Material scraping device

A technology of scraping and main shaft, which is applied to the belt-feeding device, extrusion equipment, and the field of scraping devices. It can solve the problems of increased cost of scraping devices, troublesome production and installation, and difficult cleaning of materials, so as to save replacement. Low cost, not easy to residue, clean and thorough scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

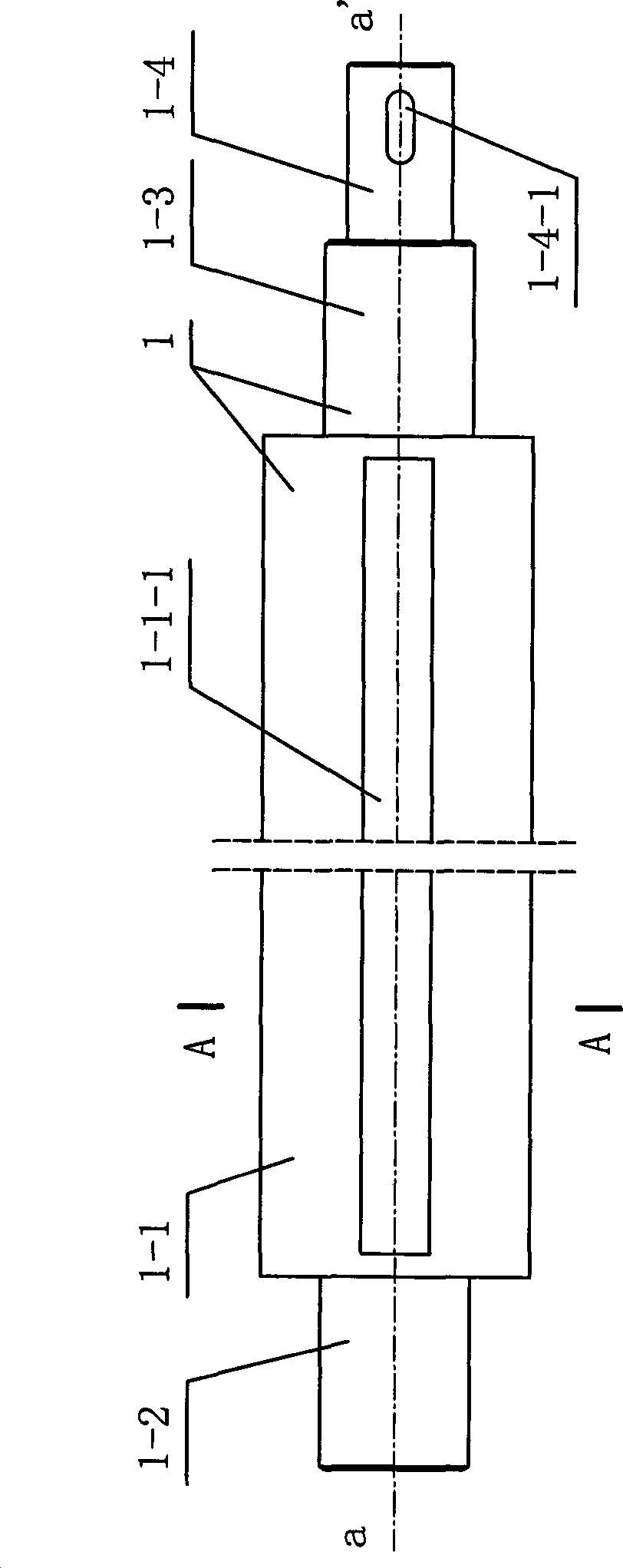

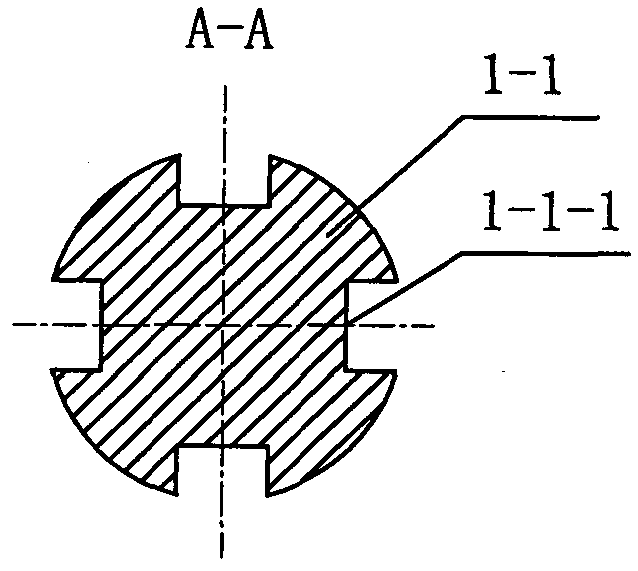

[0014] Such as figure 1 and figure 2 As shown, a scraping device includes a scraper shaft body 1, and the scraper shaft body 1 includes a scraper main shaft 1-1, and also includes a left shaft head 1-2 arranged on the left side of the scraper main shaft 1-1. And the right shaft head 1-3 arranged on the right side of the scraping main shaft 1-1, the right end of the right shaft head 1-3 is also provided with a connecting shaft head 1-4, and the connecting shaft head 1-4 has a keyway 1-4-1. A scraping groove 1-1-1 parallel to the longitudinal axis aa' is formed on the outer surface of the scraping main shaft 1-1, and the cross-sectional shape of the scraping groove 1-1-1 is groove-shaped. The scraping grooves 1-1-1 are evenly arranged on the outer surface of the scraping main shaft 1-1, and there are four scraping grooves 1-1-1. The bottom of scraper groove 1-1-1 is smooth.

[0015] In addition to the above embodiments, the number of scraping grooves 1-1-1 of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com