Stable transmission machine

A conveyor, stable technology, applied in the field of conveyors, can solve the problems that the service life of the conveyor cannot be further improved, the impact of the hydraulic pipeline and the mechanism is large, and there is no anti-drop safety frame, etc., to achieve increased balance force and firm fixation , the effect of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

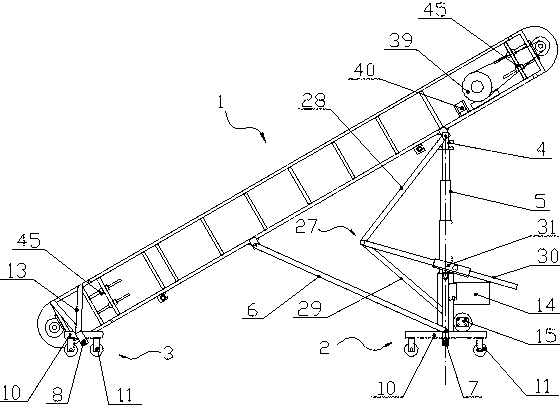

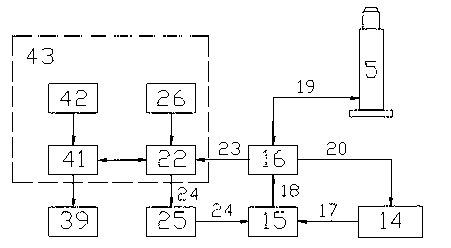

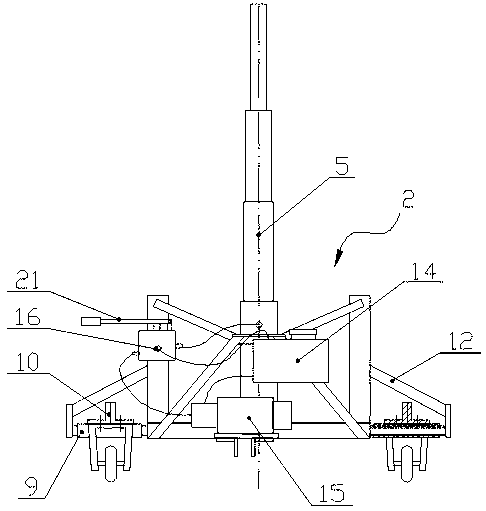

[0029] Such as figure 1 , 2Shown in and 3, a kind of smooth conveyer, comprises the conveying mechanism 1 that is coated with conveying belt, is provided with the front caster frame 2 of universal wheel and rear caster frame 3, is set on the described front caster frame 2 There is a hydraulic jack 5 supporting the bottom crossbeam 4 of the transmission mechanism, the upper end of the hydraulic jack 5 is fixedly connected to the middle part of the crossbeam 4, and the two ends of the crossbeam 4 are hinged to the frame of the transmission mechanism 1 through connecting pieces. The two sides of the front caster frame 2 and the two sides of the transmission mechanism are respectively hinged with connecting rods 6, the two sides of the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com