Capacitive electroluminescent cold light source and its preparation method

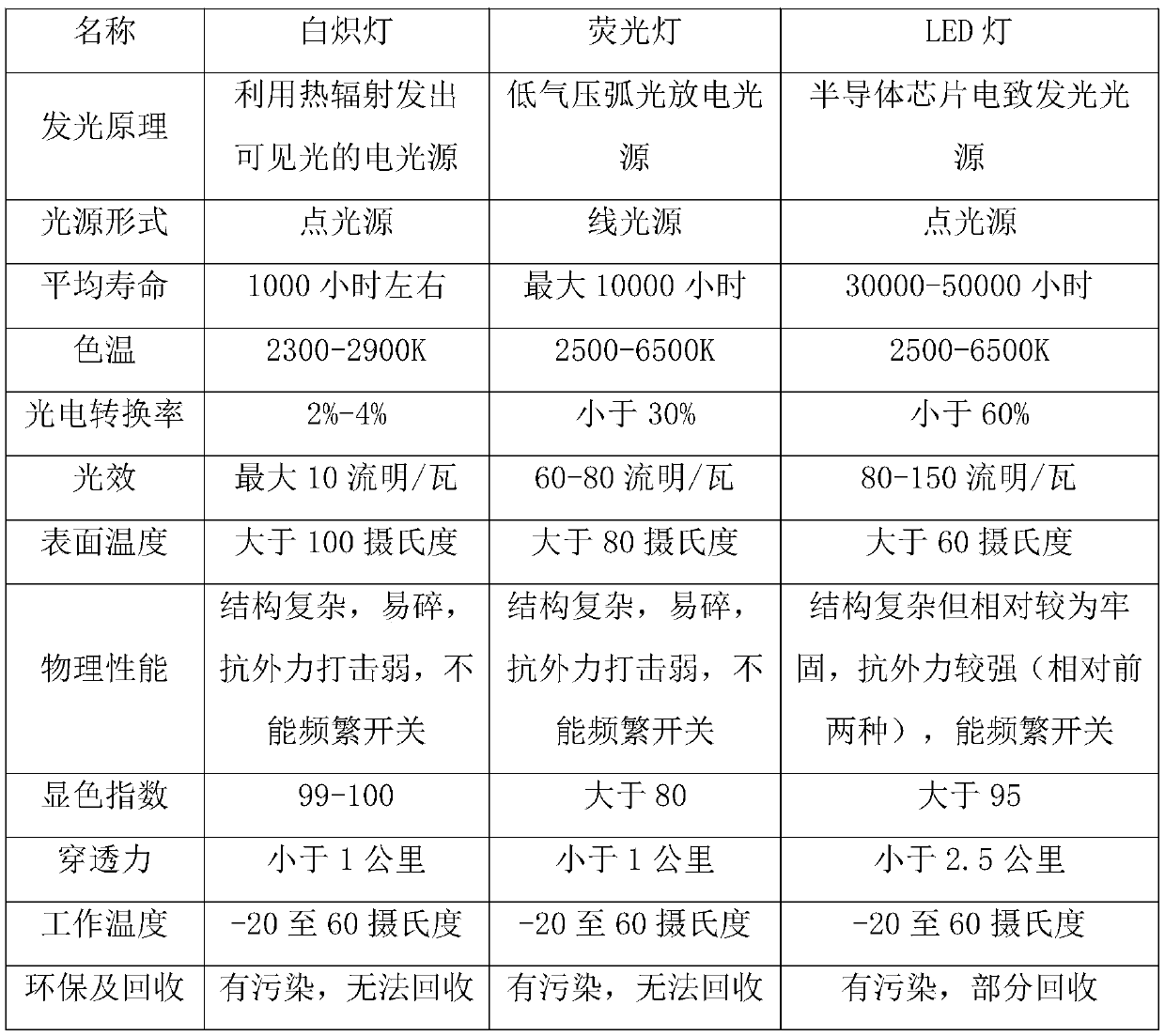

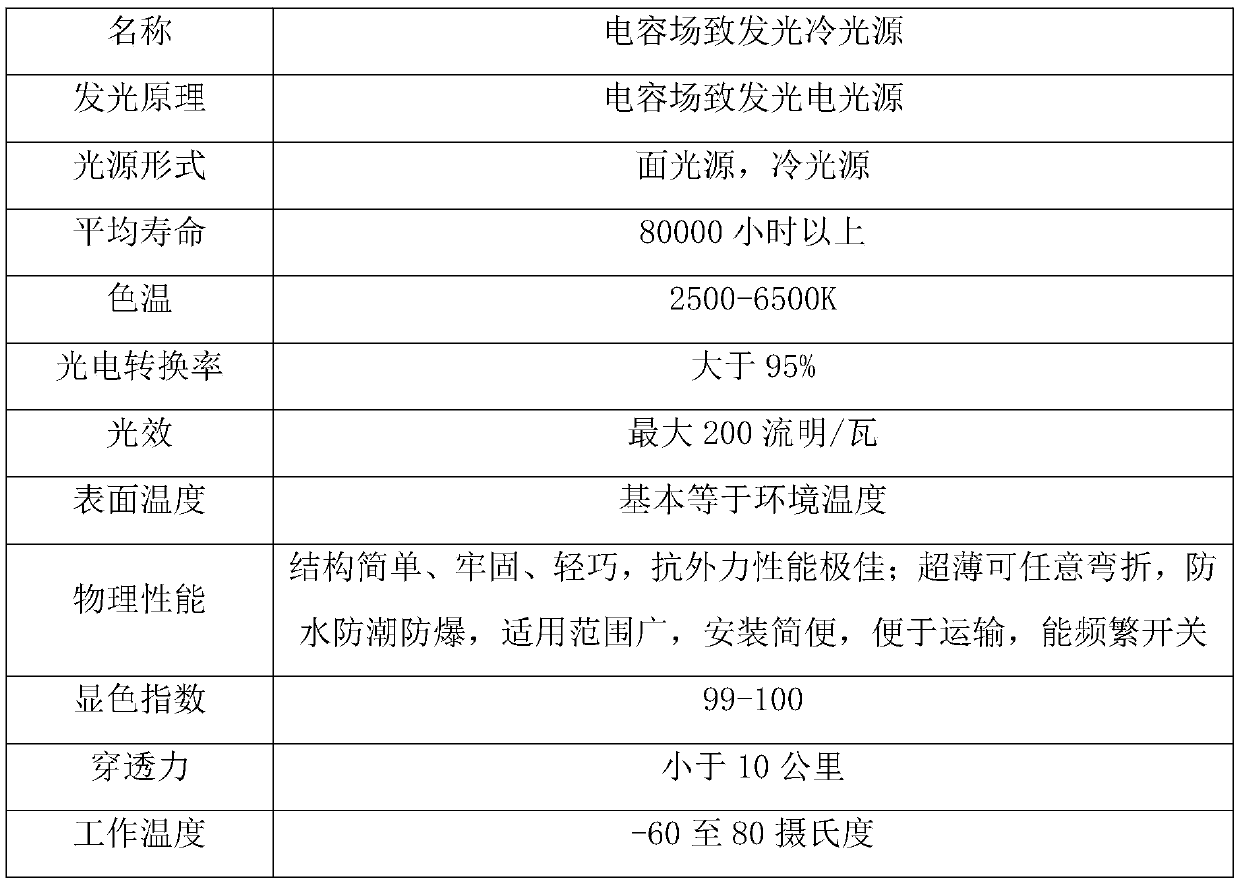

A technology of electroluminescence and cold light source, which is applied in the direction of light source, fluorescent light, lighting and heating equipment, etc. It can solve the problems of no color rendering index and high color temperature unsuitable for human eyes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

