Method for recycling transparent conductive electrode of organic solar cell

A technology of transparent conductive electrodes and solar cells, which is applied in recycling technology, electronic waste recycling, chemical instruments and methods, etc., can solve the problems of expensive preparation costs and device performance differences, and achieve reduced surface roughness, poor stability, and combination good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

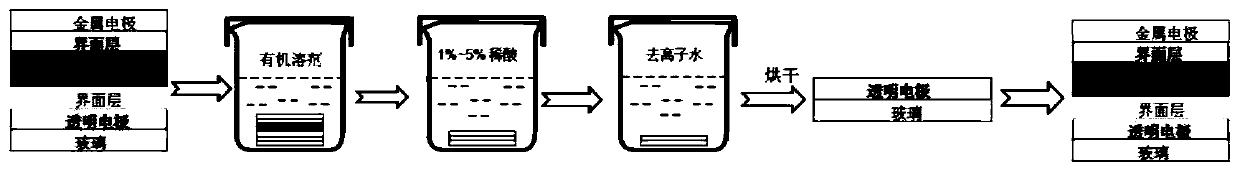

Method used

Image

Examples

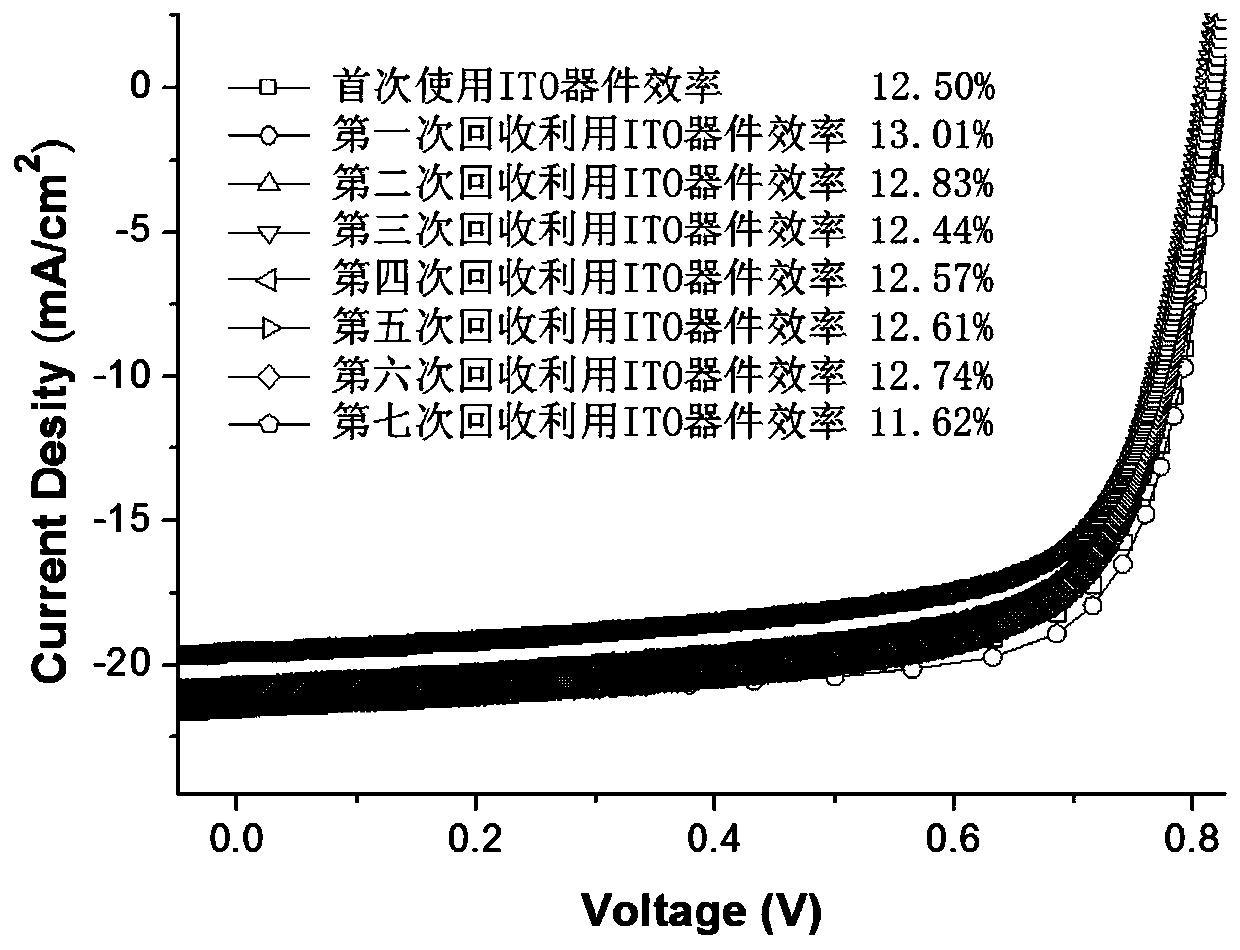

Embodiment 1

[0028] A method for recycling transparent conductive electrodes of organic solar cells is carried out as follows:

[0029] (1) Select the used ITO / ZnO / PBDB-T-2F:IT-4F / MoO 3 / Ag device is placed in chloroform solvent and oscillated under 53KHz ultrasonic conditions for 15min to fully remove the active layer PBDB-T-2F:IT-4F and the upper interface layer MoO 3 and metal top electrode Ag.

[0030] (2) Then place it in a lactic acid solution with a volume concentration of 3%, and vibrate for 15 minutes under 53KHz ultrasonic conditions to remove ZnO and residual Ag on the ITO surface.

[0031] (3) First place the recovered ITO transparent conductive electrode in deionized water containing a small amount of detergent and ultrasonically clean it for 15 minutes, then gently rub the transparent conductive electrode to remove impurities such as grease, dust, dirt and ions on the surface; Then place it in deionized water for ultrasonic cleaning for 15 minutes; then place the recovered ...

