Slip ring grinding machine of high-power motor rotor

A motor rotor and grinder technology, which is applied to grinders, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problems of reduced slip ring insulation, increased carbon powder, and increased maintenance costs, so as to improve grinding efficiency, improve grinding quality and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

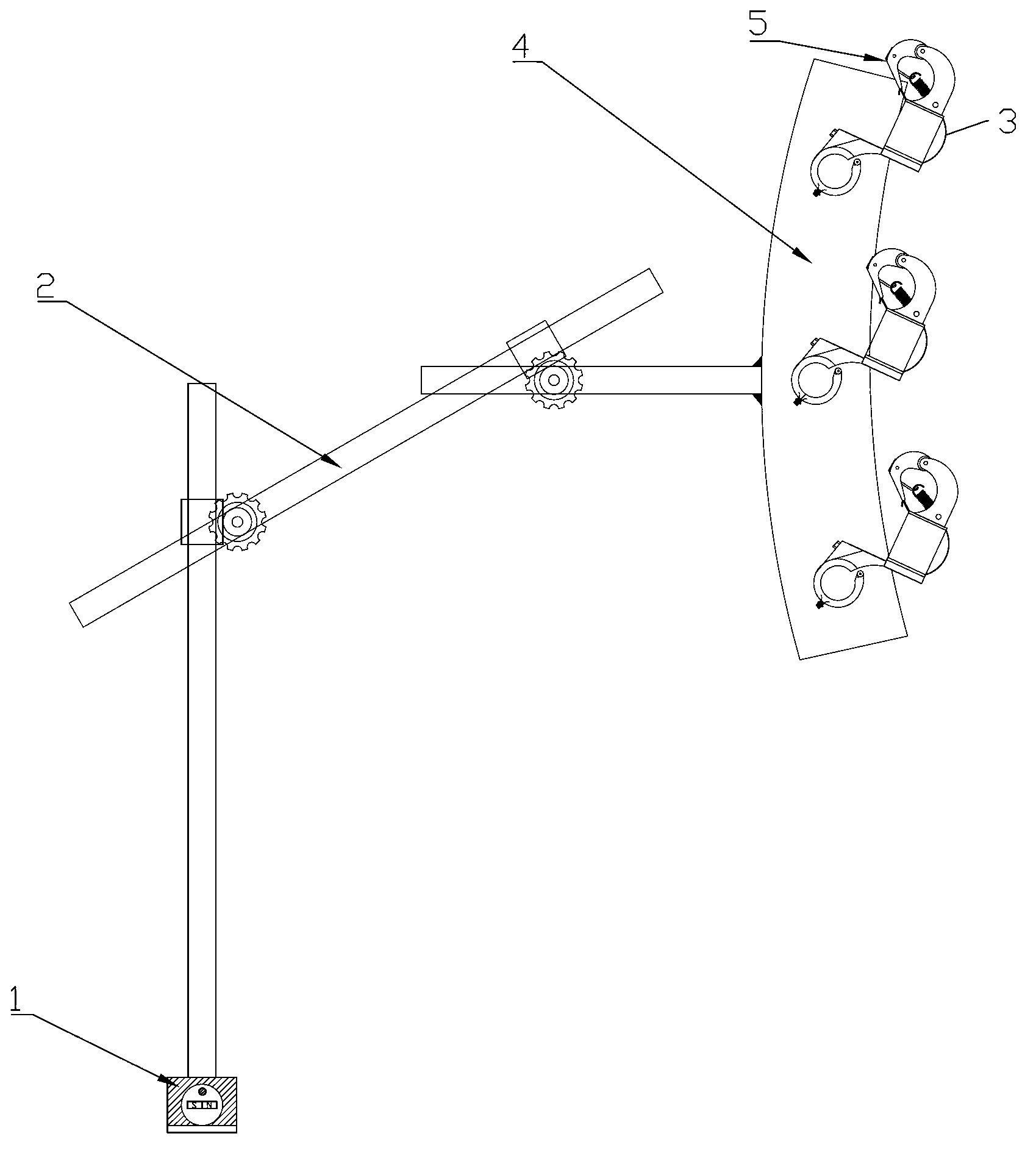

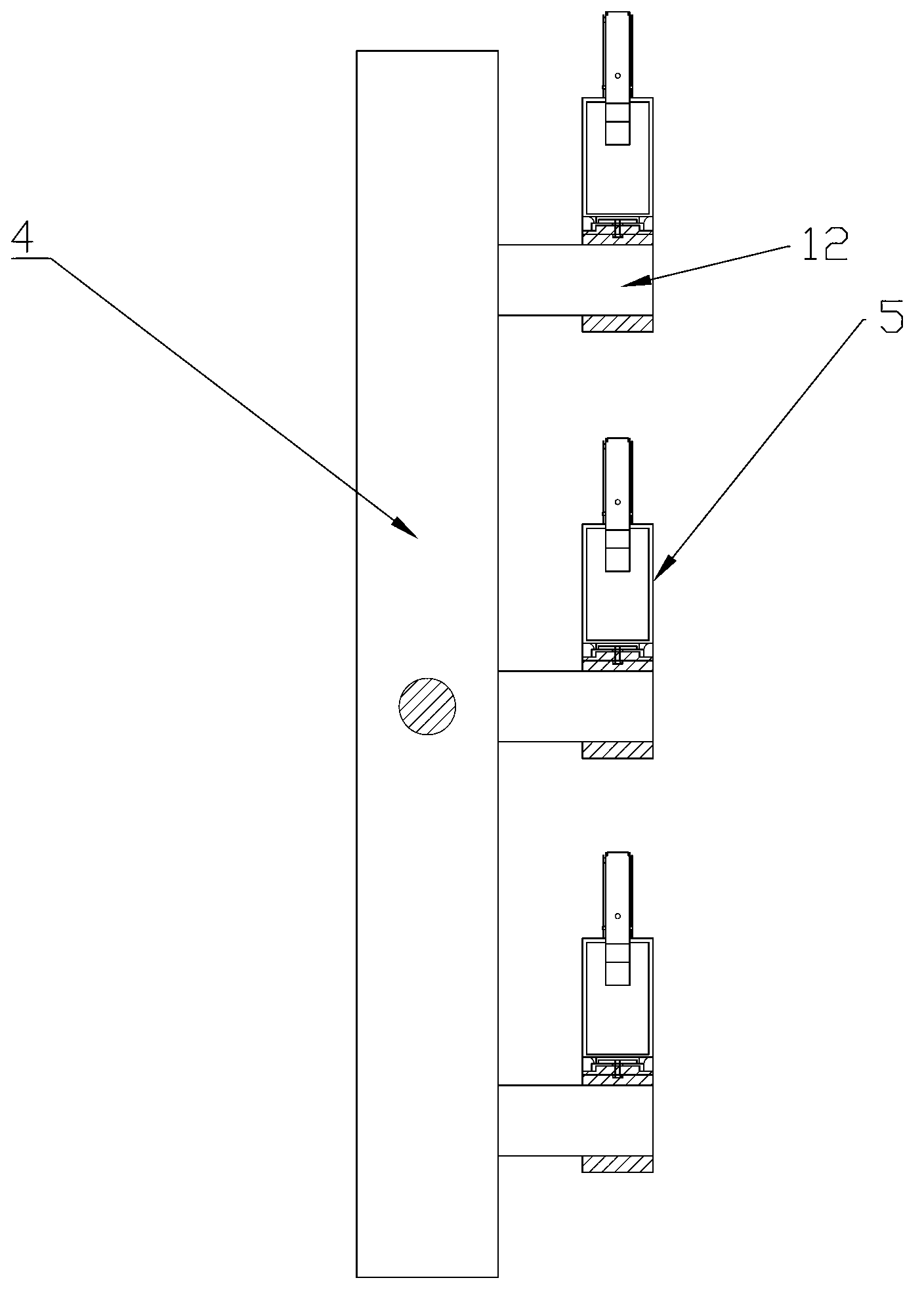

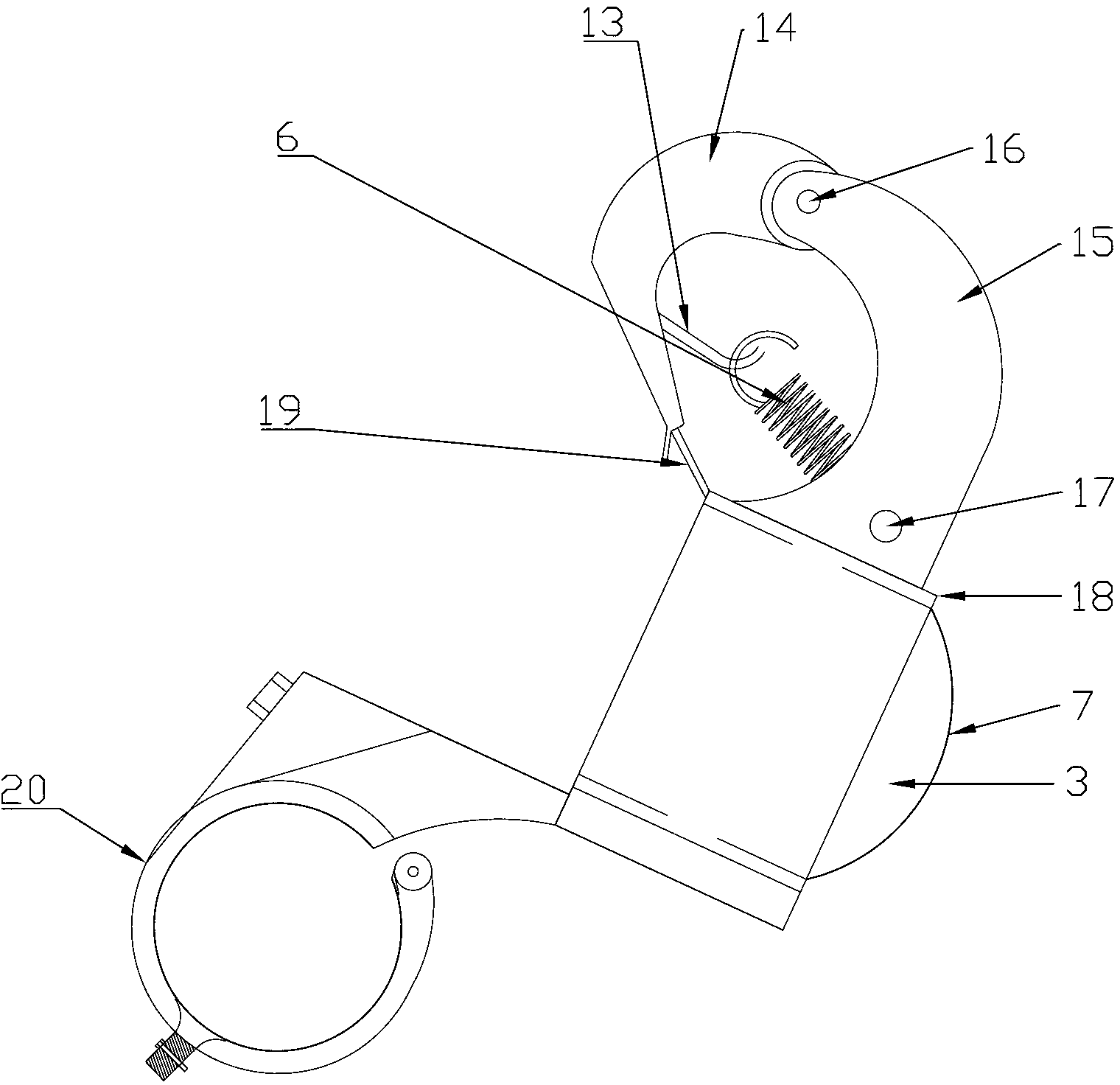

[0025] Such as Figure 1-5 As shown, the high-power motor rotor slip ring dresser of the present invention includes a magnetic base 1, a Vientiane support arm 2, and a grinding stone 3. One end of the Vientiane support arm 2 is fixed on the magnetic base 1, and on the Vientiane support arm The end of the 2 is provided with an arc-shaped fixed bracket 4, and a plurality of grindstone holders 5 are fixed on the arc-shaped fixed bracket 4, and the grindstone holders 5 are vertically and evenly distributed along the arc-shaped fixed bracket 4, and the described grindstone 3 is set On Millstone Grip 5.

[0026] Both the Vientiane support arm 2 and the arc-shaped fixing bracket 4 are made of insulating materials. It can ensure the insulation between the slip ring and the magnetic base, and also ensure that personnel will not get an electric shock when adjusting the angle of the dresser.

[0027] There are three grindstone holders 5, which can improve the grinding efficiency. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com