Integral sliding plate structure of motor seat, front support and rear support of lead screw and nut seat of lead screw

A technology of screw nut seat and screw nut, which is applied to metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problem of inconsistent positioning benchmarks for parts machining, affecting the structural accuracy of the skateboard, and difficult to guarantee technical parameters. and other problems, to achieve the effect of shortening product production cycle, small vibration, and reducing the number of clamping times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

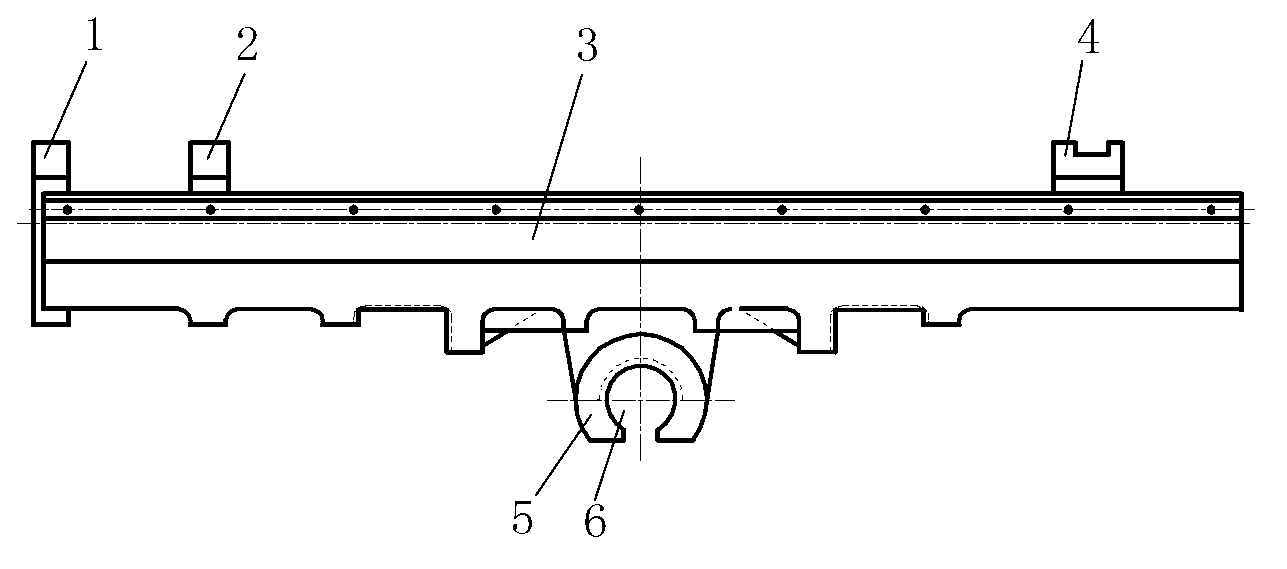

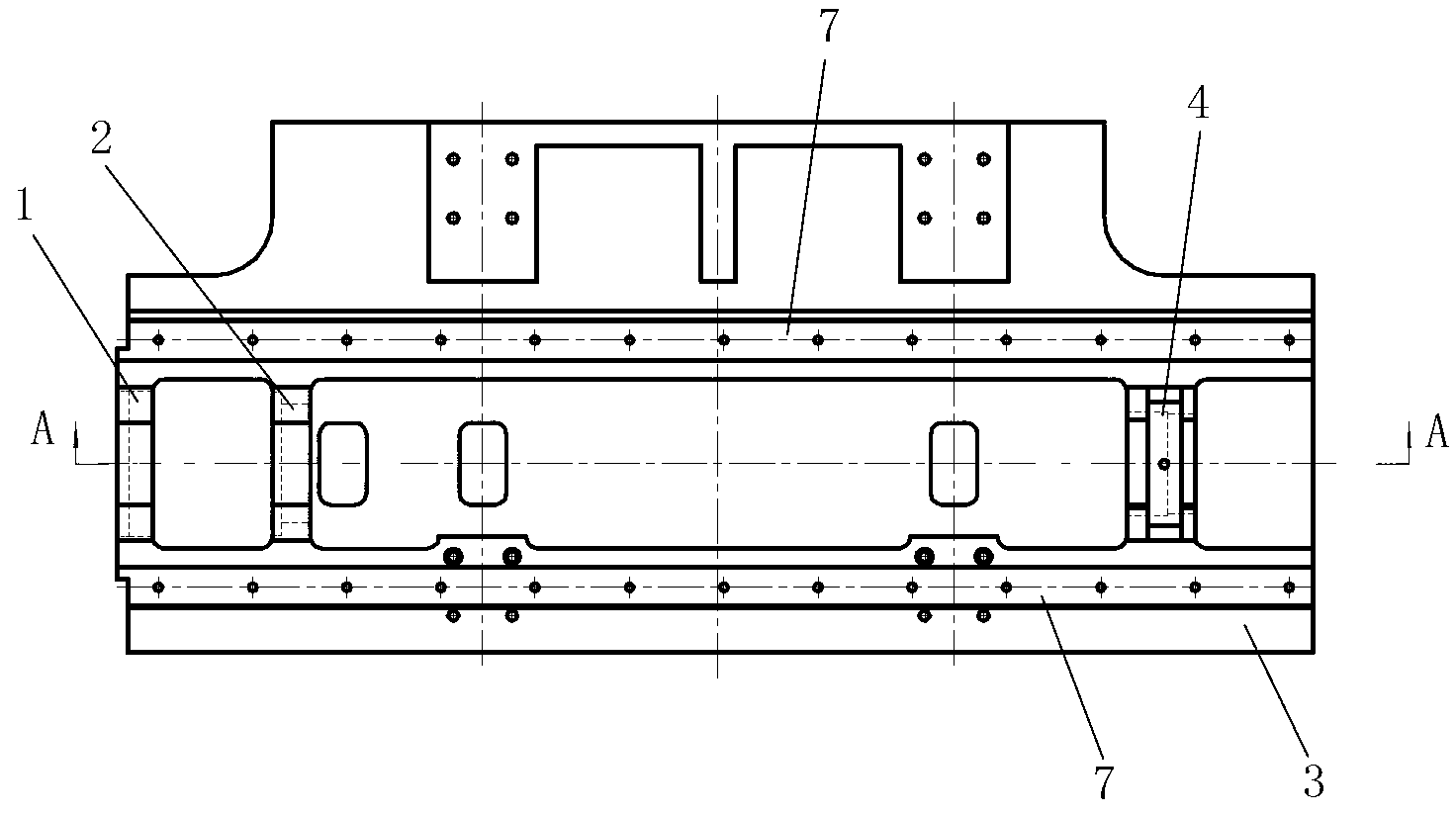

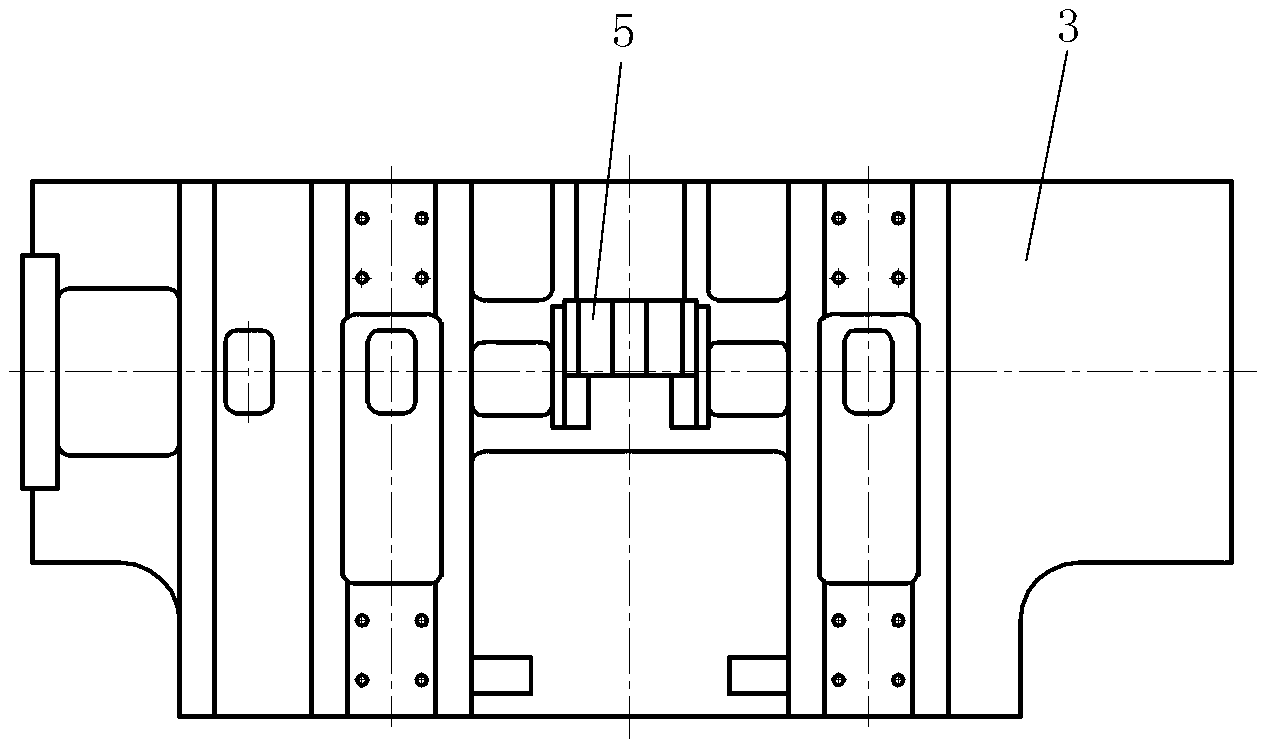

[0015] Such as Figure 1 to Figure 6 As shown, the integrated skateboard structure of the motor seat, the front and rear supports of the screw rod, and the screw nut seat of the present invention includes the main body of the skateboard 3, the motor seat 1, the front support of the screw rod 2, the rear support of the screw mandrel 4, and the screw nut seat 5. The skateboard main body 3, motor seat 1, screw front support 2, screw rear support 4, and screw nut seat 5 of the skateboard structure are an integral structure.

[0016] The front support 2 of the screw rod and the rear support 4 of the screw rod are respectively formed by extending upwards from the front end and the rear end of the main body of the slide plate 3, and the middle part of the front support 2 of the screw rod is provided with an inner hole of the front support which runs through the front support 2 of the screw mandrel. 10. The middle part of the rear support 4 of the screw rod is provided with a rear sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com