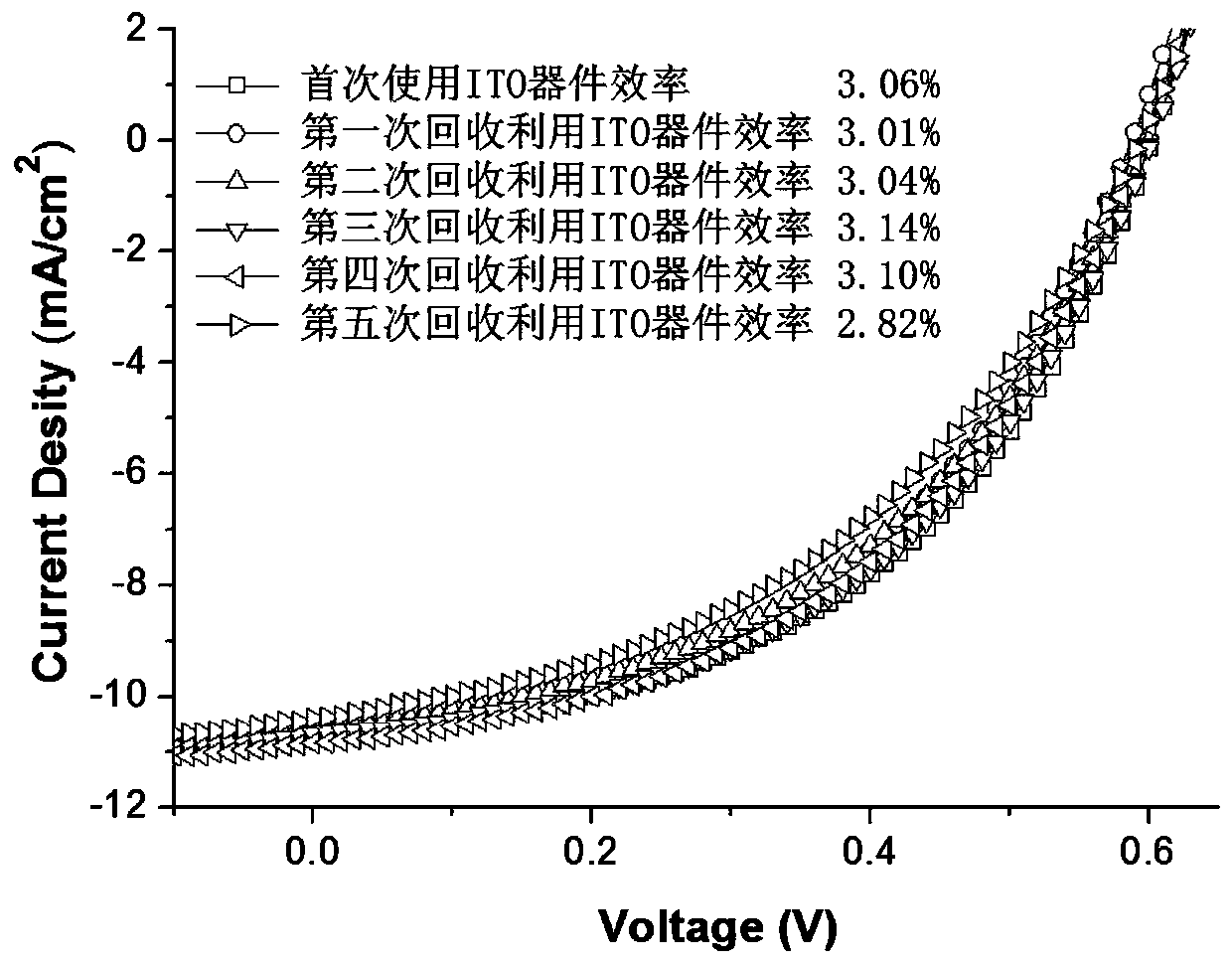

Embodiment 2

[0035]A method for recycling transparent conductive electrodes of organic solar cells is carried out as follows:

[0036] (1) Select the used FTO / PEDOT:PSS / P3HT:PCBM / LiF / Al device as the object, place it in a chlorobenzene solvent and vibrate for 20 minutes under 53KHz ultrasonic conditions, and fully remove the active layer, LiF and Al on the device ;

[0037] (2) Place in an acetic acid solution with a volume concentration of 5%, and vibrate for 15 minutes under 53KHz ultrasonic conditions to remove PEDOT:PSS and residual Al on the FTO surface.

[0038] (3) First place the recovered FTO transparent conductive electrode in deionized water containing a small amount of detergent and ultrasonically clean it for 15 minutes, then gently rub the transparent conductive electrode to remove impurities such as grease, dust, dirt and ions on the surface; Then place it in deionized water for ultrasonic cleaning for 10 minutes; then place the recovered conductive glass electrodes in acet...

Embodiment 3

[0041] A method for recycling transparent conductive electrodes of organic solar cells is carried out as follows:

[0042] (1) Select the used ITO / ZnO / CuPc:PCBM / LiF / Al device as the object, place it in a chlorobenzene solvent and vibrate for 20 minutes under 53KHz ultrasonic conditions, and fully remove the active layer, LiF and Al on the device;

[0043] (2) Place in a mixed solution of 1% acetic acid and the volume of acetic acid, vibrate for 15 minutes under 53KHz ultrasonic conditions, and perform ultrasonic treatment to remove ZnO and residual Al on the ITO surface.

[0044] (3) First place the recovered ITO transparent conductive electrode in deionized water containing a small amount of detergent and ultrasonically clean it for 10 minutes, then gently rub the transparent conductive electrode to remove impurities such as grease, dust, dirt and ions on the surface; Then place it in deionized water for ultrasonic cleaning for 15 minutes; then place the recovered conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com