Self-tightening type packing box seal displacement buffer, and loop reactor

A technology of stuffing box and buffer, which is applied in the direction of engine sealing, chemical instruments and methods, engine components, etc. It can solve the problems of reduced sealing performance, slightly poor sealing performance, and the dynamic sealing function of packing can not be well exerted, etc. , to achieve the effect of high sealing reliability and good self-tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

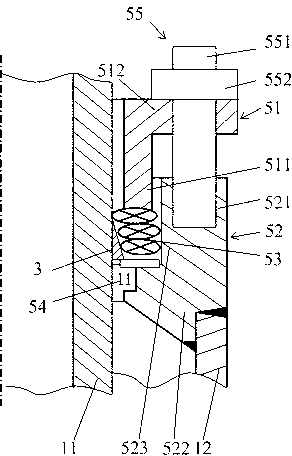

[0041] A specific embodiment of a self-tightening stuffing box seal displacement buffer of the present invention, as figure 2 As shown, it includes a packing compression ring 51, a sealing letter 52, a packing 53, a rubber sealing ring 54 and a fastener 55. The packing compression ring 51 and the sealing box 52 cooperate with each other. One section compresses the gap between the inner side 523 of the sealing box 52 and the outer wall surface of the inner pipe 11 by compressing the packing 53, and the other section of the packing pressure ring 51 is connected to the seal by the fastener 55. The sealing box 52 is connected with the outer tube 12, and the rubber sealing ring 54 is arranged in the gap between the inner side 523 of the sealing box 52 and the outer wall surface of the inner tube 11, and is located in the packing 53 , which also includes an inclined sealing body 3 , the inclined sealing body 3 is connected to the outer wall surface of the inner pipe 11 , and the ou...

Embodiment 2

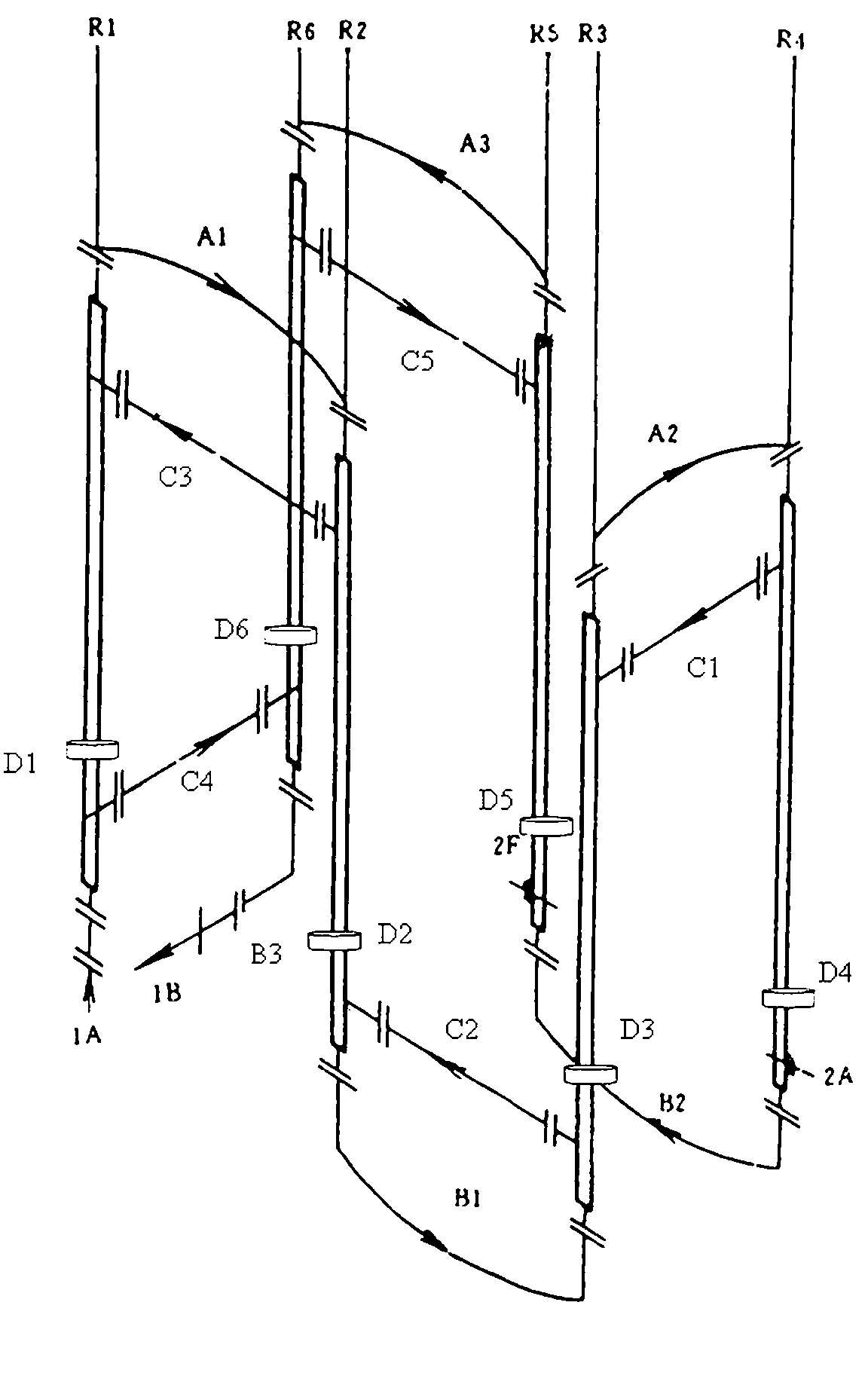

[0052] A specific embodiment of a loop reactor of the present invention includes a straight casing, a jacket connecting pipe, an elbow and a mounting support, the straight casing includes an inner pipe 11 and an outer pipe 12, and the elbow The head and the inner pipe 11 are sequentially connected in series to form a communication channel for conveying and reacting the reaction material. The jacket flow channel formed between the outer tubes 12 is connected in series to form a communication channel for conveying cooling medium, and the mounting support is arranged at the lower part of the outer tube 12 so that the straight sleeve is divided into the upper pipe section of the straight sleeve and the straight sleeve. The lower pipe section of the casing, the straight casing is provided with a displacement buffer between the inner pipe 11 and the outer pipe 12 for absorbing the thermal expansion and contraction displacement between the inner pipe 11 and the outer pipe 12 The disp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap