Adjustable cleaning clamp

A cleaning fixture and to-be-cleaned technology, applied in the field of lens cleaning, can solve the problems of high cost, unfavorable cleaning, and large contact area between the lens and the groove, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

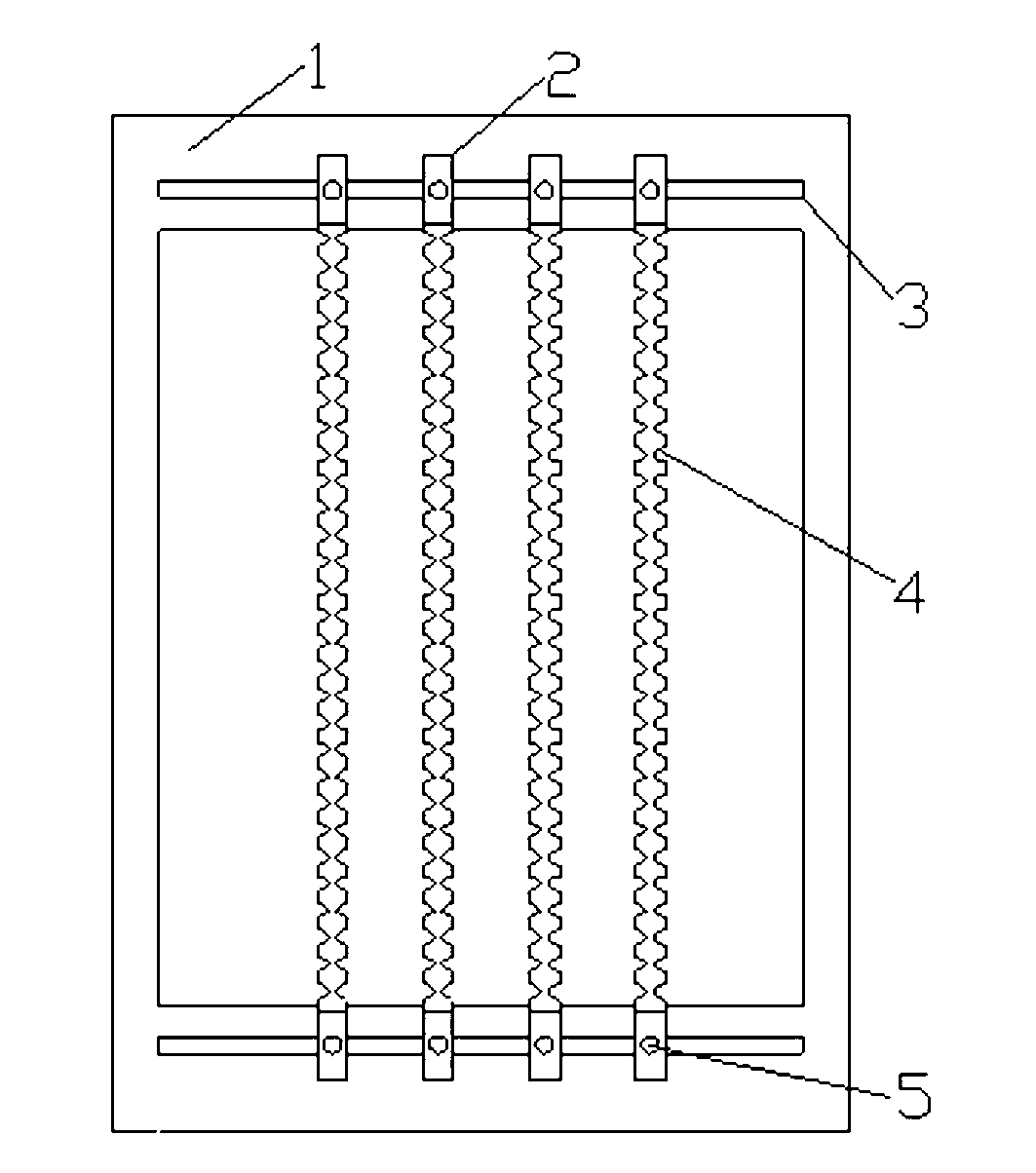

[0013] As shown in the drawings, the adjustable cleaning fixture includes a bottom frame 1 and four clamping bars 2 arranged in parallel. There are through grooves 3 on two opposite sides of the bottom frame 1, and the through grooves 3 are pierced There are screws 5 to fix the two ends of the clip bar 2 on the bottom frame 1, and each clip bar 2 has a plurality of vertical grooves 4 on the two side walls, and the groove diameter of the lower part of the vertical groove 4 is smaller than that of the upper part, which is used for connecting with the bottom frame 1. The vertical grooves of the adjacent clip bars jointly support the lens to be cleaned.

[0014] When in use, according to the specifications of the lens to be cleaned, move the position of the clamp bar 2 along the through groove 3, adjust the size of the enclosed space of the vertical slot 4 of two adjacent clamp bars, then put the lens vertically, and finally place the clamp flat It can be cleaned after entering th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com