High photoelectric conversion efficiency bi 2 moo 6 Photoanode and its preparation method and application

A technology of photoelectric conversion efficiency and photoanode, which is applied in the field of photoelectrochemistry, can solve the problems of small optical flow and low quantum efficiency, and achieve the effects of short time consumption, simple preparation method, and large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

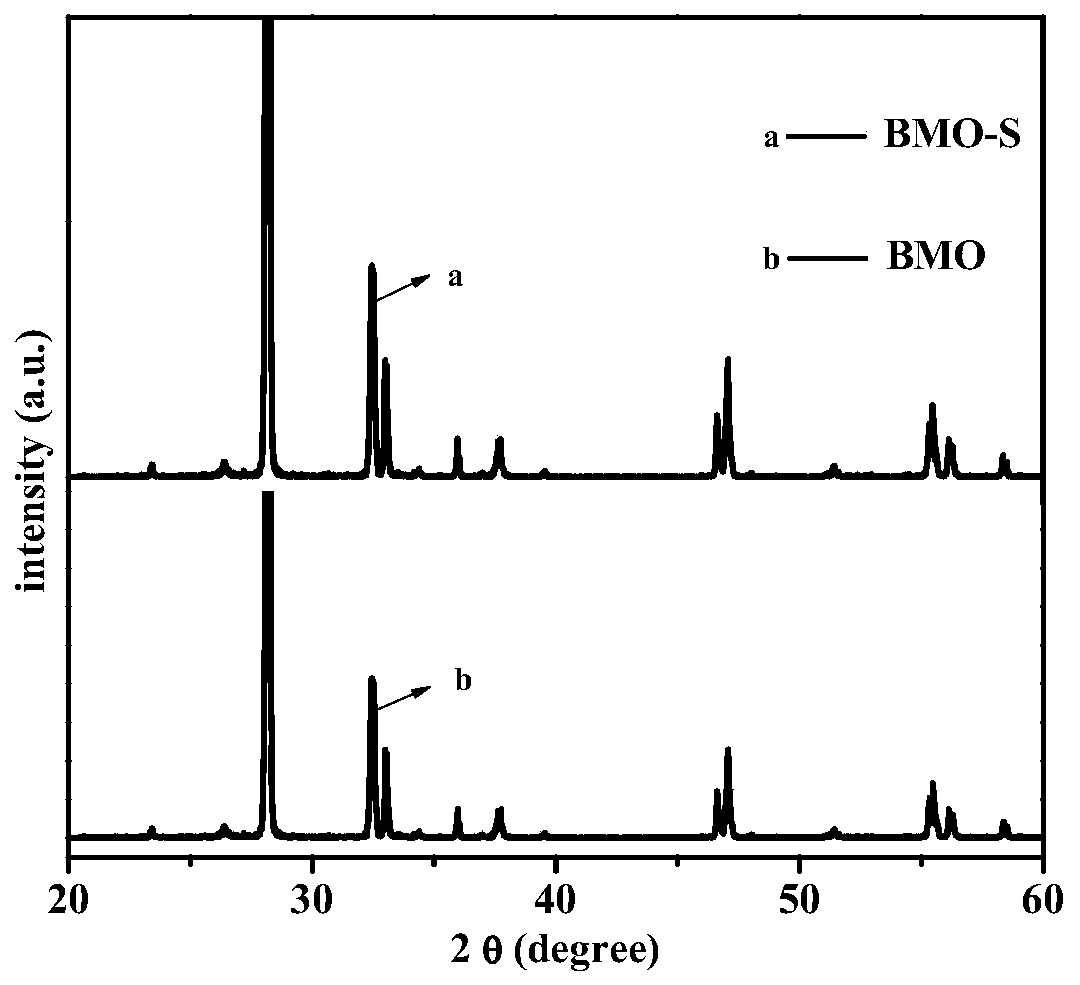

[0022] Example 1 Bi 2 MoO 6 Preparation of photoanode

[0023] (1) Bi 2 MoO 6 Preparation of powder:

[0024] 1) Take 2.425g Bi(NO 3 ) 3 ·5H 2 O and 0.442g (NH 4 ) 6 Mo 7 o 24 4H 2 O was respectively dissolved in a mixed solution of 15ml deionized water and ethanol (v:v=1:1), and magnetically stirred for 15min at the same time;

[0025] 2) The above two solutions were mixed and stirred for 20 minutes, and the resulting solution was transferred to a 50ml stainless steel autoclave, placed in a muffle furnace, and heated at 160°C for 15 hours;

[0026] 3) After cooling to room temperature, the samples were taken out for centrifugation, washed three times with deionized water and ethanol to remove residues, and then dried at 70°C. Finally, a yellow powder is obtained as Bi 2 MoO 6 .

