Vertical slide platform

A sliding table and sliding seat technology, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of large occupied space, danger, and many metal materials, and achieve small space and low material consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

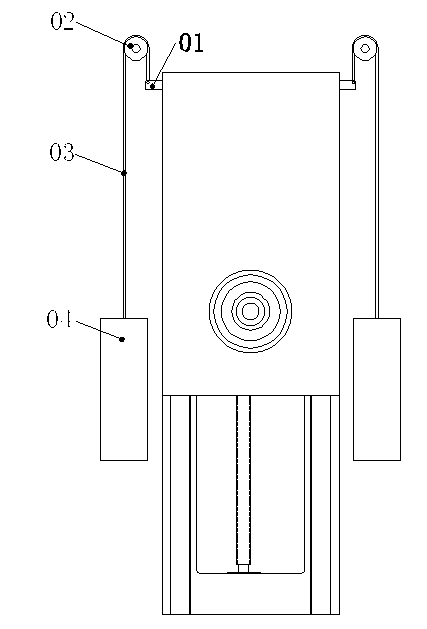

Image

Examples

Embodiment Construction

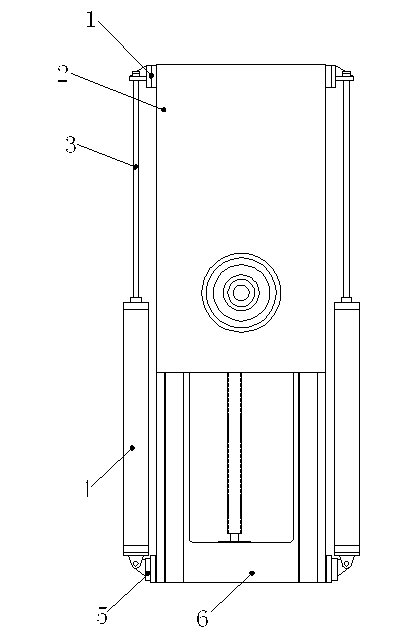

[0013] figure 2 Among them, the cylinder shaft connecting seat 1 is installed on the sliding table 2, the cylinder shaft 3 of the cylinder is installed on the cylinder shaft connecting seat 1, the cylinder barrel 4 of the cylinder is installed on the cylinder barrel connecting seat 5, and the cylinder barrel connecting seat 5 is installed on the sliding seat 6 on. The number of cylinders is not limited to the number shown in the figure, and may be more than one cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com