Roller of conveyor belt

A conveyor belt and roller technology, applied in the field of conveyor belt rollers, can solve the problems of reduced overall efficiency, inconvenient disassembly of conveyor belts, etc., and achieve the effects of convenient operation, reduced sideslip, and reduced possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

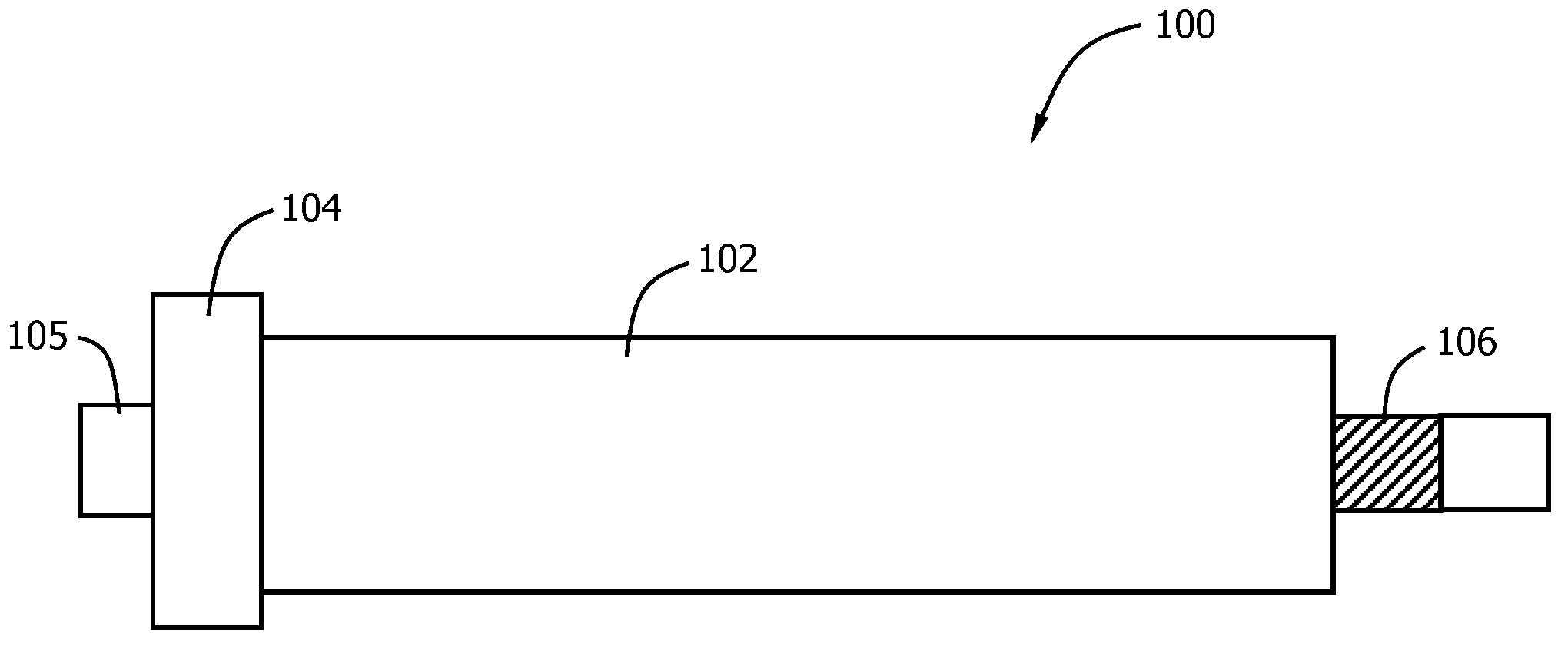

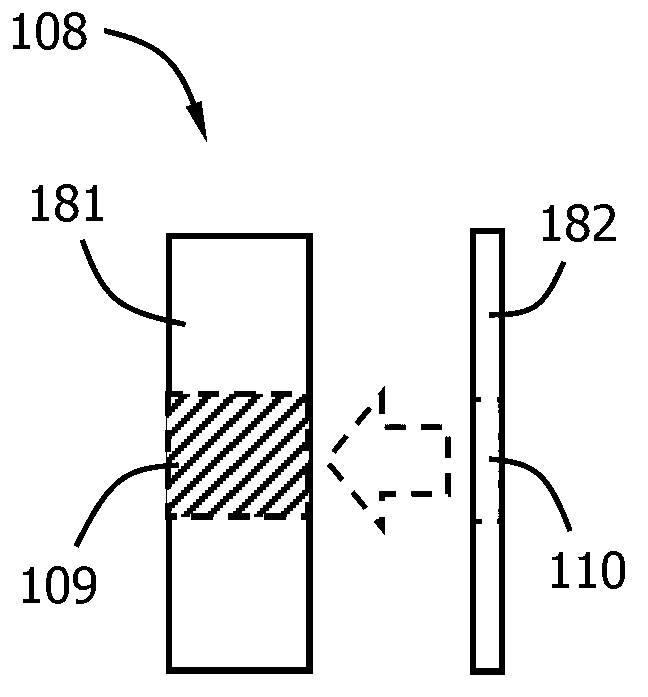

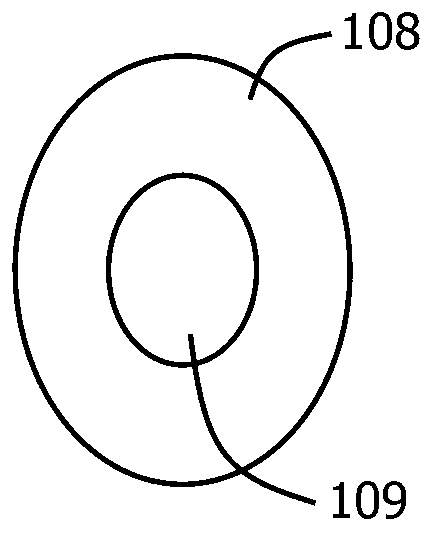

[0016] refer to figure 1 , Figure 2a and Figure 2b as shown, figure 1 , Figure 2a and Figure 2b The structure of each part in the drum according to an embodiment of the present invention is disclosed. in figure 1 revealed the structure of the barrel, Figure 2a and Figure 2b The structure of the assembly is revealed.

[0017] As shown in the figure, the roller 100 of the conveyor belt includes: a cylinder body 102 , a blocking portion 104 , a second rotating shaft 106 and an assembly 108 . The cylinder body 102 is cylindrical, and the conveyor belt is sleeved on the cylinder body 102 . The blocking portion 104 is located at a first end of the barrel 102, shown as the left end in the figure. The diameter of the blocking portion 104 is larger than that of the cylinder body 102 , and the blocking portion 104 blocks the lateral sliding of the conveyor belt sleeved on the cylinder body 102 . The blocking portion 104 extends outward to form a first rotating shaft 105...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com