[0027] (2) High photoelectric conversion efficiency Bi 2 MoO 6 Preparation of photoanode (BMO-S):

[0028] 1) Magnetron sputtering deposition process: First, install Bi 2 MoO 6 T...

Embodiment 2

[0035] Example 2 Bi 2 MoO 6 Application of photoanode film

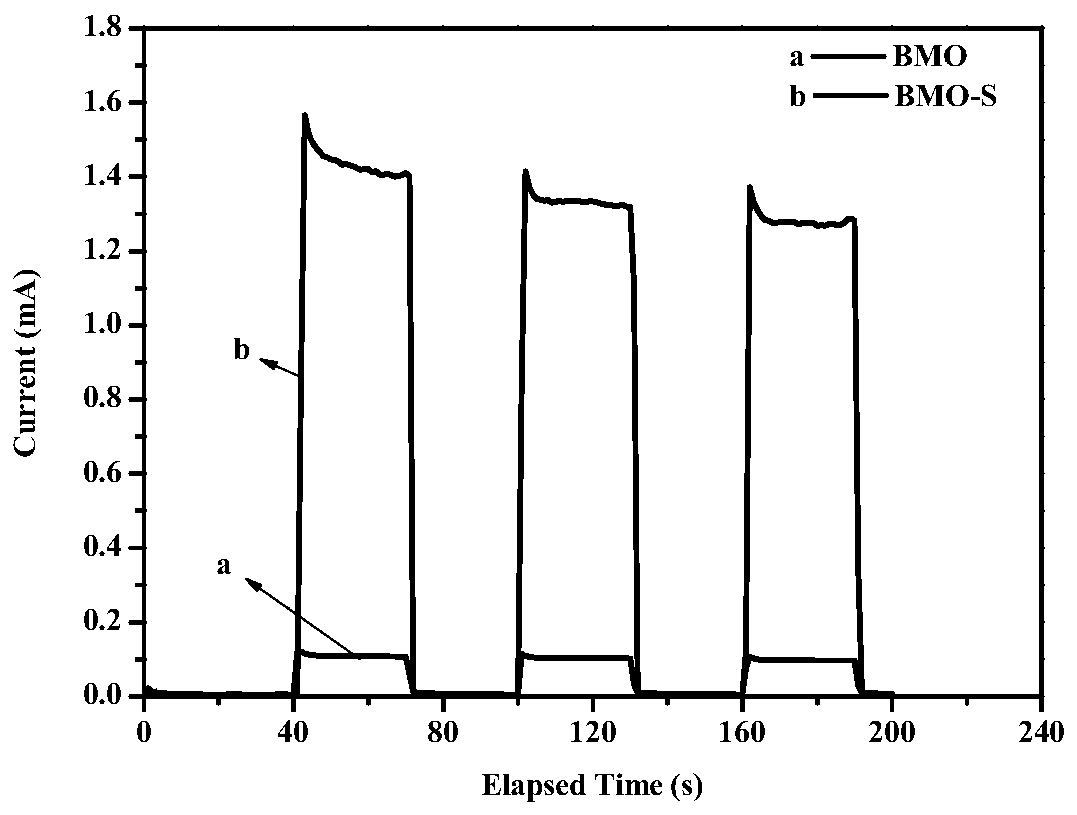

[0036] The BMO and BMO-S photoanodes prepared in Example 1 were subjected to a series of photoelectrochemical performance tests such as photocurrent, impedance, and quantum efficiency.

[0037] All electrochemical experiments were carried out in an electrochemical workstation (Princeton Applied Research 2273) with a three-electrode system. The sample film is used as the working electrode, the platinum sheet is used as the counter electrode, Ag / AgCl is used as the reference electrode, the electrolyte is 0.5M sodium sulfate, and the light irradiation area of the sample is 1cm 2 .

[0038] Photocurrent test: the light source is 300W xenon lamp, the bias voltage is 1.18v vs.V RHE , the measured results are as image 3 As shown, the results show that the photocurrent of BMO-S is 13 times that of BMO.

[0039] Electrochemical impedance spectroscopy (EIS) test: the fixed voltage is 0V vs.V oc , the frequency range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com