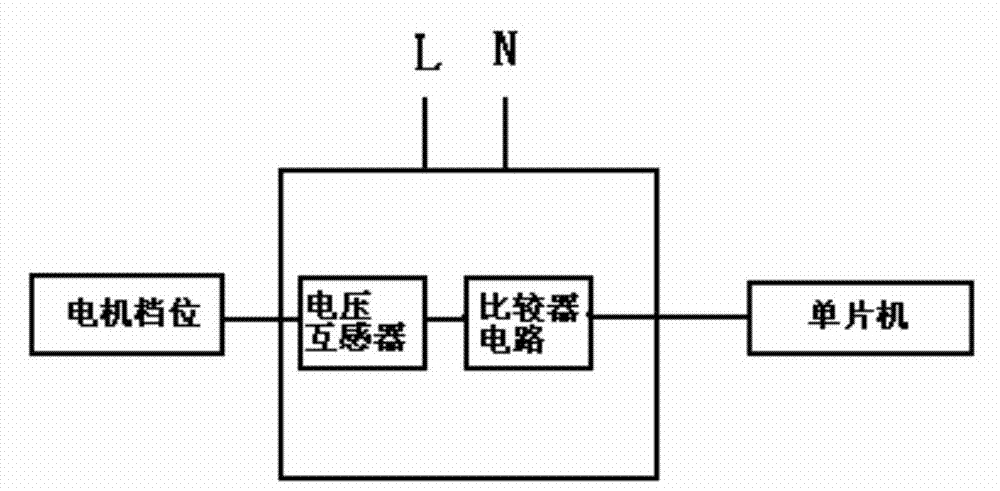

[0039] Embodiment three: see image 3 , the motor stall identification method of this embodiment is different from Embodiment 1 in that by measuring the induction pulse width of the stall in the motor and comparing it with the standard pulse width, the stall of the motor is determined:

[0040] Based on the correction value of the induction pulse width ±0~N of any gear of the mains or fan, the high-grade is recorded as K1, the middle-range is K2, the mains is K3, and the low-grade is K4, where K4>K3> K2>K1, said N is a positive real number;

[0041] Measure the induction pulse width K of the high gear of the motor. When K≤K1, it is judged that the motor is running at a low gear; when K1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com