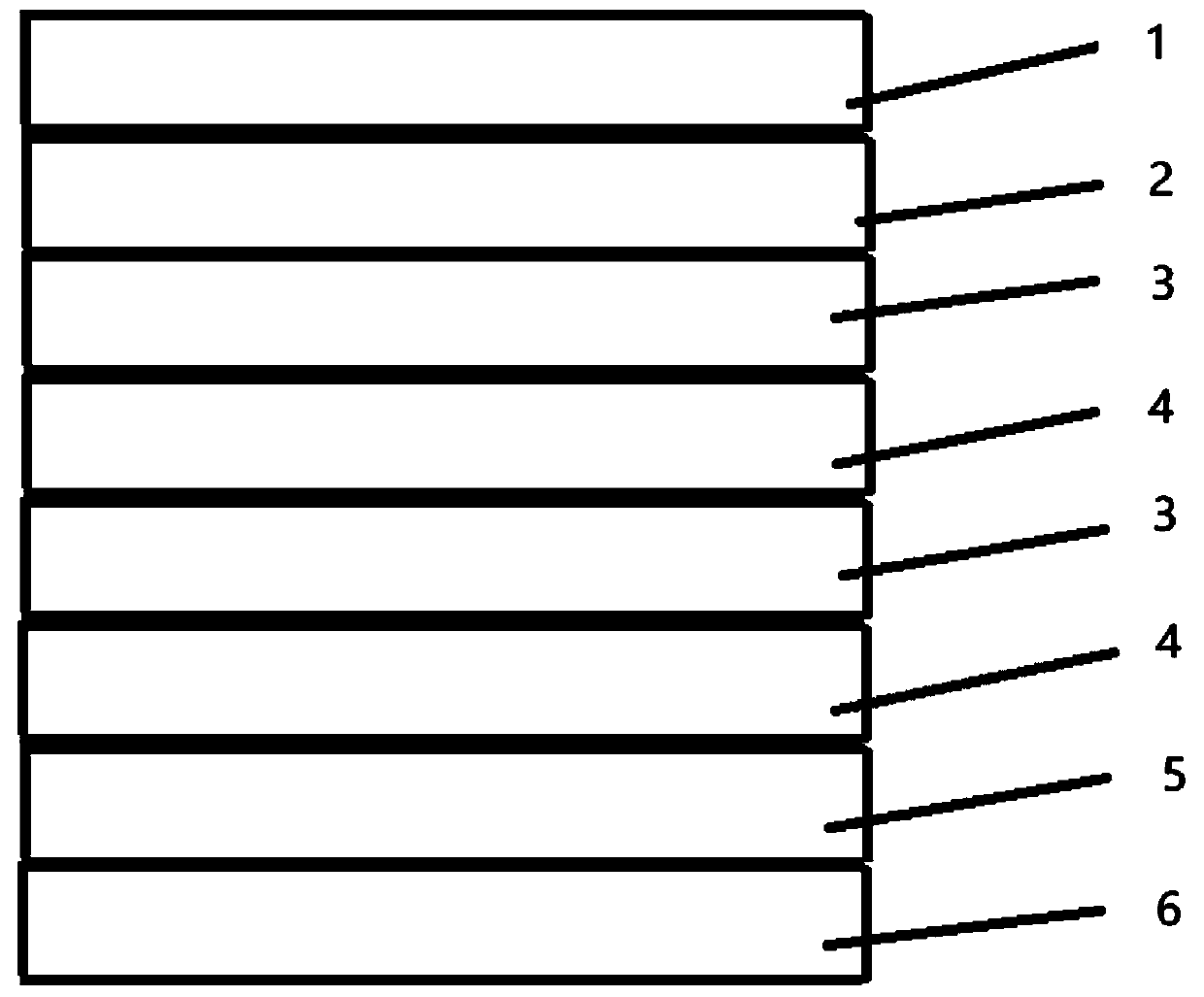

Image

Examples

preparation example Construction

[0105] The preparation method of the capacitive electroluminescent cold light source of the present invention comprises the following steps:

[0106] S1. Configuration of slurry:

[0107]1) The raw materials in the following parts by weight: 65-75 parts of silver, 7-13 parts of lead, 15-25 parts of bismuth borosilicate, 140-160 parts of epoxy resin, 40-60 parts of cyclohexanone and 280 parts of water -320 parts are configured as conductive silver paste;

[0108] 2) Mix the following raw materials in parts by weight: 8-14 parts of epoxy resin, 8-12 parts of cyclohexanone, 6-10 parts of alkylbenzimidazole, 5-9 parts of acetic acid, and 60-70 parts of water to prepare solution, and then add 180-220g zinc sulfide and cupric chloride mixed powder in every liter of solution, the weight ratio of described zinc sulfide and cupric chloride is 2.5-3.5:1, can obtain the head and tail layer of light-emitting layer after stirring evenly and drying slurry;

[0109] 3) Mix 8-14 parts of e...

Embodiment 1

[0137] A method for preparing a capacitive electroluminescent cold light source, comprising the steps of:

[0138] S1. Configuration of slurry:

[0139] 1) The following raw materials in parts by weight: 65 parts of silver, 7 parts of lead, 15 parts of bismuth borosilicate, 140 parts of epoxy resin, 40 parts of cyclohexanone and 280 parts of water are configured into conductive silver paste;

[0140] 2) The following raw materials in parts by weight: 8 parts of epoxy resin, 8 parts of cyclohexanone, 6 parts of alkylbenzimidazole, 5 parts of acetic acid, and 60 parts of water are mixed and configured into a solution, and then 180 g of vulcanization is added in every liter of the solution Zinc and cupric chloride mixed powder, the weight ratio of described zinc sulfide and cupric chloride is 2.5:1, can obtain the slurry of luminescent layer head and tail layer after stirring evenly and drying;

[0141] 3) Mix 8 parts of epoxy resin, 8 parts of cyclohexanone, 6 parts of alkylben...

Embodiment 2

[0160] A method for preparing a capacitive electroluminescent cold light source, comprising the steps of:

[0161] S1. Configuration of slurry:

[0162]1) The following raw materials in parts by weight: 75 parts of silver, 13 parts of lead, 25 parts of bismuth borosilicate, 160 parts of epoxy resin, 60 parts of cyclohexanone and 320 parts of water are configured into a conductive silver paste slurry;

[0163] 2) The raw materials in the following parts by weight: 14 parts of epoxy resin, 12 parts of cyclohexanone, 10 parts of alkylbenzimidazole, 9 parts of acetic acid, and 70 parts of water are mixed and configured into a solution, and then 220 g of vulcanization is added to each liter of the solution Zinc and cupric chloride mixed powder, the weight ratio of described zinc sulfide and cupric chloride is 3.5:1, can obtain the slurry of head and tail layer of luminous layer after stirring evenly and drying;

[0164] 3) Mix 14 parts of epoxy resin, 12 parts of cyclohexanone, 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com