A kind of solar graphene battery

A graphene and solar energy technology, applied in the field of solar cells, can solve the problems of unfavorable large-scale production and application, low photoelectric conversion efficiency, and high price, and achieve the effect of improving photoelectric conversion efficiency, improving photoelectric conversion efficiency, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

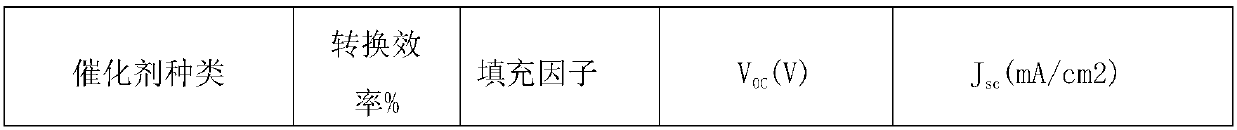

Embodiment 1

[0027] A kind of solar graphene battery is prepared by transparent conductive glass substrate, porous graphene composite thin film and dye sensitizer, electrolytic solution, and the opposite electrode prepared by transparent conductive glass substrate, composite catalytic layer and porous carbon film and It is composed of a sealed and fixed film shell, the photoanode is prepared by coating a porous graphene composite film on the surface of a transparent conductive glass substrate, and the dye sensitizer is firmly attached to the porous graphene composite film; The counter electrode is prepared by coating the carbon slurry on the surface of a transparent conductive glass substrate to form a porous carbon film, and coating the composite catalyst on the porous carbon film to form a composite catalytic layer, while the electrolyte solution is placed in a dye sensitizer and a composite Between the catalytic layers, the whole battery is sealed and fixed as a whole through a thin-film...

Embodiment 2

[0037] A kind of solar graphene battery is prepared by transparent conductive glass substrate, porous graphene composite thin film and dye sensitizer, electrolytic solution, and the opposite electrode prepared by transparent conductive glass substrate, composite catalytic layer and porous carbon film and It is composed of a sealed and fixed film shell, the photoanode is prepared by coating a porous graphene composite film on the surface of a transparent conductive glass substrate, and the dye sensitizer is firmly attached to the porous graphene composite film; The counter electrode is prepared by coating the carbon slurry on the surface of a transparent conductive glass substrate to form a porous carbon film, and coating the composite catalyst on the porous carbon film to form a composite catalytic layer, while the electrolyte solution is placed in a dye sensitizer and a composite Between the catalytic layers, the whole battery is sealed and fixed as a whole through a thin-film...

Embodiment 3

[0047] A kind of solar graphene battery is prepared by transparent conductive glass substrate, porous graphene composite thin film and dye sensitizer, electrolytic solution, and the opposite electrode prepared by transparent conductive glass substrate, composite catalytic layer and porous carbon film and It is composed of a sealed and fixed film shell, the photoanode is prepared by coating a porous graphene composite film on the surface of a transparent conductive glass substrate, and the dye sensitizer is firmly attached to the porous graphene composite film; The counter electrode is prepared by coating the carbon slurry on the surface of a transparent conductive glass substrate to form a porous carbon film, and coating the composite catalyst on the porous carbon film to form a composite catalytic layer, while the electrolyte solution is placed in a dye sensitizer and a composite Between the catalytic layers, the whole battery is sealed and fixed as a whole through a thin-film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com